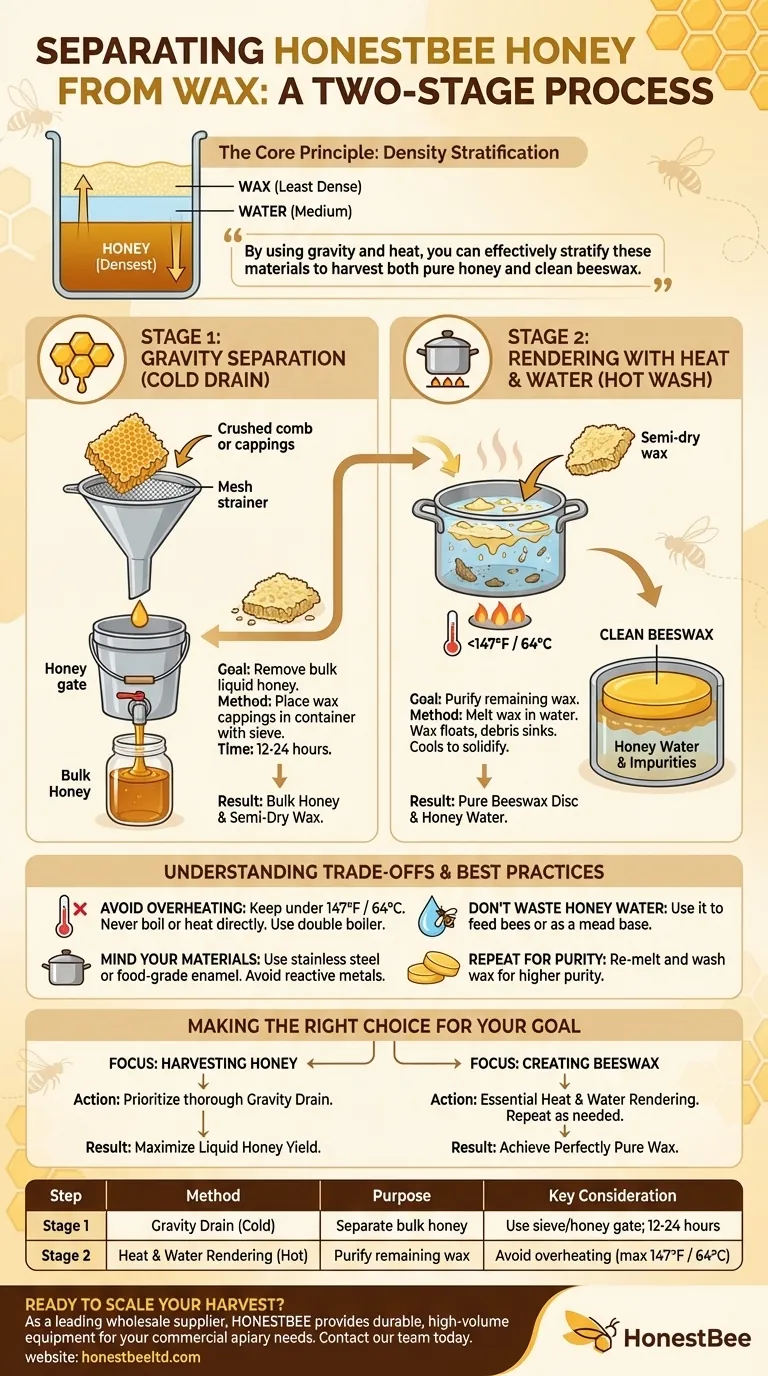

To separate honey from wax, you will use a two-stage process based on their different densities. First, allow the bulk of the honey to drain away from the wax cappings or crushed comb using gravity. Then, use heat and water to melt and "render" the remaining wax, which will float to the top, separating it cleanly from any residual honey and impurities.

The entire separation process hinges on a simple principle: honey is the densest, wax is the least dense, and water sits in the middle. By using gravity and heat, you can effectively stratify these materials to harvest both pure honey and clean beeswax.

The Two-Stage Separation Process

For the most effective results, beekeepers use a combination of a "cold" gravity-based method followed by a "hot" rendering method. This maximizes the yield and purity of both products.

Stage 1: Gravity Separation (The Cold Drain)

This initial step is designed to get the vast majority of the liquid honey out of the comb with minimal effort.

You simply place your wax cappings or crushed honeycomb into a container with a filter or sieve at the bottom, like a bucket with a honey gate or a large strainer placed over a clean bucket.

Over a period of 12-24 hours, gravity will do the work. The heavy, viscous honey will slowly drip down and collect in the bottom container, leaving behind a semi-dry mass of wax.

Stage 2: Rendering with Heat & Water (The Hot Wash)

This second stage is for purifying the wax that was left behind after the gravity drain. This wax still contains trapped honey, pollen, and other hive debris.

The process involves melting the wax in water. As the wax melts, the less-dense, oil-based wax will float on top of the water.

Heavier impurities and water-soluble honey will sink to the bottom or dissolve into the water itself. Once the mixture cools, the purified wax will solidify into a clean disc on the surface, which can be easily lifted off.

Understanding the Trade-offs and Best Practices

Achieving a clean separation requires attention to detail. Avoiding common mistakes is crucial for maintaining the quality of both your honey and your wax.

Avoid Overheating the Wax

Beeswax has a relatively low melting point (around 144-147°F or 62-64°C). Never boil the wax or heat it directly in a pot without water.

Overheating can darken the wax, destroy its pleasant aroma, and degrade its quality. A gentle double boiler or a dedicated wax melter is the ideal tool.

Mind Your Materials

Use stainless steel or food-grade enamel pots for melting wax. Other metals, like iron or brass, can react with the wax and cause discoloration.

The water used for rendering will absorb the remaining honey. Do not discard it. This sweet "honey water" can be used to feed bees or as a base for making mead.

Making the Right Choice for Your Goal

Your approach depends on whether your priority is harvesting the honey or purifying the wax.

- If your primary focus is harvesting liquid honey: The gravity separation stage is the most important step. Let the honey drain thoroughly before you even consider processing the wax.

- If your primary focus is creating clean beeswax for candles or crafts: The heat and water rendering stage is essential. You may even need to repeat this washing and melting process two or three times to achieve a perfectly pure block of wax.

Ultimately, mastering this two-stage process allows you to respectfully use everything the bees provide, ensuring nothing goes to waste.

Summary Table:

| Step | Method | Purpose | Key Consideration |

|---|---|---|---|

| Stage 1 | Gravity Drain (Cold) | Separate bulk honey from wax | Use a sieve or honey gate; takes 12-24 hours |

| Stage 2 | Heat & Water Rendering (Hot) | Purify remaining wax from honey/debris | Avoid overheating (max 147°F / 64°C) |

Ready to scale your honey and wax harvesting? As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-volume equipment you need—from honey gates and strainers to commercial wax melters. Let our expertise help you maximize your yield and efficiency. Contact our team today to discuss your operation's needs.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Honey Press Wax Press with Tank

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What happens to the remaining wax in the Wax Screw Presses set? A Guide to Efficient Honey & Wax Separation

- In what scenarios is a Honey Presser used? Essential Recovery & Processing Solutions for Modern Apiaries

- What is the recommended comb temperature for optimal honey press efficiency? Preserve Quality & Maximize Yield

- What are the requirements for squeezing Apis dorsata honeycombs? Ensure Pure Honey Sampling for Pollen Analysis

- What happens to the wax after pressing in a honey press? A Guide to Maximizing Your Hive's Yield

- What is the primary function of a Wax Screw Press set? Maximize Honey Yield and Wax Efficiency

- What is the most common type of honey press? Discover the Bucket Honey Press for Efficient Small-Scale Extraction

- What technical role does a honey press play in the honey refining process? Maximize Your Honey Yield and Wax Quality