At its core, a manual honey extractor operates by using a hand crank to spin honey frames at high speed. This rotation generates powerful centrifugal force, which flings the liquid honey out from the uncapped honeycomb cells. The honey then collects at the bottom of the extractor's drum, ready to be drained.

A manual extractor leverages simple mechanics and human power to separate honey from the comb. While effective and affordable, its value is directly tied to small-scale operations where the investment of physical effort is an acceptable trade-off for low cost and simplicity.

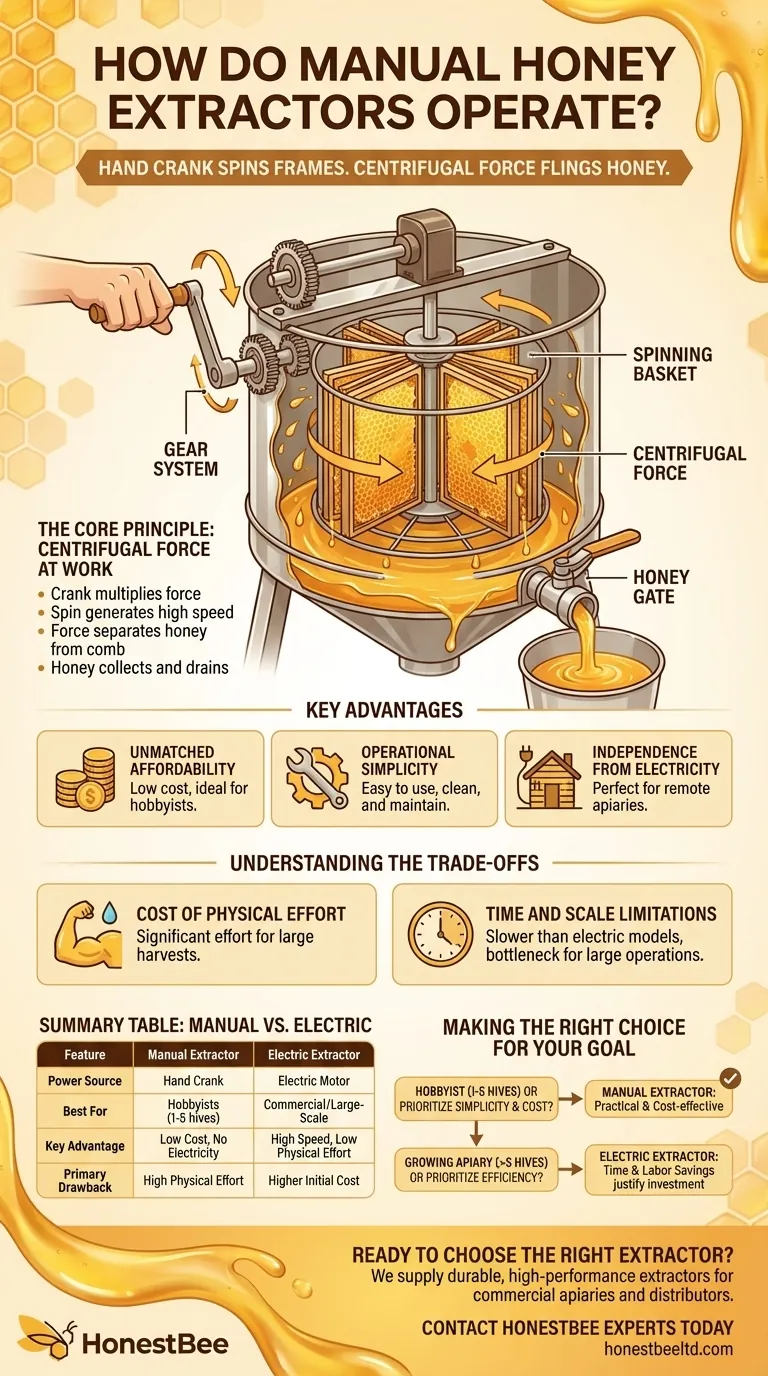

The Core Principle: Centrifugal Force at Work

A manual extractor is a simple yet brilliant application of physics. Understanding how it works reveals why it has been a staple for beekeepers for generations.

From Crank to Spin

The operator turns a handle or hand crank located on the top or side of the unit. This crank is connected via a gear system to a central rotor inside the main drum. The gearing multiplies the force, allowing a relatively easy crank motion to generate a high-speed spin.

Separating Honey from Comb

Frames of uncapped honeycomb are placed vertically into a basket or cage that is part of the central rotor. As the basket spins, centrifugal force acts on the honey, pulling it outward and away from the center. The force is strong enough to sling the liquid honey out of the wax cells while leaving the delicate comb structure largely intact.

Collection and Draining

The extracted honey hits the inner wall of the cylindrical drum. Pulled by gravity, it then runs down the smooth surface and pools at the conical base of the extractor. A valve at the bottom, known as a honey gate, is opened to drain the pure, filtered honey into a bucket.

Key Advantages of a Manual System

For many beekeepers, the manual approach is not a limitation but a deliberate choice driven by several key benefits.

Unmatched Affordability

Manual extractors are significantly less expensive than their electric counterparts. This makes them the ideal entry point for hobbyists or beekeepers with only a few hives, as the initial investment is minimal.

Operational Simplicity

With fewer moving parts and no electronics, manual extractors are straightforward to operate, clean, and maintain. Their simple design also means there is less that can break down over time.

Independence from Electricity

The ability to operate without a power source is a major advantage. This makes manual extractors perfect for use in remote apiaries, off-grid homesteads, or any location where access to electricity is unreliable or inconvenient.

Understanding the Trade-offs

The primary drawback of a manual extractor is the direct trade-off between cost and labor. The money you save on the purchase price is paid back in physical effort.

The Cost of Physical Effort

Cranking an extractor, especially when it is full of heavy honey frames, requires significant and sustained physical effort. Extracting from more than a few hives can become a time-consuming and exhausting task.

Time and Scale Limitations

The process is inherently slower than using an automated electric model. For commercial operations or beekeepers with a large number of hives, the time spent on manual extraction can become a major bottleneck in production.

When to Consider an Electric Model

An electric extractor automates the spinning process with a motor. While more expensive, it dramatically reduces labor and speeds up the entire workflow, making it a logical upgrade for growing apiaries or commercial producers where efficiency is paramount.

Making the Right Choice for Your Goal

The decision between a manual and electric extractor is a practical one based entirely on the scale of your operation and your personal goals.

- If you are a hobbyist with 1-5 hives: A manual extractor offers the most practical and cost-effective solution for your needs.

- If your apiary is growing beyond 5 hives: The time and labor savings from an electric model will likely justify the higher initial investment.

- If you prioritize operational simplicity and cost over speed: The manual extractor remains a reliable and highly effective tool regardless of hive count.

Understanding this fundamental balance between manual effort and automated efficiency is the key to selecting the perfect tool for your beekeeping journey.

Summary Table:

| Feature | Manual Extractor | Electric Extractor |

|---|---|---|

| Power Source | Hand Crank | Electric Motor |

| Best For | Hobbyists (1-5 hives) | Commercial/Large-Scale Operations |

| Key Advantage | Low Cost, No Electricity Needed | High Speed, Low Physical Effort |

| Primary Drawback | High Physical Effort | Higher Initial Cost |

Ready to choose the right extractor for your apiary?

Whether you're a hobbyist starting out or a commercial producer scaling up, HONESTBEE has the equipment you need. We supply durable, high-performance manual and electric honey extractors to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations.

Let us help you streamline your honey harvest. Contact our experts today to discuss your specific needs and discover the right solution for your beekeeping success.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How do you manually extract honey? Choose the Best Method for Your Hive

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently

- What equipment is used for honey harvest? Essential Tools for Every Beekeeper

- What should be considered when harvesting honey from multiple hives? Scale Your Harvest Efficiently

- How do you collect honey at home? A Beginner's Guide to Harvesting from Your Hive