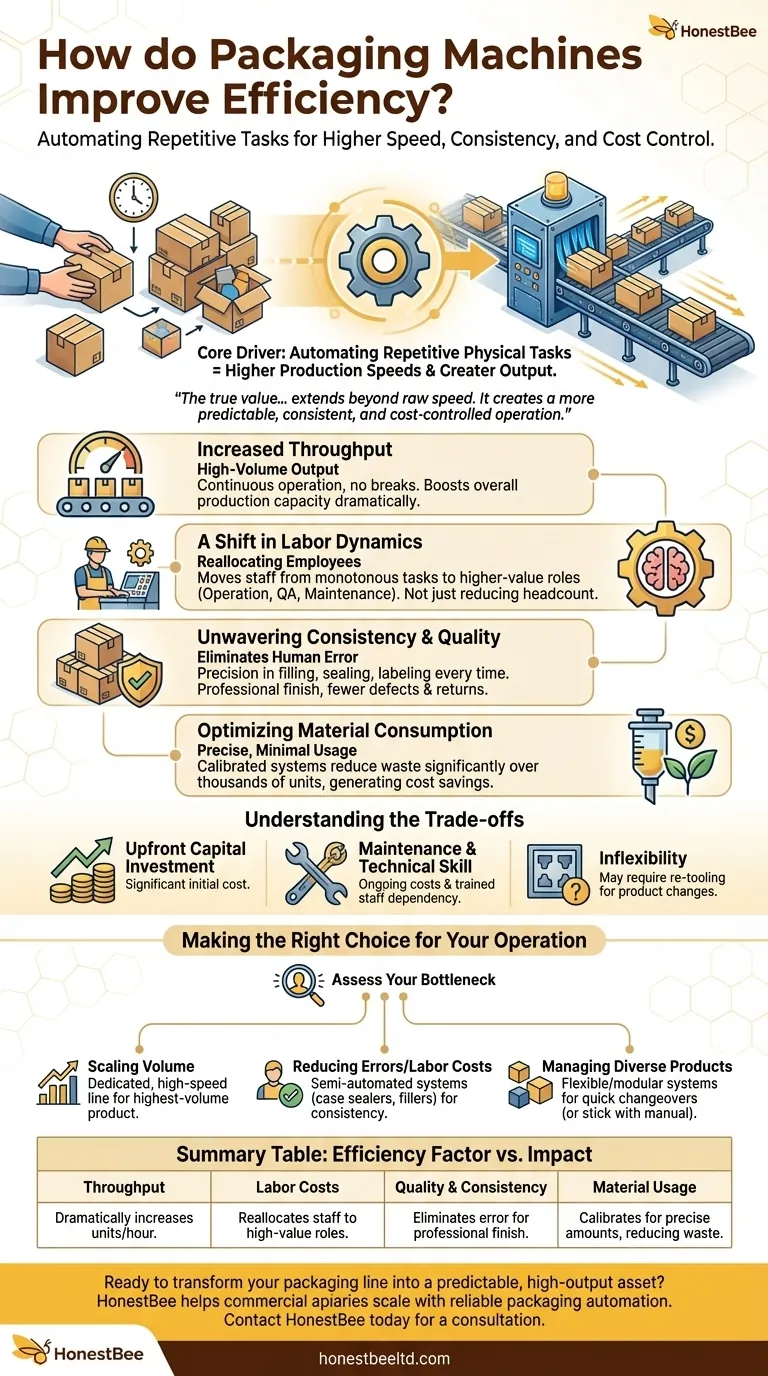

In the simplest terms, packaging machines improve efficiency by automating repetitive physical tasks. This allows for significantly higher production speeds and greater output than any manual process, directly addressing the core challenge of scaling operations while controlling labor costs.

The true value of packaging automation, however, extends beyond raw speed. It creates a more predictable, consistent, and cost-controlled operation by minimizing human error, optimizing material usage, and reallocating skilled labor to higher-value activities.

Beyond Speed: Deconstructing Packaging Efficiency

While increased speed is the most obvious benefit, a comprehensive view of efficiency includes labor, quality, and material costs. Automation impacts every one of these areas.

The Core Driver: Increased Throughput

Automated systems are engineered for one primary purpose: high-volume output. Unlike human workers, machines can operate continuously at a consistent pace without fatigue, breaks, or shift changes.

This continuous operation results in a dramatic increase in the number of units packaged per hour, directly boosting the overall production capacity of your entire facility.

A Shift in Labor Dynamics

Automation fundamentally changes your relationship with labor costs. It replaces expensive, repetitive manual labor with a predictable capital expense.

This doesn't always mean reducing headcount. It often involves reallocating employees from monotonous packing tasks to more valuable roles like machine operation, quality assurance, or maintenance, where their cognitive skills provide a greater return.

Unwavering Consistency and Quality

A machine performs its task—whether it's filling, sealing, or labeling—with the exact same precision every single time. This eliminates human error and variability.

The result is a more professional-looking final product, a drastic reduction in product damage during packaging, and fewer costly returns or rework due to packaging defects.

Optimizing Material Consumption

Manual packaging often leads to material waste. Employees may use too much tape, an incorrect amount of fill, or excess wrapping film out of habit or caution.

Automated systems can be calibrated to use the precise, minimal amount of material required for each package. Over thousands of units, this level of control generates significant cost savings by reducing waste.

Understanding the Trade-offs

Adopting automation is a strategic decision, not a simple upgrade. It requires a clear understanding of the associated costs and limitations.

The Upfront Capital Investment

The primary barrier to automation is the significant initial cost. A packaging machine is a major capital expenditure that must be justified by a clear return on investment (ROI) projection.

Maintenance and Technical Skill

These machines require ongoing maintenance and specialized technical skill to operate and repair. This introduces a new operational cost and a dependency on trained technicians, whether in-house or from the vendor.

The Challenge of Inflexibility

Many packaging machines are designed for a specific product size, shape, or packaging type. While human packers can adapt to changes instantly, a machine may require expensive and time-consuming re-tooling.

This lack of flexibility can be a major drawback for businesses with diverse or frequently changing product lines.

Making the Right Choice for Your Operation

The best approach depends entirely on your specific operational goals. Assess your primary bottleneck before investing.

- If your primary focus is scaling production volume: A dedicated, high-speed automated line designed for your highest-volume product will deliver the clearest and fastest return.

- If your primary focus is reducing errors and labor costs: Even semi-automated systems, like case sealers or fillers, can introduce consistency and free up staff for a much lower initial investment.

- If your primary focus is managing diverse products: Consider more flexible or modular automated systems that are designed for quick changeovers, or accept that a fully manual process may still be the most efficient solution.

Ultimately, integrating the right packaging automation is a strategic decision that transforms your operational efficiency from a variable cost into a predictable asset.

Summary Table:

| Efficiency Factor | Impact of Packaging Machines |

|---|---|

| Throughput | Dramatically increases units packaged per hour with continuous operation. |

| Labor Costs | Replaces repetitive manual tasks, allowing staff reallocation to higher-value roles. |

| Quality & Consistency | Eliminates human error for a professional finish and fewer defects. |

| Material Usage | Calibrates to use precise amounts, significantly reducing waste and cost. |

Ready to transform your packaging line into a predictable, high-output asset?

At HONESTBEE, we understand that commercial apiaries and beekeeping equipment distributors need reliable, efficient operations to scale. The right packaging automation is key to boosting your throughput, controlling labor costs, and ensuring your products—from honey jars to hive components—are consistently and professionally packaged.

Let our wholesale-focused expertise help you select the packaging machinery that delivers a clear return on investment. Contact HONESTBEE today for a consultation and discover how we can help you package your success.

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Professional Durable Customizable Blister Packing Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Automatic In-Line Flat Surface Labeling Machine

People Also Ask

- What kind of machine is used to seal? Find the Right Sealing Technology for Your Needs

- How does a sealing machine work? Ensure Product Integrity with a Perfect Hermetic Seal

- What are the different types of sealer machines? Find the Right Sealer for Your Operation

- What are the causes and solutions for leakage in a stick pack seal? Fix Pressure, Temperature, and Hardware Issues

- How do I choose a heat sealer? A Guide to Matching the Right Machine to Your Needs