At its core, a water jacket melter functions like a large, industrial-grade double boiler. It uses a surrounding layer, or "jacket," of heated water to gently and evenly melt the contents of an inner tank. This design provides uniform heat transfer and prevents scorching by ensuring the product never comes into contact with a direct heating element.

The fundamental purpose of the water jacket is to create a thermal buffer. This buffer uses water's boiling point as a natural temperature ceiling, making it the ideal system for melting temperature-sensitive materials without the risk of overheating.

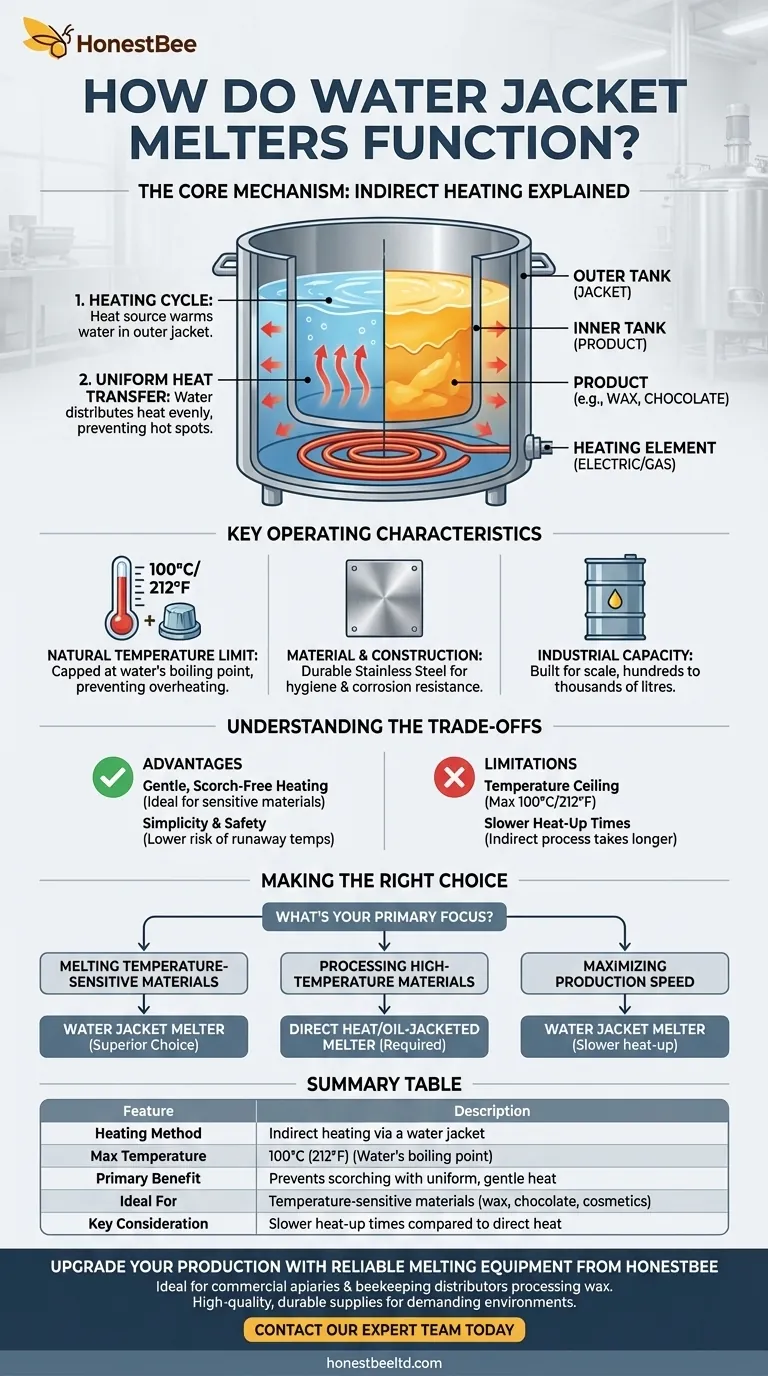

The Core Mechanism: Indirect Heating Explained

The genius of the water jacket melter lies in its simplicity. By separating the heat source from the product tank, it solves the most common problem in melting: hot spots that burn the material.

The "Jacket" Concept

A water jacket melter consists of two tanks, one nested inside the other. The inner tank holds the product you want to melt (like wax, chocolate, or soap base), while the space between the inner and outer tank is filled with water.

The Heating Cycle

An electric heating element or gas burner heats the water within the outer jacket. As the water's temperature rises, it transfers its thermal energy uniformly across the entire surface of the inner tank wall.

This process heats the product from all sides simultaneously, not just from the bottom.

Uniform Heat Transfer

Direct heat melters apply intense heat to one specific area, creating hot spots that can easily scorch the product. The water in a jacketed melter acts as a medium, distributing that same heat energy evenly.

This results in a consistent, gentle melt without any localized overheating.

Key Operating Characteristics

The design of a water jacket melter dictates its primary benefits and limitations, which are crucial to understand for proper application.

The Natural Temperature Limit

The most important feature is its temperature cap. At standard atmospheric pressure, water boils at 100°C (212°F) and cannot get any hotter.

This physical property provides a built-in safety feature, making it impossible to accidentally overheat and ruin sensitive ingredients.

Material and Construction

These melters are typically constructed from stainless steel. This material is chosen for its durability, resistance to corrosion, and ease of cleaning, which is especially important in food or cosmetic production.

Industrial Capacity

While the principle is simple, these are not kitchen appliances. Water jacket melters are built for scale, with capacities often ranging from hundreds to thousands of litres, serving significant production needs.

Understanding the Trade-offs

No single technology is perfect for every task. The key is to align the tool with the job.

Advantage: Gentle, Scorch-Free Heating

This is the primary reason to choose a water jacket melter. It is the definitive solution for materials that degrade or burn easily, such as chocolate, cosmetics, lotions, and natural waxes.

Advantage: Simplicity and Safety

The inherent temperature limit makes these systems relatively simple and safe to operate. There is less risk of runaway temperatures compared to direct heat or oil-jacketed systems.

Limitation: Temperature Ceiling

The most obvious drawback is the temperature limit. These melters are completely unsuitable for any material that requires a melting point above 100°C (212°F).

Limitation: Slower Heat-Up Times

The indirect heating process is less efficient than direct heat. You must first heat the entire volume of water in the jacket, which then heats the product. This cycle takes longer than applying a heating element directly to the product tank.

Making the Right Choice for Your Application

Selecting the correct melter comes down to understanding the thermal properties of your material.

- If your primary focus is melting temperature-sensitive materials: The water jacket melter is the superior choice for its gentle, even heating that prevents scorching.

- If your primary focus is processing high-temperature materials: You must use a direct heat or oil-jacketed melter to reach temperatures above 100°C (212°F).

- If your primary focus is maximizing production speed: Be prepared for the slower heat-up and melt times inherent to a water jacket system compared to direct heat alternatives.

Ultimately, a water jacket melter provides unparalleled control and safety for delicate materials by mastering the principle of indirect heat.

Summary Table:

| Feature | Description |

|---|---|

| Heating Method | Indirect heating via a water jacket |

| Max Temperature | 100°C (212°F) - Limited by water's boiling point |

| Primary Benefit | Prevents scorching with uniform, gentle heat |

| Ideal For | Temperature-sensitive materials (wax, chocolate, cosmetics) |

| Key Consideration | Slower heat-up times compared to direct heat systems |

Upgrade Your Production with Reliable Melting Equipment from HONESTBEE

Are you a commercial apiary or beekeeping equipment distributor looking for efficient, reliable equipment to process wax and other sensitive materials? The gentle, uniform heat of a water jacket melter is ideal for preserving the quality of your products.

HONESTBEE supplies high-quality, wholesale-focused beekeeping supplies and equipment designed for durability and performance in demanding environments. Let us help you equip your operation with the right tools for success.

Contact our expert team today to discuss your specific needs and explore our range of solutions.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- How does a steam wax melter work? A Fast, Efficient Method for High-Quality Wax

- What are the features of industrial wax melters? Unlock Precision Purity for Commercial Beeswax Production

- What are the primary products of honey bee farming besides honey? Discover the Hive's Hidden Treasures

- What is the best way to melt beeswax for candles? The Safest Method for Professional Results

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs