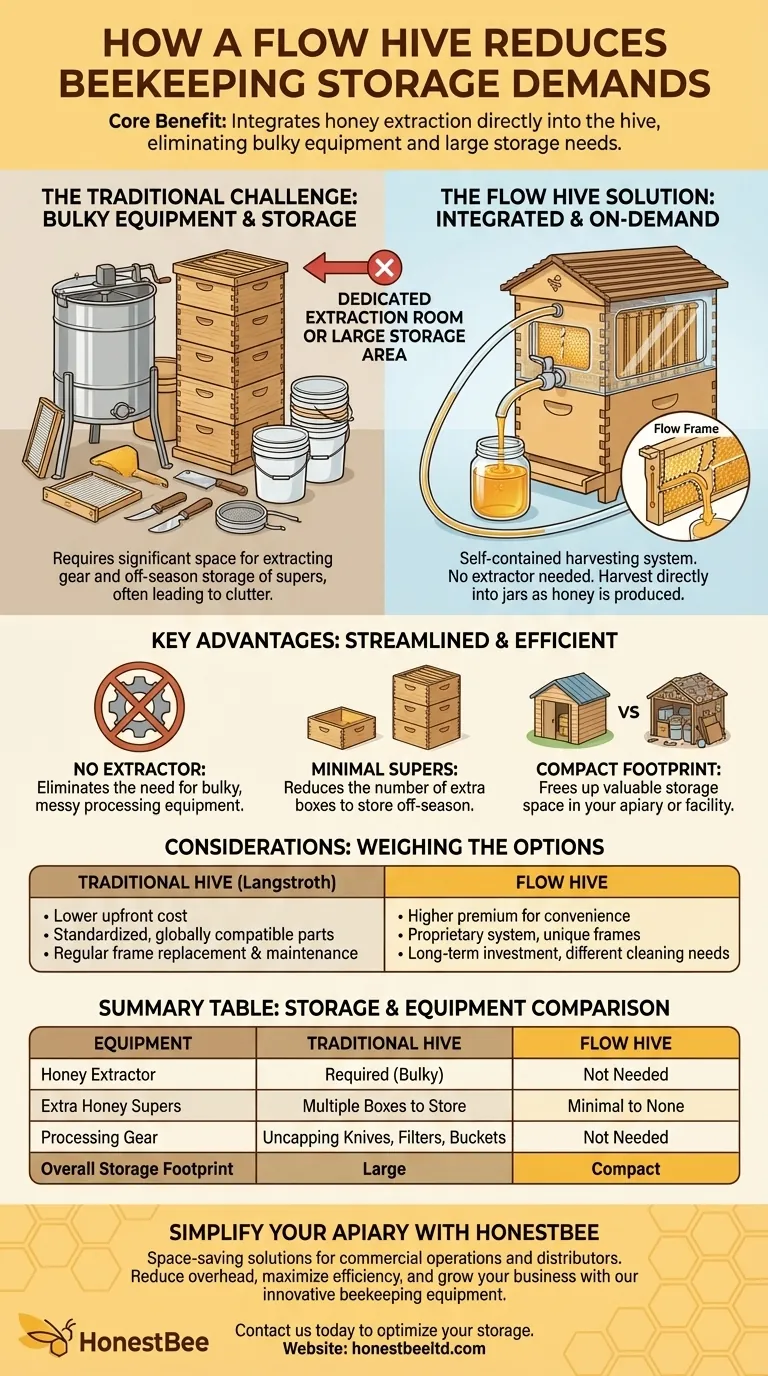

At its core, a Flow Hive reduces storage demands by integrating the honey extraction process directly into the beehive itself. This eliminates the need for the bulkiest and most space-intensive equipment associated with traditional beekeeping: a centrifugal honey extractor and the stacks of extra honey boxes, known as "supers," that you must store off-season.

The primary advantage of a Flow Hive in terms of storage is its consolidation of equipment. It effectively trades the requirement for a dedicated extraction room or large storage area for a self-contained harvesting system.

The Traditional Storage Footprint: A Langstroth Baseline

To understand the Flow Hive's benefit, you must first understand what a traditional beekeeper needs to store. The Langstroth hive is the most common example.

Storing Honey Supers

With a traditional hive, you add empty boxes (supers) on top for the bees to fill with honey. At the end of the season, you remove these heavy, honey-filled supers for harvesting.

Once harvested, these empty supers—sticky with residual honey and wax—must be cleaned and stored somewhere safe from pests and weather until the next season. A growing apiary can quickly accumulate a large stack of these boxes.

The Extractor and Processing Gear

The biggest storage challenge is the extraction equipment. Harvesting from traditional frames requires a dedicated, multi-step process.

This involves a large, often stainless steel, centrifugal extractor to spin honey out of the frames. You also need uncapping knives or scrapers, filters, and multiple buckets. This equipment is bulky, messy, and requires a significant amount of dedicated storage space.

How the Flow Hive Changes the Equation

The Flow Hive was designed specifically to eliminate the need for that separate extraction process and its associated equipment.

Integrated Extraction Mechanism

The key innovation is the Flow Frame, a partially formed plastic honeycomb that bees complete with their own wax. When you're ready to harvest, you insert a tool into the frame and turn it.

This action splits the honeycomb cells vertically, creating channels that allow the honey to flow down and out of the hive through a tube, directly into your jar. The entire extraction mechanism is contained within the hive.

On-Demand Harvesting

Because you can tap one frame at a time, you don't need to remove and handle heavy supers. You can harvest honey as the bees produce it, whenever a single frame is full.

This eliminates the need to store full, heavy boxes while waiting for a dedicated "extraction day."

Understanding the Trade-offs

While the storage savings are clear, this convenience comes with important considerations. True expertise requires weighing the pros and cons.

Space and Convenience vs. Cost

The primary trade-off is cost. A Flow Hive has a significantly higher upfront price than a basic Langstroth hive.

You are paying a premium for the convenience and the integrated technology, effectively front-loading the cost you might otherwise spend on an extractor and other gear over time.

Equipment Flexibility

Langstroth hive components are standardized globally. You can buy boxes, frames, and other parts from any supplier, and they will almost always be compatible.

Flow Frames are a proprietary system. While they are designed to fit standard Langstroth-sized boxes, the frames themselves are a unique, non-interchangeable technology.

Maintenance and Cleaning

Traditional wooden frames and wax foundation are eventually cycled out and replaced. The storage of these items is part of the beekeeping cycle.

Flow Frames are a long-term investment that requires cleaning. While bees do much of the cleanup, a deep clean may be necessary, which presents a different kind of maintenance task compared to traditional equipment.

Making the Right Choice for Your Space

Ultimately, the decision depends on your personal goals, budget, and physical space constraints.

- If your primary focus is minimizing equipment footprint: The Flow Hive's all-in-one design is unmatched for beekeepers with limited storage, such as those in urban environments or with no garage.

- If your primary focus is budget and traditional practice: A Langstroth hive has a lower cost of entry and follows time-tested methods, but you must plan for future equipment purchases and storage space.

- If you value maximum convenience for harvesting: The Flow Hive offers the simplest, cleanest, and least labor-intensive harvesting method, which is a major factor for many hobbyists.

Choose the system that best aligns with your available space and how you wish to interact with your bees.

Summary Table:

| Equipment | Traditional Hive | Flow Hive |

|---|---|---|

| Honey Extractor | Required (Bulky) | Not Needed |

| Extra Honey Supers | Multiple Boxes to Store | Minimal to None |

| Processing Gear | Uncapping Knives, Filters, Buckets | Not Needed |

| Overall Storage Footprint | Large | Compact |

Ready to Simplify Your Apiary and Save on Storage Space?

As a commercial beekeeper or distributor, efficient use of space is critical to your operation's profitability. HONESTBEE supplies the high-quality, space-saving beekeeping equipment you need to streamline your workflow.

We help you:

- Reduce equipment overhead by sourcing innovative solutions like the Flow Hive.

- Maximize operational efficiency with gear designed for modern apiaries.

- Grow your business with reliable wholesale-focused supply chains.

Contact HONESTBEE today to discuss how our beekeeping supplies and equipment can optimize your storage and boost your bottom line.

Visual Guide

Related Products

- Professional Hive Top Bee Feeder for Beekeeping

- Premium Ventilated Goatskin Beekeeping Gloves with Full 3-Layer Mesh Sleeve

- Plastic Handle Single Row Artificial Fiber Bee Brush

- Professional Hive Front Entrance Bee Feeder

- Professional Engraved Round Hive Number Tags for Beekeeping

People Also Ask

- What is a top feeder for bees? Maximize Colony Health with Efficient Feeding

- What are the advantages of using top feeders for bees? Maximize Feeding Efficiency & Colony Safety

- What types of hive boxes is the round hive top feeder compatible with? Universal Fit for 8 & 10-Frame Langstroth Hives

- What is the best bee feeder for a hive? Choose the Right Feeder for Your Apiary's Scale

- What are the features of top feeders for bees? Maximize Hive Health with Safe, High-Capacity Feeding