At its core, a jar or bottle packing machine is an integrated system that automates the entire process of preparing a container for sale. It moves empty jars or bottles along a conveyor, fills them with a precise amount of product, secures them with a cap, and applies a label. This transforms a slow, labor-intensive task into a rapid and highly consistent production line.

The true purpose of a packing machine is not merely to fill bottles, but to achieve precision and speed at scale. It replaces manual variability with automated consistency, ensuring every product meets exact specifications for volume, safety, and appearance.

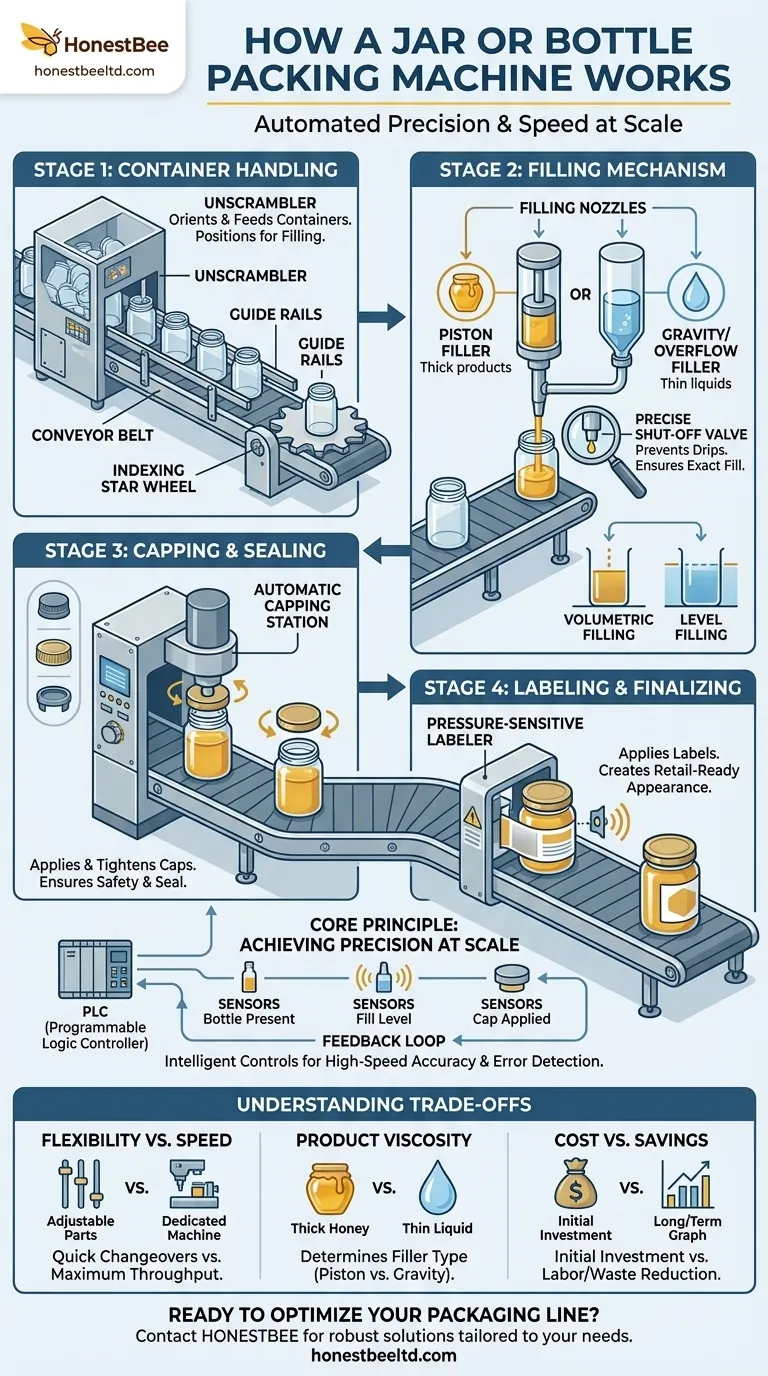

The Automated Packaging Workflow: A Step-by-Step Breakdown

A typical packing line operates as a sequential, multi-stage process. Each stage is designed to perform a specific task before handing the container off to the next station, all synchronized by a central control system.

Stage 1: Container Handling and Positioning

The process begins with getting empty containers onto the line and into the correct position. This is typically handled by an unscrambler, which orients and feeds bottles onto a conveyor belt.

The conveyor system is critical. It uses guide rails to keep containers stable and an indexing mechanism (like a star wheel or timing screw) to stop each one perfectly centered under the filling station.

Stage 2: The Filling Mechanism

This is the heart of the operation. Once a container is in position, filling nozzles descend and dispense the product. The key to accuracy is the filling technology used.

Common systems include piston fillers for thick products (like jams or sauces) and gravity or overflow fillers for thin liquids (like beverages or oils). Each nozzle is equipped with a precise shut-off valve to prevent drips and ensure the fill stops at the exact, predetermined value.

Stage 3: Capping and Sealing

Immediately after filling, the container moves to a capping station. This machine automatically places a cap onto the jar or bottle and tightens it to the correct torque.

This step is crucial for product safety, preventing leaks, and ensuring tamper evidence. Different cappers exist for various closure types, such as screw caps, snap-on lids, or press-on tops.

Stage 4: Labeling and Finalizing

The final automated step is labeling. The sealed containers pass through a labeler that applies a pressure-sensitive label to the body, neck, or cap.

Sensors detect the container's presence to ensure the label is applied smoothly and in the same location every time, giving the product its finished, retail-ready appearance.

The Core Principle: Achieving Precision at Scale

The value of a packing machine lies in its ability to repeat its function thousands of times without deviation. This reliability is achieved through a combination of mechanical design and intelligent controls.

The Role of Sensors and Controls

Modern packing lines are governed by a PLC (Programmable Logic Controller). This central computer receives input from sensors placed throughout the line.

These sensors detect if a bottle is present, if it's positioned correctly, if it's been filled, and if a cap has been applied. This feedback loop allows the machine to operate at high speed while instantly flagging errors like a missing container or a failed seal.

Achieving the "Predetermined Value"

The machine's ability to stop filling at a "predetermined value" is a core function. This is typically achieved in one of two ways:

- Volumetric Filling: A system like a piston filler dispenses an exact volume of product on each cycle. This is ideal for ensuring accurate net weight.

- Level Filling: An overflow filler fills each bottle to the same physical height. This provides a consistent appearance on the shelf, even if the internal volume of the bottles varies slightly.

The Importance of Shut-Off Valves

The reference to precise shut-off valves is critical. These components are what make clean, accurate filling possible at high speed.

When the target fill volume is reached, the valve closes instantly. This prevents post-fill dripping, which would waste product, create a mess, and result in inconsistent fill levels.

Understanding the Trade-offs

While highly efficient, these machines are not a one-size-fits-all solution. Choosing the right system involves balancing key priorities.

Flexibility vs. Speed

A machine dedicated to a single bottle size and product will always be faster than a flexible one. Lines designed for frequent changeovers to accommodate different container sizes require adjustable components, which adds complexity and setup time between runs.

Product Viscosity Matters

The type of filler is dictated entirely by the product. A gravity filler that works perfectly for water will fail completely with thick honey. The product's viscosity determines whether a pump, piston, gravity, or overflow system is required.

Initial Cost vs. Operational Savings

Automated packing lines represent a significant capital investment. This upfront cost must be weighed against the long-term savings from reduced labor, minimized product waste (giveaway), and increased production throughput.

Making the Right Choice for Your Goal

Selecting the correct packing machinery depends entirely on your specific production needs and business objectives.

- If your primary focus is a premium shelf appearance: A level or overflow filler is ideal, as it ensures all bottles look identically full.

- If your primary focus is precise dosing and minimizing product giveaway: A volumetric system, like a piston filler, is necessary to dispense the exact amount every time.

- If your primary focus is maximum throughput of one product: A dedicated rotary machine designed for a specific container will deliver the highest speeds.

- If your primary focus is producing a variety of products in different containers: An inline system with quick-change parts offers the flexibility you need.

Ultimately, understanding these core functions allows you to select a machine that serves as a cornerstone of your production efficiency and product quality.

Summary Table:

| Packaging Stage | Key Function | Technology Used |

|---|---|---|

| Container Handling | Orients and feeds empty containers | Unscrambler, Conveyor Belt |

| Filling | Dispenses precise product amount | Piston Filler, Gravity Filler, Overflow Filler |

| Capping & Sealing | Applies and tightens caps | Automatic Capping Machine |

| Labeling | Applies labels for retail-ready finish | Pressure-Sensitive Labeler |

Ready to optimize your packaging line with precision and speed? At HONESTBEE, we supply robust beekeeping supplies and equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get reliable, high-performance machinery tailored to your needs—whether you're filling honey, sauces, or other products. Contact us today to discuss how our solutions can enhance your production efficiency and product quality!

Visual Guide

Related Products

- Automatic In-Line Round Bottle Labeling Machine

- Semi Automatic Electric Bottle Capping Machine

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Automatic In-Line Flat Surface Labeling Machine

People Also Ask

- What technologies are incorporated into honey filling machines? Piston, Pump, or Gravity for Your Production

- What is the filling accuracy of the automatic dosing and bottling device? Boost Precision and Reduce Product Waste

- What equipment is used for bottling honey cleanly and efficiently? Professional Filling Solutions for Every Scale

- What role do industrial honey-filling machines play? Transform Your Apiary into a High-Efficiency Commercial Powerhouse

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export

- Why is professional honey filling and packaging equipment essential? Scale Your Commercial Honey Brand with Precision

- What are the benefits of using automated honey-filling machinery? Boost Efficiency and Value for Commercial Apiaries

- How does automated honey filling equipment contribute to international standards for honeydew honey exports?