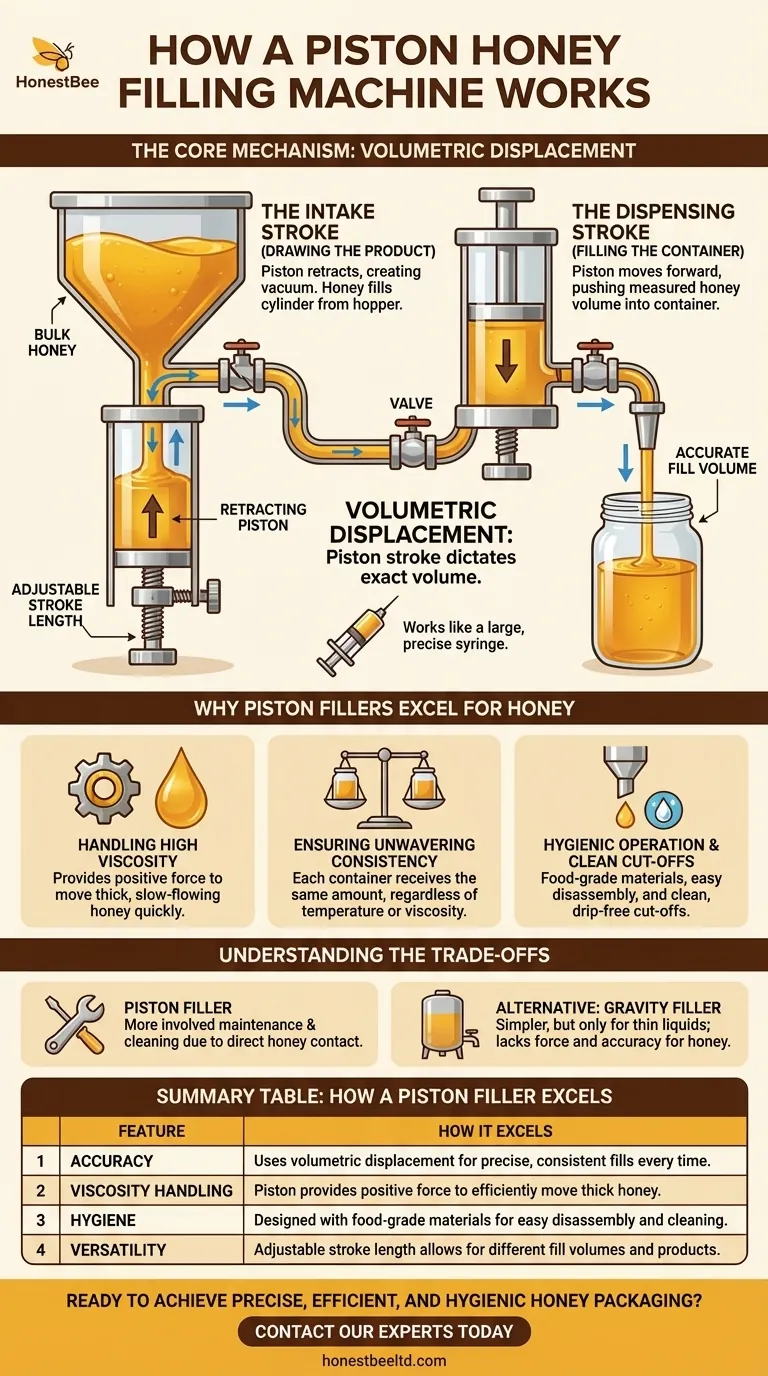

At its core, a piston honey filling machine works like a large, precise syringe. It uses a piston moving within a cylinder to pull a specific, measured volume of honey from a bulk container (a hopper) and then push that exact amount into a jar or bottle. This mechanical action provides the force needed to handle honey's high viscosity while ensuring each container is filled with exceptional accuracy.

The critical advantage of a piston filler is its principle of volumetric displacement. The machine doesn't guess or estimate; the physical volume of the cylinder, determined by the piston's stroke length, dictates the exact amount of honey dispensed in every single cycle.

The Core Mechanism: A Step-by-Step Breakdown

To understand why this method is so reliable for a thick product like honey, we can break down its operation into two primary movements.

The Intake Stroke (Drawing the Product)

The process begins with the piston retracting within its cylinder. This backward movement creates a vacuum.

Simultaneously, a valve opens a path between the main product hopper and the cylinder. The vacuum pulls the honey from the hopper, completely filling the cylinder.

The Dispensing Stroke (Filling the Container)

Once the cylinder is full, the valve system switches. The path to the hopper closes, and a new path to the filling nozzle opens.

The piston then moves forward, pushing the precisely measured volume of honey out of the cylinder, through the nozzle, and into the waiting container.

How Volume is Controlled

The key to the machine's accuracy is the adjustable stroke length of the piston.

A longer stroke pulls more honey into the cylinder, resulting in a larger fill volume. A shorter stroke results in a smaller fill. This mechanical setting is easy to adjust and highly repeatable.

Why Piston Fillers Excel for Honey

While other filling methods exist, the piston mechanism is uniquely suited for the challenges presented by honey.

Handling High Viscosity

Honey is thick and does not flow easily. A simple gravity-fed system would be slow and inconsistent. The piston provides the positive force required to move the honey quickly and predictably.

Ensuring Unwavering Consistency

The volumetric filling principle ensures that each container receives the same amount of product. This is crucial for maintaining product consistency and meeting label weight requirements, regardless of minor changes in honey temperature or viscosity.

Hygienic Operation and Clean Cut-Offs

Modern piston fillers are built with food-grade materials and designed for easy disassembly. This allows for thorough cleaning, which is essential for food safety.

The nozzle and valve system also provides a clean, drip-free cut-off after each fill, preventing product waste and messy containers.

Understanding the Trade-offs

While highly effective, it's important to recognize the operational considerations of a piston filler compared to other technologies.

Maintenance and Cleaning

Because the piston, cylinder, and valves are in direct contact with the honey, they must be meticulously cleaned. This process is more involved than cleaning a simpler system like a gravity filler, which has fewer moving parts.

The Alternative: Gravity Fillers

A gravity filler relies on the weight of the liquid in an overhead tank to fill containers. This design is simpler and often cheaper but is only suitable for thin, free-flowing liquids. For honey, it would lack the accuracy and force needed for an efficient operation.

Throughput and Scale

Piston fillers offer an excellent balance of speed and precision for small-to-medium-scale operations. For extremely high-speed, industrial-scale production, more complex and expensive rotary fillers might be used, but the piston filler remains the standard for most honey producers.

Making the Right Choice for Your Goal

The piston filler's design directly solves the core challenges of packaging a viscous product.

- If your primary focus is precision for a thick product like honey: The piston filler is the definitive choice for its unmatched volumetric accuracy.

- If your primary focus is operational hygiene: Prioritize piston fillers designed for quick, tool-less disassembly to simplify and speed up your cleaning protocols.

- If your primary focus is versatility: Piston fillers can handle a wide range of viscosities, from thin liquids to thick pastes, making them a flexible asset in a production line.

Ultimately, the piston filler's design provides the mechanical certainty required for packaging a challenging yet valuable product like honey.

Summary Table:

| Feature | How a Piston Filler Excels |

|---|---|

| Accuracy | Uses volumetric displacement for precise, consistent fills every time. |

| Viscosity Handling | Piston provides positive force to efficiently move thick honey. |

| Hygiene | Designed with food-grade materials for easy disassembly and cleaning. |

| Versatility | Adjustable stroke length allows for different fill volumes and products. |

Ready to achieve precise, efficient, and hygienic honey packaging?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused honey filling solutions. Our piston filling machines are engineered to handle the unique challenges of honey, ensuring accurate fills, minimal waste, and easy cleaning to protect your product quality.

Contact our experts today to find the perfect filling equipment to scale your operation and enhance your packaging line's performance.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How do honey filtration and filling machinery contribute to industrialization? Scale Your Commercial Honey Production

- What are the advantages of integrating professional-grade honey-filling machines? Scaling Your Production for Growth

- What are the primary functions and benefits of using a honey filling machine? Scale Your Production and Ensure Precision

- What options are available for filling containers with honey? Scale Your Beekeeping Business Efficiently

- How do industrial-grade honey filling machines preserve antioxidant activity? Expert Solutions for Apitherapy Products

- How does a honey weight calculator assist in the commercial honey bottling process? Optimize Your Production Yield

- What are the types of bottle filling machines? Find the Perfect Match for Your Product

- How do automated filling and packaging machines contribute to the market value of honey products? Boost Retail Profits