At its core, an electric honey extractor automates the process of harvesting honey by using an electric motor to spin honeycomb frames inside a large drum. This spinning action generates powerful centrifugal force, which flings the liquid honey out of the wax cells. The honey then runs down the interior walls of the drum and collects at the bottom, ready to be drained.

The fundamental value of an electric honey extractor is not just automation, but a dramatic increase in efficiency. It transforms honey harvesting from a physically demanding, time-consuming task into a rapid, streamlined process, making it an essential tool for any beekeeper managing more than a few hives.

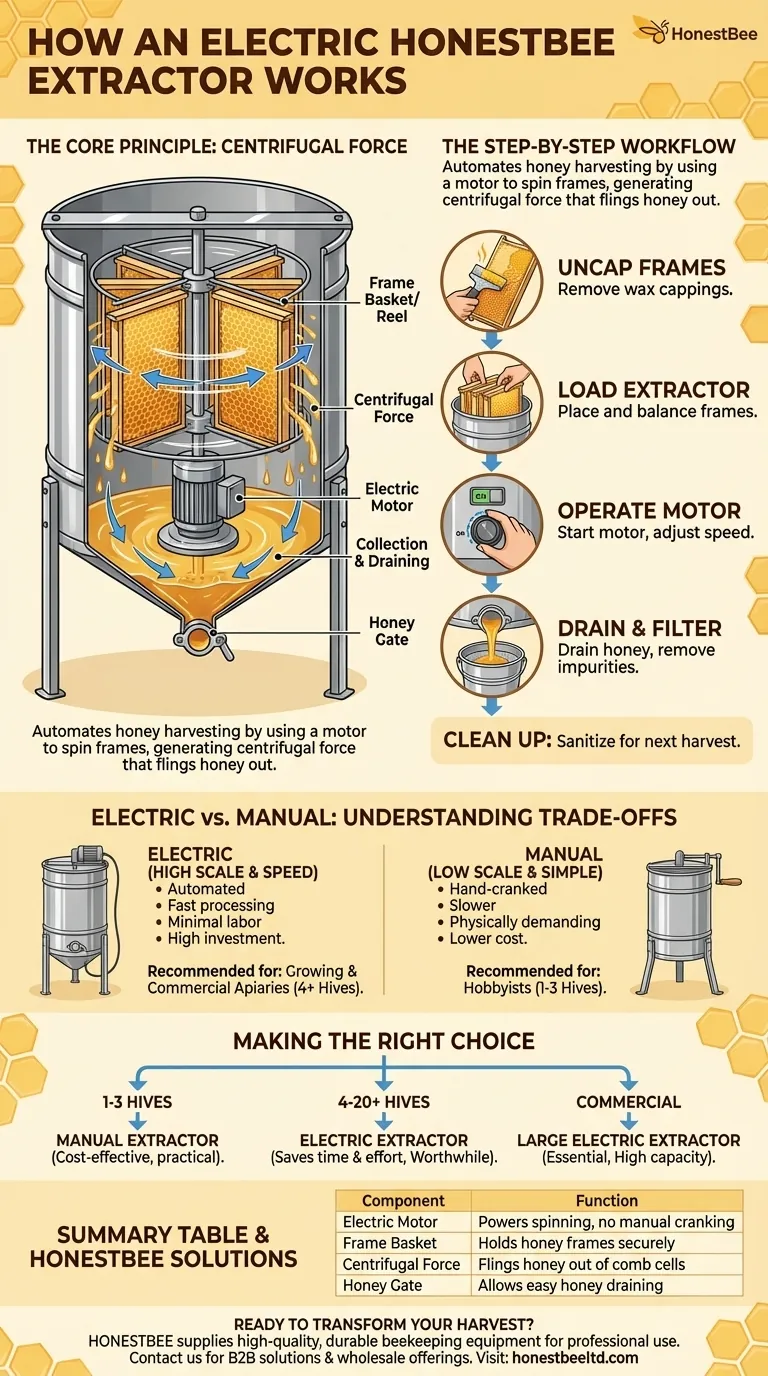

The Core Principle: Centrifugal Force at Work

An electric honey extractor operates on a simple, elegant principle of physics. The machine is an assembly of key parts designed to apply this force systematically.

The Electric Motor

The electric motor is the heart of the machine. Activated by a switch, it provides the power to rotate a central rod inside the drum at high speed, eliminating the need for manual cranking.

The Frame Basket (Reel)

Attached to this central rod is a basket, or reel, designed to hold several honey frames securely in place. Once the frames are loaded, the entire assembly spins as one unit.

The Spinning Process

As the motor spins the basket, it generates centrifugal force. This is the same outward-flinging force you feel on a fast-spinning carousel. This force pushes the honey out of the uncapped wax comb cells and against the inner wall of the extractor drum.

Collection and Draining

The extracted honey, now free from the comb, slides down the drum's walls by gravity. It pools at the bottom of the extractor, which is typically cone-shaped to facilitate draining through a tap or honey gate.

The Step-by-Step Extraction Workflow

Using an extractor is a key part of a larger honey harvesting process. The machine itself is just one step in the workflow.

Step 1: Uncapping the Frames

Before extraction, you must remove the beeswax cappings that seal the honey into the comb cells. This is typically done using a heated uncapping knife or a specialized fork to scrape the wax layer off.

Step 2: Loading the Extractor

The uncapped frames are then placed vertically into the slots of the extractor's basket. It's important to balance the load by placing frames of similar weight opposite each other to ensure smooth, stable spinning.

Step 3: Operating the Motor

With the lid secured, you simply turn on the motor. Many electric models have variable speed controls, allowing you to start slowly to avoid damaging the delicate comb and then ramp up the speed for maximum extraction.

Step 4: Draining and Filtering

Once the spinning is complete, the honey is drained through the honey gate at the bottom of the drum. It is typically passed through a series of filters or a sieve to remove any remaining bits of wax or other debris.

Step 5: Post-Extraction Cleanup

Thoroughly cleaning the extractor after use is critical. This prevents the spread of potential bee diseases and ensures your equipment is sanitary for the next harvest.

Understanding the Trade-offs: Electric vs. Manual

While the principle of centrifugal force is the same, the choice between an electric and manual extractor comes down to scale and effort.

The Case for Electric: Speed and Scale

An electric extractor is a game-changer for beekeepers with more than a couple of hives. It can process a high volume of frames quickly and with minimal physical labor, significantly reducing harvest time.

The Advantage of Manual: Cost and Simplicity

A manual extractor, operated with a hand crank, is a more affordable and simpler machine. For hobbyists with one or two hives, the lower cost and independence from a power source can make it a more practical choice.

The Primary Downside: Investment

The main drawback of an electric honey extractor is its higher initial cost. It is an investment in efficiency that pays off as the size of your beekeeping operation grows.

Making the Right Choice for Your Apiary

Selecting the right tool depends entirely on the scale of your beekeeping and your long-term goals.

- If your primary focus is a small hobby with 1-3 hives: A manual extractor is often the most cost-effective and practical solution.

- If your primary focus is managing a growing apiary of 4-20+ hives: An electric extractor will save you a significant amount of time and physical effort, making it a worthwhile investment.

- If your primary focus is semi-commercial or commercial beekeeping: A large, high-capacity electric extractor is an essential piece of equipment for processing honey efficiently.

Ultimately, choosing the right extractor is about matching the tool's power and capacity to the demands of your harvest.

Summary Table:

| Component | Function |

|---|---|

| Electric Motor | Powers the spinning, eliminating manual cranking. |

| Frame Basket | Holds honey frames securely during the spin cycle. |

| Centrifugal Force | Flings honey out of the uncapped wax comb cells. |

| Honey Gate | Allows for easy draining of the extracted honey. |

Ready to transform your honey harvest?

An electric honey extractor is a vital investment for commercial apiaries and distributors looking to scale their operations efficiently. HONESTBEE supplies high-quality, durable beekeeping equipment designed for high-volume, professional use.

Contact our expert team today to discuss the best extraction solutions for your business and learn about our wholesale-focused offerings.

Visual Guide

Related Products

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How do weighing methods and mechanical honey extraction equipment assist in evaluating yield impact? Optimize Production

- What role does the Stainless Steel Centrifugal Honey Extractor play? Maximize Yield and Purity in Your Apiary

- How long does it take to extract honey from frames? Plan Your Harvest Efficiently

- How do industrial-grade honey extractors ensure efficiency? Boost Your Harvest While Protecting Colony Health

- What are the three methods of extracting honey? Choose the Right Technique for Your Apiary

- What are the advantages of motorized extractors? Boost Honey Production and Save Time

- How does a mechanized honey extractor function? Boost Your Harvest with Centrifugal Technology

- What equipment is typically used for honey extraction? Professional Tools for High-Yield Harvesting