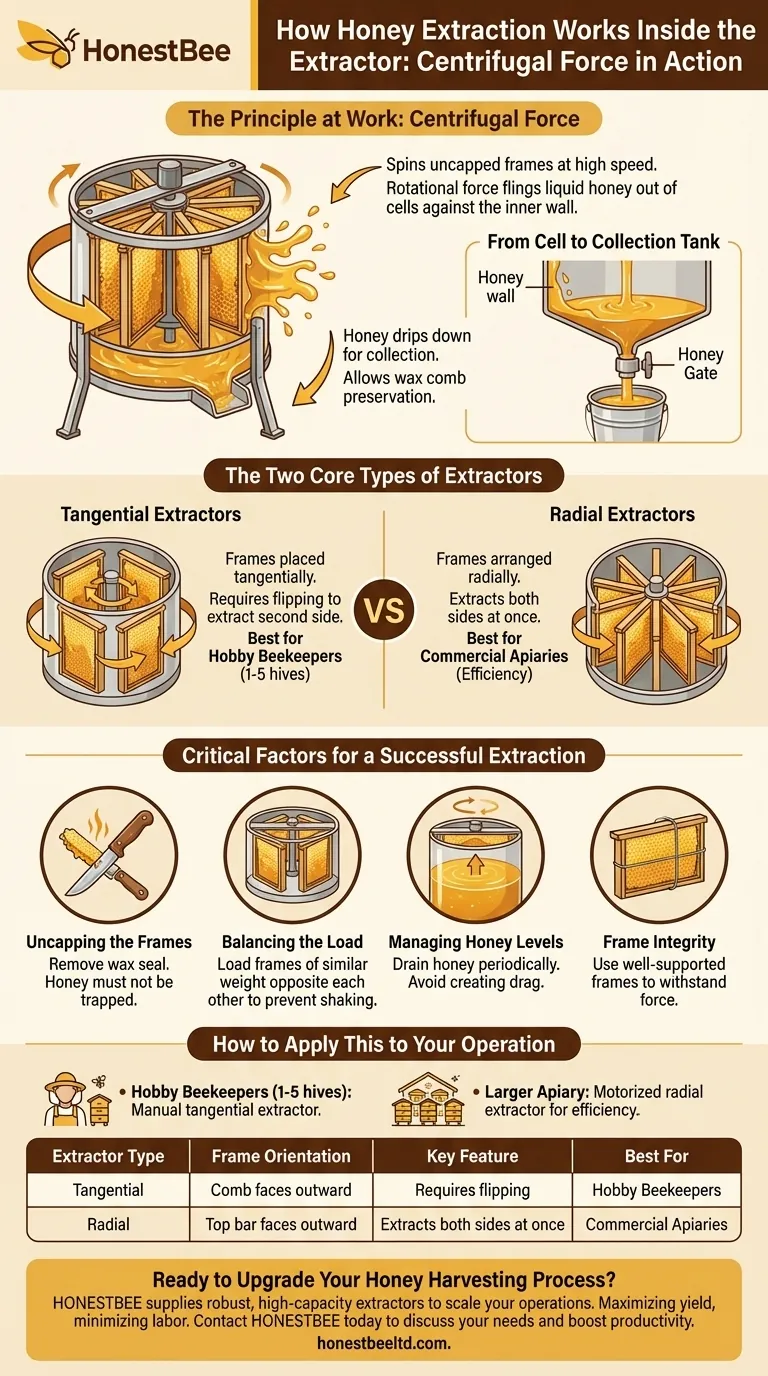

At its core, a honey extractor works by using centrifugal force. It spins uncapped honey frames at a high speed inside a large drum. This rotational force flings the liquid honey out of the wax honeycomb cells and against the inner wall of the extractor, where it drips down to be collected at the bottom.

The entire process is a mechanical method for separating honey from the comb efficiently and cleanly. By using rotational force, it allows beekeepers to harvest the honey while preserving the delicate wax comb for the bees to reuse.

The Principle at Work: Centrifugal Force

How Centrifugal Force Extracts Honey

Centrifugal force is the outward force experienced by an object moving in a circle. Think of swinging a bucket of water around your head; the force pins the water to the bottom of the bucket, preventing it from spilling.

A honey extractor applies this same principle to honeycombs. As the frames spin, the honey inside the cells is pushed outwards, away from the center of rotation. This force overcomes the honey's natural thickness (viscosity) and the surface tension holding it in the wax cell, causing it to fly out.

From Cell to Collection Tank

Once flung from the comb, the honey strikes the interior wall of the extractor drum. Gravity then takes over, and the honey runs down the smooth walls, pooling at the conical bottom of the tank. A small tap or valve, often called a honey gate, allows the collected honey to be drained into buckets or other containers.

The Two Core Types of Extractors

The way frames are positioned inside the extractor determines its type and how it's operated.

Tangential Extractors

In a tangential extractor, the frames are placed so the surface of the honeycomb faces outward, tangential to the wall of the drum. This design focuses the centrifugal force directly on one side of the comb at a time.

Because of this, you must extract the honey in two stages. First, you spin out a portion of the honey from one side, then you must physically stop, flip the frames around, and spin again to extract from the other side.

Radial Extractors

In a radial extractor, the frames are arranged like the spokes of a wheel, with the top bar of the frame facing outward. As it spins, honey is thrown from both sides of the comb simultaneously.

This design is significantly more efficient for larger operations as it eliminates the need to flip the frames, saving considerable time and labor.

Critical Factors for a Successful Extraction

Simply spinning the frames is not enough. Several factors are crucial for preventing damage to your equipment, your frames, and your honey.

Uncapping the Frames

Before any honey can be extracted, the wax seal on each cell must be removed. This is done with a heated knife or a specialized uncapping fork. If the wax cappings are not removed, the honey will remain trapped in the cells no matter how fast you spin the extractor.

Balancing the Load

This is arguably the most critical step. You must load the extractor with frames of similar weight positioned opposite each other. An unbalanced load will cause the extractor to shake violently, potentially damaging the machine, the frames, and creating a safety hazard.

Managing Honey Levels

As honey collects at the bottom, its level will rise. If the honey level rises high enough to touch the bottom of the spinning frames, it will create significant drag. This prevents the extractor from reaching the necessary speed to effectively remove the remaining honey. It's essential to drain the honey periodically during the process.

Frame Integrity

The immense force generated during extraction can be destructive. Frames that are old, poorly built, or lack wire or plastic foundation for support can disintegrate during the spin. Always use well-supported frames to ensure the comb can withstand the process.

How to Apply This to Your Operation

Choosing the right equipment and process depends entirely on the scale of your beekeeping.

- If your primary focus is hobby beekeeping (1-5 hives): A smaller, manual tangential extractor is often the most practical and cost-effective choice.

- If your primary focus is efficiency for a larger apiary: A motorized radial extractor is a necessary investment to process a large number of frames quickly.

Understanding these mechanics ensures you can extract your honey efficiently while preserving the vital comb structure for your bees.

Summary Table:

| Extractor Type | Frame Orientation | Key Feature | Best For |

|---|---|---|---|

| Tangential | Comb faces outward | Requires flipping frames | Hobby Beekeepers (1-5 hives) |

| Radial | Top bar faces outward | Extracts both sides at once | Commercial Apiaries (Efficiency) |

Ready to Upgrade Your Honey Harvesting Process?

As a commercial apiary or beekeeping equipment distributor, your efficiency is paramount. HONESTBEE supplies the robust, high-capacity extractors and professional beekeeping equipment you need to scale your operations. Our wholesale-focused solutions are designed to maximize your yield and minimize labor.

Contact HONESTBEE today to discuss your specific needs and discover how our equipment can boost your productivity.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What should be considered when using a honey extractor to avoid damage? Ensure a Smooth, Efficient Harvest

- What is the purpose of decanting in honey extraction? Achieve a Purer, More Stable Honey Product

- What are the benefits of using a honey extractor? Maximize Harvest & Save Bee Energy

- What equipment is used for honey harvest? Essential Tools for Every Beekeeper

- How long should you spin honey? Master the Art of Efficient, Damage-Free Extraction