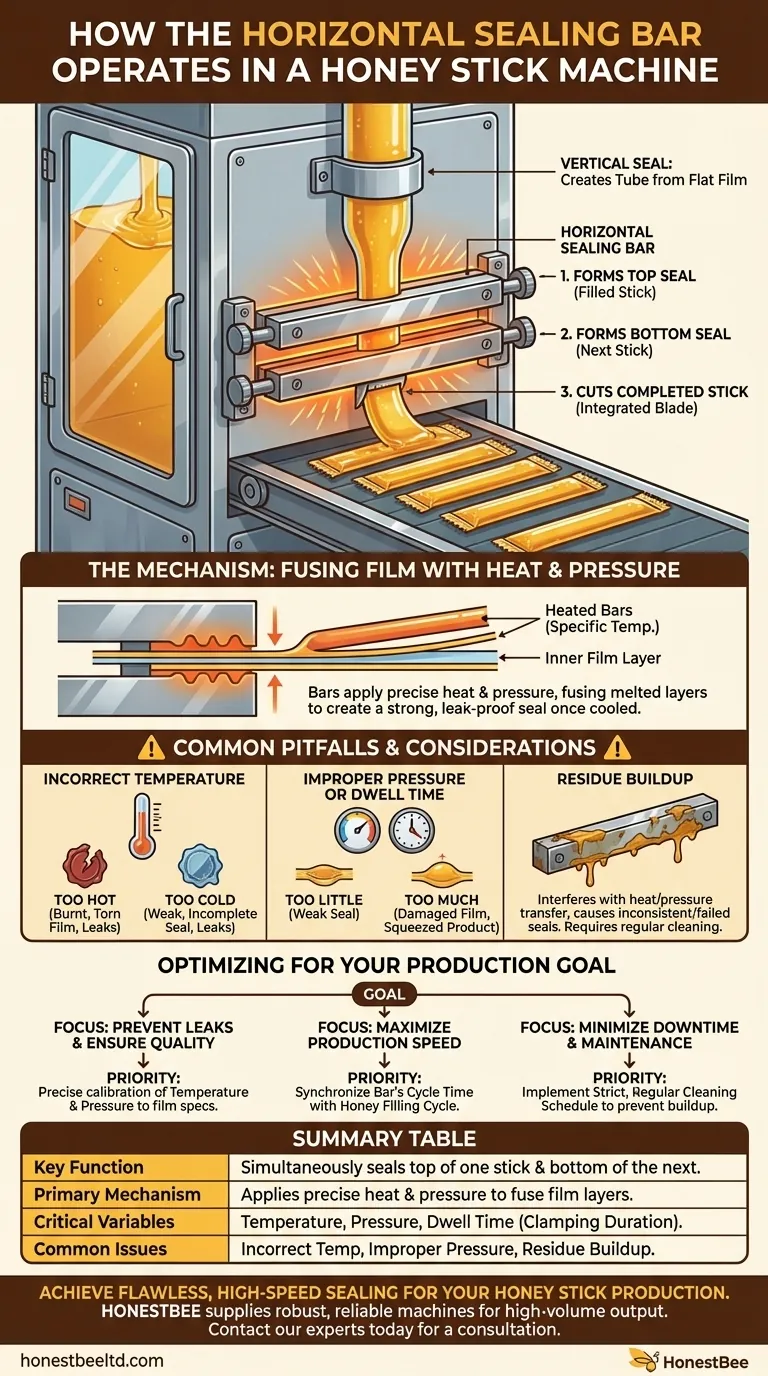

In essence, the horizontal sealing bar creates the top and bottom seals of the honey stick. After the packaging film has been formed into a tube and filled with honey, this bar clamps down, using heat and pressure to simultaneously seal the top of the filled stick and the bottom of the next one in the continuous tube.

The horizontal sealing bar is the final, critical step in creating an individual honey stick. It transforms a continuous, honey-filled tube into distinct, sealed units by applying precise heat and pressure to create the transverse seals.

How Sealing Creates the Final Product

To understand the horizontal sealing bar's function, it's best to see it as part of a synchronized sealing process. It works in tandem with a vertical sealing component to create a completely enclosed package.

The First Step: Creating the Tube

Before the horizontal bar can act, a vertical sealing bar creates the initial shape. It takes the flat packaging film, wraps it into a cylinder, and seals the two long edges together.

This process creates a long, continuous tube, which is the foundational structure for the honey sticks.

The Second Step: Forming, Filling, and Sealing

With the tube formed, the horizontal sealing bar performs its multi-part function. It moves in to clamp the film tube at a specific interval.

This single clamping action accomplishes three things at once:

- Forms the top seal of the stick that has just been filled with honey.

- Forms the bottom seal of the next stick to be filled.

- Cuts the completed stick free from the continuous film (most bars include an integrated slicing blade).

The Mechanism: Fusing Film with Heat and Pressure

The principle behind the seal is simple but precise. The bar heats up to a specific temperature designed to melt the inner layer of the packaging film.

When the bar clamps down, it applies firm pressure, fusing the melted layers of film together. Once cooled, this creates a strong, leak-proof seal that contains the honey.

Common Pitfalls and Considerations

Achieving a perfect seal every time requires careful calibration. The horizontal sealing process is sensitive to several variables that can impact product quality and lead to waste.

Incorrect Temperature Settings

The most common issue is improper temperature. If the bar is too hot, it can burn or weaken the packaging film, causing it to tear.

If it is too cold, the film won't melt sufficiently, resulting in a weak or incomplete seal that will leak.

Improper Pressure or Dwell Time

The amount of pressure and the duration the bar stays clamped (the dwell time) are just as important as temperature.

Too little pressure or time will create a weak seal. Too much can damage the film or squeeze the product out into the seal area, compromising its integrity.

Residue Buildup

Over time, small amounts of honey or film residue can build up on the sealing bar's surface.

This buildup can interfere with heat transfer and pressure distribution, leading to inconsistent or failed seals. Regular cleaning and maintenance are essential for reliable operation.

Optimizing for Your Production Goal

Calibrating the horizontal sealing bar correctly depends entirely on your operational priorities.

- If your primary focus is preventing leaks and ensuring product quality: Prioritize the precise calibration of temperature and pressure to match the specifications of your packaging film.

- If your primary focus is maximizing production speed: Ensure the bar's cycle time (clamping, sealing, and releasing) is perfectly synchronized with the honey filling cycle to avoid bottlenecks.

- If your primary focus is minimizing downtime and maintenance: Implement a strict, regular cleaning schedule for the sealing bar to prevent residue buildup and ensure consistent performance.

Ultimately, mastering the function of the horizontal sealing bar is fundamental to achieving a reliable and efficient honey stick production line.

Summary Table:

| Key Function | Description |

|---|---|

| Sealing Action | Simultaneously seals the top of one stick and the bottom of the next. |

| Primary Mechanism | Applies precise heat and pressure to fuse packaging film layers. |

| Critical Variables | Temperature, pressure, and dwell time (clamping duration). |

| Common Issues | Incorrect temperature, improper pressure, and residue buildup on the bar. |

Achieve flawless, high-speed sealing for your honey stick production. The horizontal sealing bar is a critical component for product integrity and line efficiency. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, reliable honey stick machines and sealing components designed for high-volume output. Our wholesale-focused operations ensure you get the durable equipment you need to minimize downtime and maximize quality. Let's optimize your packaging line—contact our experts today for a consultation.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- Why is automated packaging machinery essential for scaling industrial honey production? Drive Commercial Scalability

- How do automatic capsule filling machines ensure royal jelly quality? Precision Systems for Large-Scale Packaging

- Can honey filling machines be used to fill cosmetic products? Maximize Your Filling Line's Versatility

- How do automated filling and labeling systems ensure EU compliance? Master Honey Regulations with Precision Technology

- How does production volume influence the choice of a honey packaging machine? Scale Your Operation Efficiently

- What is the commercial value of automatic honey filling equipment and beehive machinery? Scale Your Apiary Business

- What is the function of a twin honey stick machine? Double Your Honey Stick Production

- What advantages does specialized honey filling machinery offer? Scale Your Production with Automated Precision