At its core, the difference in inspection processes between Langstroth and top bar hives stems from their fundamental design philosophies. A Langstroth hive inspection is a modular, systematic process involving the disassembly of boxes and the examination of individual, reinforced frames. In contrast, a top bar hive inspection is a less disruptive, sequential process of examining one natural, fragile comb at a time along the length of a single box.

The choice between these hives is a choice between two distinct management philosophies. Langstroth hives are built for granular control and intervention to maximize production, while top bar hives are designed for a less intrusive, more holistic approach that mimics the bees' natural behavior. Your preferred inspection process will reveal your preferred beekeeping style.

The Core Difference: Frame vs. Bar

The most significant distinction lies in how the comb is structured and accessed. This dictates every aspect of the inspection, from the tools you use to the way you handle the components.

Langstroth: The Modular Approach

A Langstroth hive is a vertical stack of boxes, each containing 8 to 10 removable frames. These frames provide full, four-sided support for the comb.

Inspections require you to disassemble this stack. You work your way down, box by box, lifting off heavy supers to access the brood chambers below. Each frame can be pulled out, turned, and examined individually for brood patterns, pests like varroa mites, and honey stores.

Top Bar: The Sequential Approach

A top bar hive is a single, long horizontal box with a series of simple wooden bars laid across the top. Bees build their comb naturally, drawing it down from a starter strip on each bar.

An inspection begins at one end of the hive. You remove one bar at a time, carefully inspecting the attached comb before placing it back and moving to the next. Only a small portion of the colony is exposed at any given moment.

How Structure Impacts the Inspection Workflow

The physical design of each hive creates profoundly different experiences and requirements for the beekeeper during an inspection.

Disruption and Exposure

Langstroth inspections are inherently more disruptive. Removing an entire box exposes a large surface area of the colony to open air and light, which can be stressful for the bees.

Top bar inspections are gentler. By moving one bar at a time, you keep the vast majority of the colony covered and calm, reducing overall stress. Many top bar hives feature hinged roofs, which makes opening the hive and managing the bars even easier.

Comb Handling and Fragility

Langstroth frames are robust. The comb is supported and reinforced, allowing you to handle frames with confidence.

Top bar combs are extremely fragile, attached only to the top bar. You must handle them with immense care, always keeping the comb in a vertical position. Tilting it horizontally will cause the delicate, wax-heavy comb to break off the bar.

Finding the Queen

In a Langstroth system, beekeepers often use a queen excluder. This grid prevents the larger queen from moving into the honey supers, confining her to the lower brood boxes and making her location more predictable.

In a top bar hive, the queen has the freedom to roam the entire length of the hive. This allows for more natural colony behavior but can make locating her during an inspection a more time-consuming task.

Understanding the Trade-offs

Neither inspection method is universally "better"; they are simply different tools for different goals, and each comes with trade-offs.

Control vs. Natural Behavior

The Langstroth system offers unparalleled control. You can easily move frames of brood, honey, or eggs between hives, reconfigure the nest, and manage space to maximize honey production.

The top bar system prioritizes a more hands-off, natural approach. The design encourages the beekeeper to be an observer first and an interventionist second, respecting the bees' tendency to build comb as they would in the wild.

Honey and Wax Yield

The Langstroth inspection and harvest process is designed to preserve comb. Honey is extracted using a centrifuge, leaving the valuable drawn comb intact. Bees can immediately refill it, which is why Langstroth hives produce significantly more honey (5-10 gallons annually).

Harvesting from a top bar hive requires cutting the entire comb off the bar. The honey is then separated by crushing the comb and straining it. This process destroys the comb, forcing the bees to expend energy rebuilding it and resulting in lower honey yields (3-5 gallons annually). However, it produces a much larger quantity of clean beeswax.

Physical Effort and Equipment

Inspecting a Langstroth hive requires heavy lifting, as honey supers can weigh 50 pounds or more. Harvesting also requires specialized and expensive equipment like extractors and uncapping knives.

Top bar hives involve no heavy lifting of boxes. The bars themselves are light, making inspections physically accessible to more people. The "crush and strain" harvest method requires only simple household utensils.

Choosing the Hive That Fits Your Beekeeping Goal

Your decision should be based on what you want to achieve as a beekeeper and how you wish to interact with your bees.

- If your primary focus is maximizing honey production and granular control: The Langstroth hive is the superior choice, as its modular frame system is engineered for efficiency and intervention.

- If your primary focus is a "natural," less intrusive experience with minimal heavy lifting: The top bar hive is ideal, as its design encourages gentler, less frequent inspections.

- If your primary focus is harvesting beeswax in addition to honey: The top bar hive's "crush and strain" method will provide a significantly larger and more valuable wax harvest.

Ultimately, understanding these inspection differences allows you to choose the hive that aligns with your goals and your desired relationship with your bees.

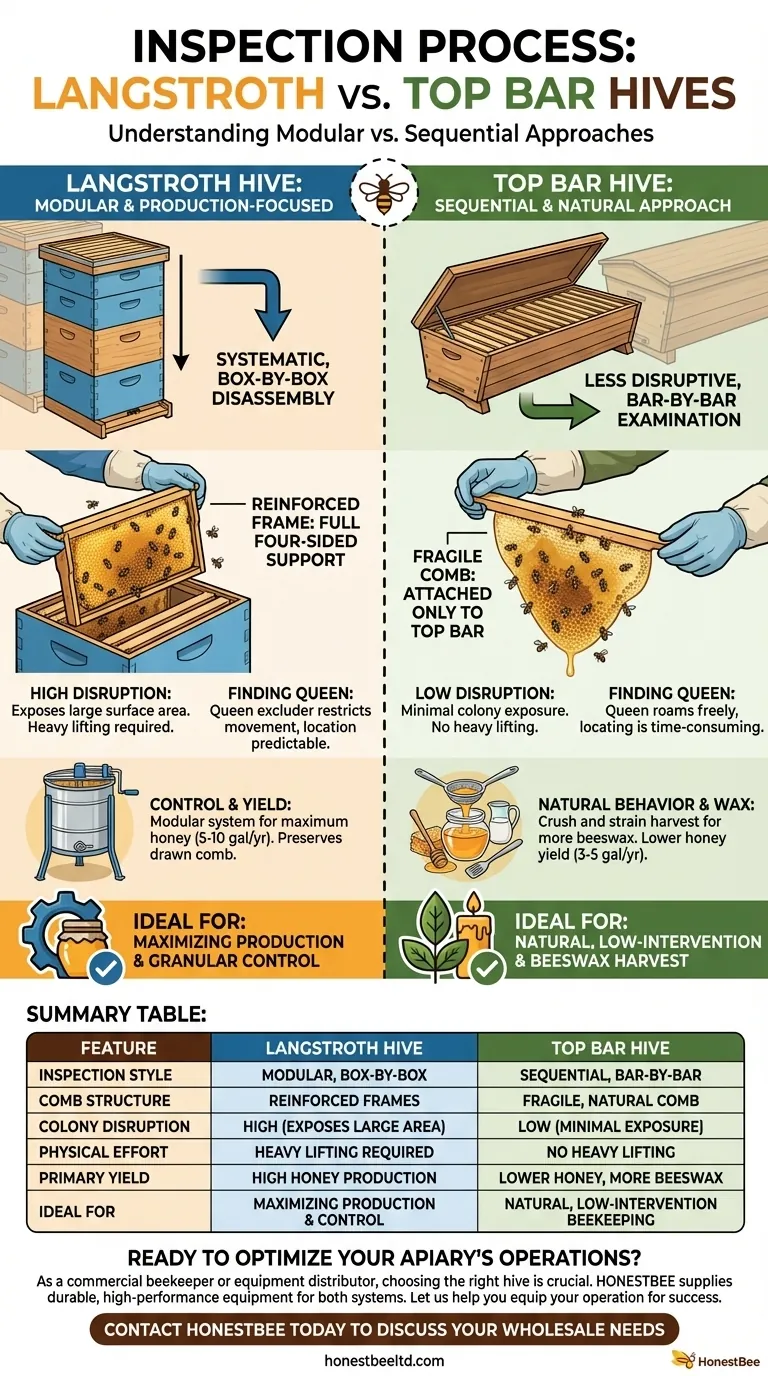

Summary Table:

| Feature | Langstroth Hive | Top Bar Hive |

|---|---|---|

| Inspection Style | Modular, box-by-box | Sequential, bar-by-bar |

| Comb Structure | Reinforced frames | Fragile, natural comb |

| Colony Disruption | High (exposes large area) | Low (minimal exposure) |

| Physical Effort | Heavy lifting required | No heavy lifting |

| Primary Yield | High honey production | Lower honey, more beeswax |

| Ideal For | Maximizing production & control | Natural, low-intervention beekeeping |

Ready to Optimize Your Apiary's Operations?

As a commercial beekeeper or equipment distributor, choosing the right hive is crucial for efficiency and yield. At HONESTBEE, we supply the durable, high-performance equipment you need to succeed, whether you manage Langstroth hives for maximum honey production or prefer the natural approach of top bar systems.

Let us help you equip your operation for success. Contact HONESTBEE today to discuss your wholesale needs and discover how our beekeeping supplies can enhance your productivity and profitability.

Visual Guide

Related Products

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Plastic Bee Hive Stand for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What are the standard sizes for Langstroth hive boxes? Choose the Right Fit for Your Apiary

- How do Screened Bottom Boards facilitate the monitoring of Varroa mite natural mortality? Accurate Pest Monitoring Tips

- How many boxes do you need for a hive? Optimize Your Hive for Health and Honey Production

- What is the recommended starting configuration for a Langstroth hive? Choose the Right Setup for Your Apiary

- What are the benefits of the standardization of Langstroth beehive components for commercial beekeepers? Scale Fast

- What is the core function of Modern Frame Hives? Boost Your Large-Scale Honey Production Efficiency

- What is the step-by-step process for adding a super to a beehive? Master Hive Expansion for Maximum Honey Production

- What role do Langstroth bee hives play in making beekeeping more accessible? Empowering Diverse Groups in Apiculture