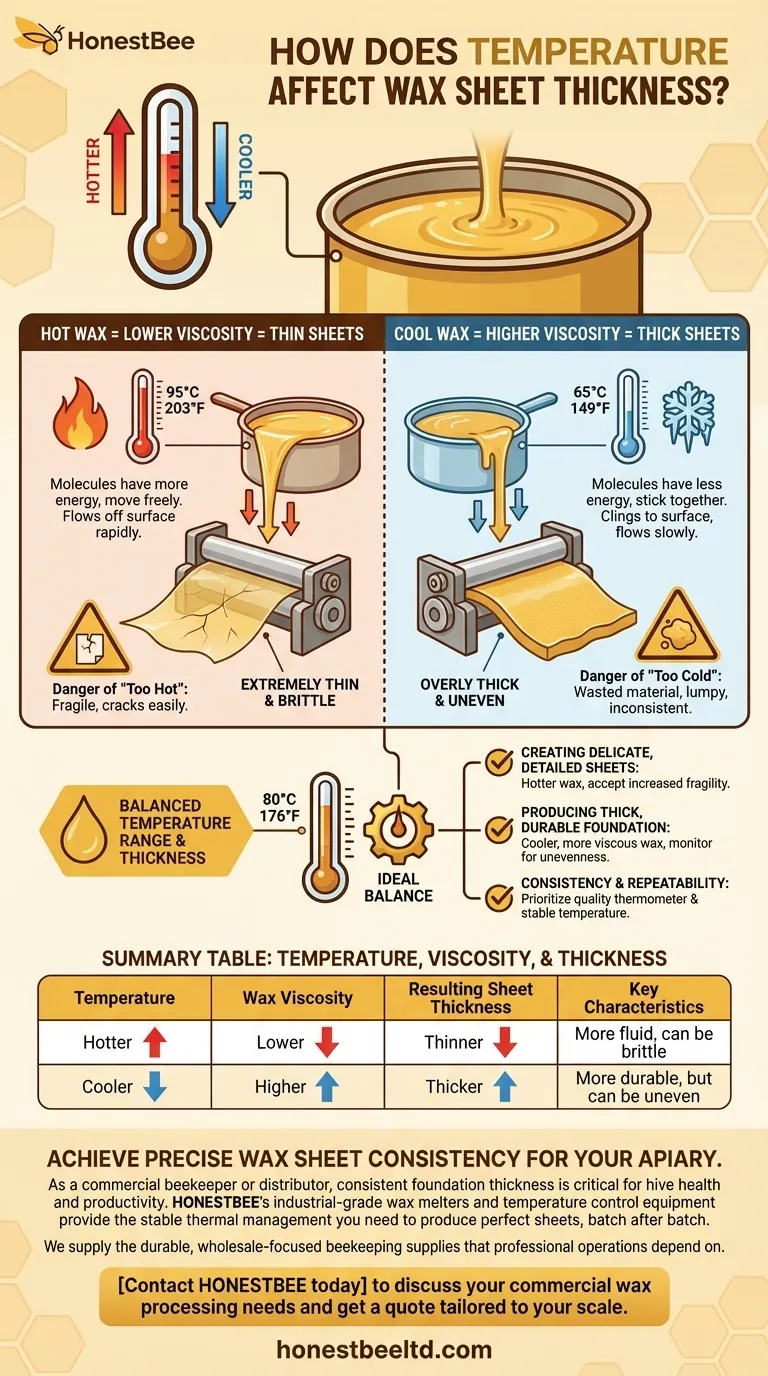

The relationship is direct and inverse. The temperature of the liquid wax is the primary factor controlling the thickness of the final sheets. Hotter wax produces thinner sheets, while cooler wax produces thicker sheets. This is because temperature directly governs the wax's viscosity, or its resistance to flow.

Controlling wax sheet thickness is a matter of managing temperature. The hotter the wax, the lower its viscosity and the thinner the resulting sheet; the colder the wax, the higher its viscosity and the thicker the sheet.

The Core Principle: Temperature and Viscosity

To achieve consistent results, you must understand not just what happens, but why it happens. The key principle at work is viscosity.

How Heat Reduces Viscosity

When you heat wax, you are giving its molecules more energy. This increased energy allows them to move past one another more freely and quickly.

Think of honey or syrup. When cold, it's thick and sluggish. When warmed, it becomes runny and flows easily. Liquid wax behaves in precisely the same way.

The Effect on Sheet Formation

When you dip a board or run wax through a roller, a low-viscosity (hot) wax will flow off the surface rapidly, leaving only a thin film behind before it cools and solidifies.

How Cold Increases Viscosity

Conversely, cooler wax has less thermal energy. Its molecules are slower and "stick" together more, creating a higher resistance to flow.

This makes the wax thick, dense, and sluggish. It does not move as easily.

The Effect on Sheet Formation

A high-viscosity (cool) wax clings to the surface. It flows off very slowly, allowing a much thicker layer to build up before it has a chance to run off.

Understanding the Pitfalls: Working at the Extremes

Finding the right temperature is a balancing act. Going too far in either direction will create problems.

The Danger of "Too Hot"

If the wax is excessively hot, the resulting sheets will be extremely thin and brittle.

They may be too fragile for their intended use, such as a beeswax foundation that can't support the weight of the colony, and can easily crack or tear during handling.

The Danger of "Too Cold"

If the wax is too cold, the sheets will be overly thick and uneven.

You will waste material, and the final sheets may be lumpy or have an inconsistent texture. In applications like beekeeping, sheets that are too thick may not fit properly into the hive frames.

Making the Right Choice for Your Goal

Your ideal temperature depends entirely on your project's specific needs. Use these principles to guide your adjustments.

- If your primary focus is creating delicate, detailed sheets: You will need to work with hotter wax, but be prepared for the trade-off of increased fragility.

- If your primary focus is producing thick, durable foundation: You should use cooler, more viscous wax, while carefully monitoring for lumpiness or unevenness.

- If your primary focus is consistency and repeatability: You must prioritize using a quality thermometer and maintaining a stable wax temperature throughout your entire process.

Mastering this principle transforms wax work from a guessing game into a controlled craft.

Summary Table:

| Temperature | Wax Viscosity | Resulting Sheet Thickness | Key Characteristics |

|---|---|---|---|

| Hotter | Lower | Thinner | More fluid, can be brittle |

| Cooler | Higher | Thicker | More durable, but can be uneven |

Achieve precise wax sheet consistency for your apiary.

As a commercial beekeeper or equipment distributor, consistent foundation thickness is critical for hive health and productivity. HONESTBEE's industrial-grade wax melters and temperature control equipment provide the stable thermal management you need to produce perfect sheets, batch after batch.

We supply the durable, wholesale-focused beekeeping supplies that professional operations depend on.

Contact HONESTBEE today to discuss your commercial wax processing needs and get a quote tailored to your scale.

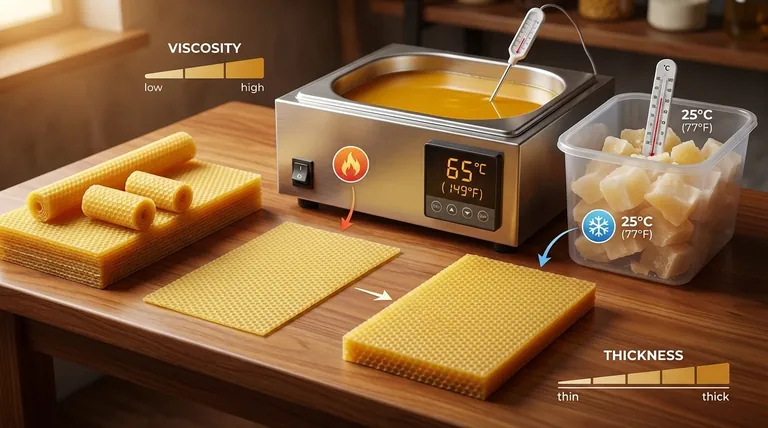

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What are the advantages of using beeswax foundation in a beehive? Boost Honey Yields and Hive Purity

- Why is beeswax foundation considered an essential consumable? Maximize Hive Productivity and Honey Yields

- Why are beeswax foundations critical for honey yield? Boost Your Commercial Apiary's Production Efficiency Today

- How should wax foundation sheets be maintained and cared for? Essential Tips for Storage and Hygiene

- What are the pros and cons of pure beeswax foundation? Optimize Your Hive Health & Comb Production