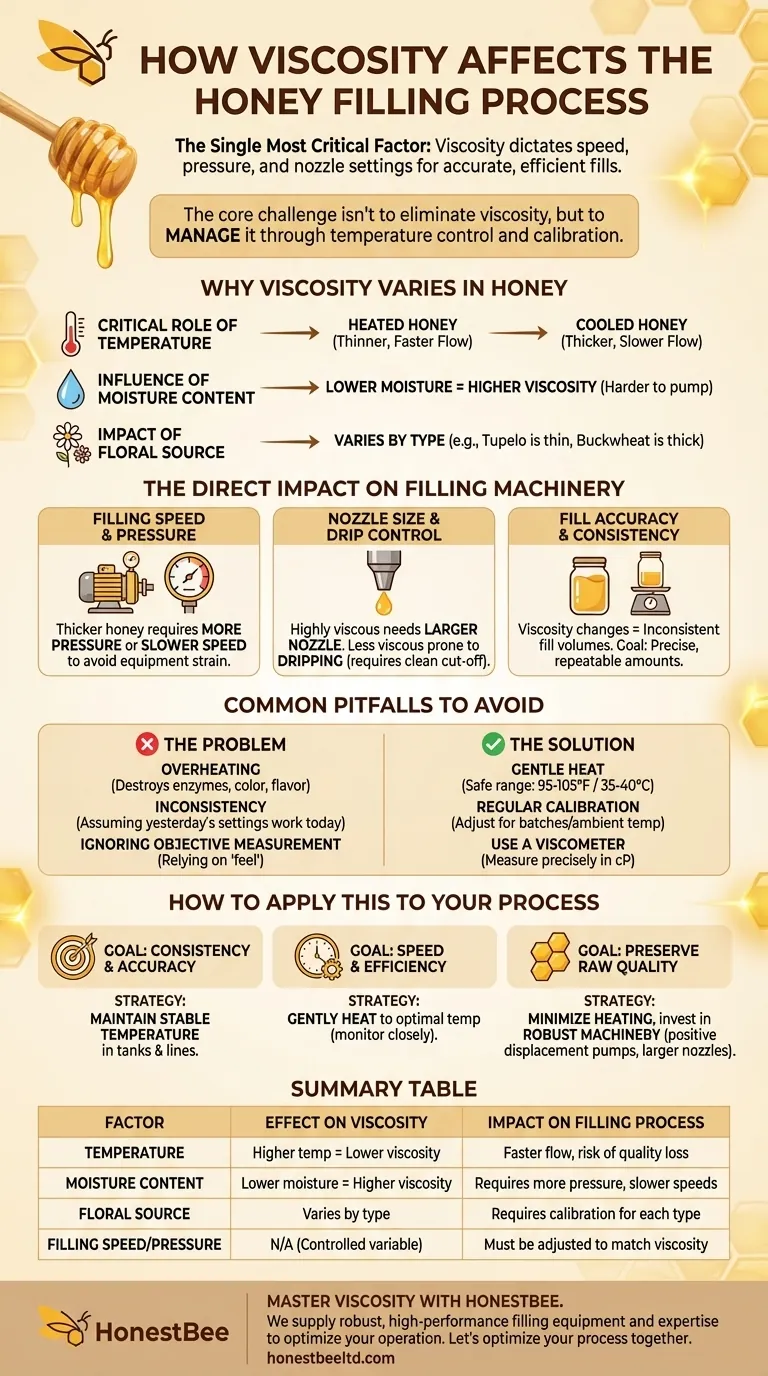

In short, viscosity is the single most critical factor governing the honey filling process. As a honey's thickness (viscosity) changes with temperature and composition, it directly dictates the required speed, pressure, and nozzle settings of your filling equipment to ensure each jar is filled accurately and efficiently without damaging the product.

The core challenge isn't to eliminate viscosity, but to manage it. By controlling honey's temperature and calibrating your machinery accordingly, you can achieve a consistent, repeatable, and high-quality filling operation.

Why Viscosity Varies in Honey

To control the filling process, you must first understand why honey's viscosity is not a fixed property. It is a dynamic variable influenced by several key factors.

Defining Viscosity in Simple Terms

Viscosity is a fluid's resistance to flow. Think of the difference between pouring water (low viscosity) and molasses (high viscosity). Honey's high sugar concentration and low moisture content make it naturally viscous.

The Critical Role of Temperature

Temperature is the primary lever you can pull to manage viscosity. When honey is heated, it becomes thinner and flows more easily, lowering its viscosity. Conversely, as it cools, it becomes thicker and more resistant to flow.

The Influence of Moisture Content

The amount of water in honey also affects its thickness. Honey with a lower moisture content is typically of higher quality but is also more viscous and harder to pump and fill.

The Impact of Floral Source

Different types of honey have inherently different viscosities. For example, Tupelo honey is naturally thin, while Buckwheat honey is much thicker, even at the same temperature.

The Direct Impact on Filling Machinery

Changes in viscosity have a direct and immediate effect on the performance and settings of your filling equipment. Failing to adjust for these changes leads to inefficiency and inconsistency.

Filling Speed and Pressure

Thicker, more viscous honey requires more pressure or a slower filling speed to move through pumps and tubing. Attempting to force highly viscous honey through at high speeds can strain or damage your equipment.

Nozzle Size and Drip Control

Highly viscous honey may require a larger nozzle to flow properly without excessive back-pressure. Less viscous (warmer) honey flows faster but is prone to dripping or stringing after the fill is complete, requiring a clean cut-off mechanism to avoid messy containers.

Fill Accuracy and Consistency

The ultimate goal is for every jar to contain the same amount of product. If the honey's viscosity changes during a production run (e.g., due to temperature fluctuations), the fill volume will become inconsistent, leading to under-filled or over-filled jars.

Common Pitfalls to Avoid

Managing viscosity involves a delicate balance. Simply heating the honey to make it flow is not always the best solution and can introduce new problems.

The Problem with Overheating

While heating honey makes it easier to work with, excessive heat can ruin the product. Overheating destroys beneficial enzymes, darkens the honey's color, and can alter its delicate flavor profile, ultimately degrading its quality and value.

The Challenge of Inconsistency

The most common mistake is assuming that the machine settings that worked yesterday will work today. Changes in ambient temperature or variations between different honey batches will alter viscosity, requiring recalibration.

Ignoring Objective Measurement

Relying on "feel" instead of data is unreliable. Professionals use a viscometer to get a precise measurement of viscosity, often in units called centipoise (cP). This data allows for precise, repeatable adjustments to machinery.

How to Apply This to Your Process

Your approach to managing viscosity should align directly with your primary business goal. Use these principles to guide your operational decisions.

- If your primary focus is consistency and accuracy: Maintain a stable and consistent temperature in your holding tanks and throughout the filling lines to ensure viscosity does not fluctuate.

- If your primary focus is speed and efficiency: Gently heat the honey to an optimal, safe temperature (e.g., 95-105°F or 35-40°C) to lower its viscosity, but monitor it closely to prevent product damage.

- If your primary focus is preserving raw honey quality: Minimize heating and instead invest in machinery designed for high-viscosity products, such as positive displacement pumps and larger nozzles, accepting a slower filling speed as the trade-off.

By treating viscosity as a key variable to be controlled, you gain mastery over the efficiency, accuracy, and quality of your entire honey filling operation.

Summary Table:

| Factor | Effect on Viscosity | Impact on Filling Process |

|---|---|---|

| Temperature | Higher temp = Lower viscosity | Faster flow, but risk of overheating and quality loss |

| Moisture Content | Lower moisture = Higher viscosity | Requires more pressure, slower speeds |

| Floral Source | Varies by type (e.g., Buckwheat is thick) | Requires equipment calibration for each honey type |

| Filling Speed/Pressure | N/A | Must be adjusted to match current viscosity for accuracy |

Struggling with inconsistent fills or slow production speeds?

At HONESTBEE, we understand that viscosity management is the key to a profitable honey filling operation. We supply commercial apiaries and beekeeping equipment distributors with the robust, high-performance filling equipment needed to master this critical variable.

Our experts can help you select the right pumps, nozzles, and temperature control systems to achieve the perfect balance between speed, accuracy, and product quality. Let's optimize your process together.

Contact our wholesale team today for a consultation to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How do automated honey packaging and filling machines increase commercial value? Scale Your Honey Business Profitably

- What is the distinction between intermittent-motion and continuous-motion honey stick machines? Compare Speed & Efficiency

- How does automatic honey filling and processing equipment contribute to the integrity of organic honey production?

- What is the technical value of an automatic honey filling machine? Precision Bottling for Diverse Floral Sources

- What features make jar or bottle packing machines suitable for honey packaging? Optimize for Viscosity and Purity

- How do industrial-grade honey filling machines ensure product quality? Precision & Hygiene for Large-Scale Output

- How do industrial-grade honey filling machines contribute to the processing of honeybee products? Maximize Safety & Scale

- Why exclude container weight in honey filling? Master Net Mass Accuracy with Industrial Machinery