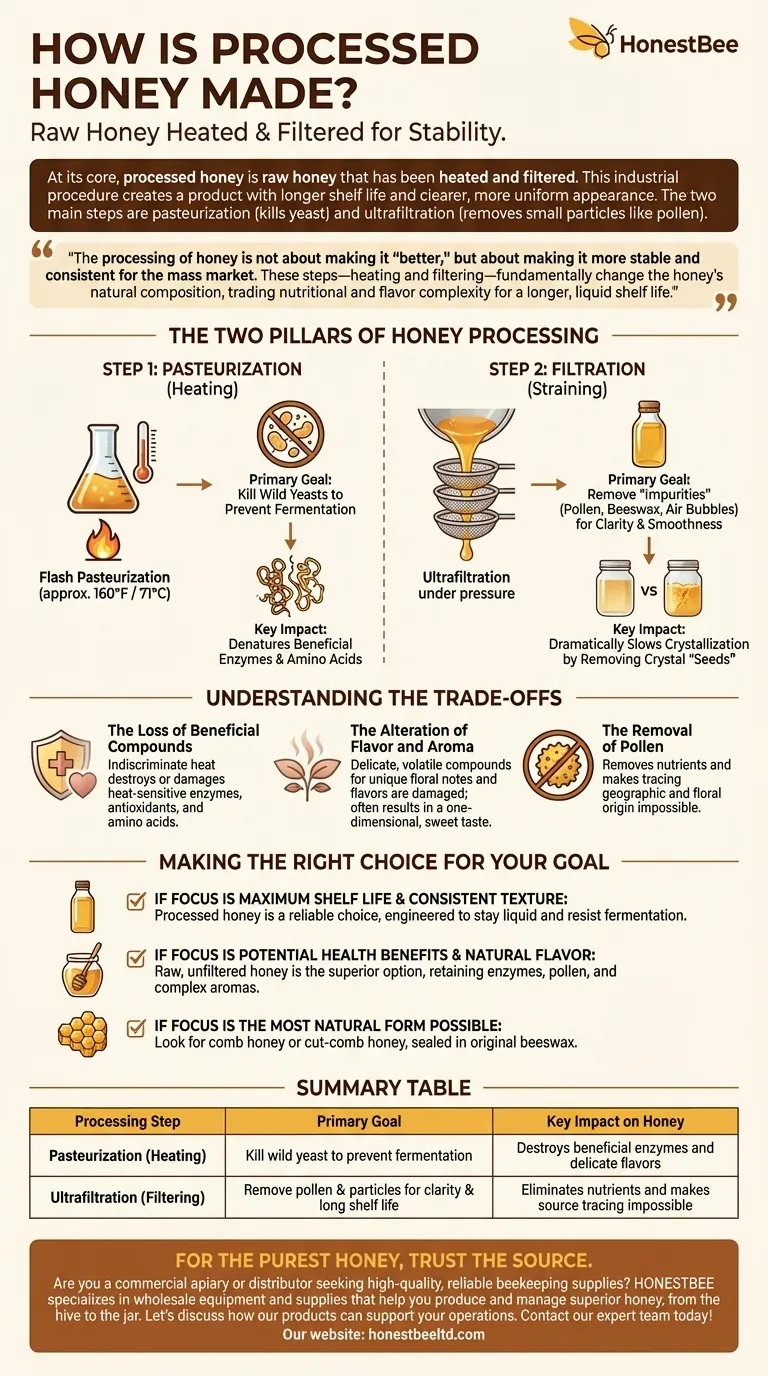

At its core, processed honey is raw honey that has been heated and filtered. This industrial procedure is designed to create a product with a longer shelf life and a clearer, more uniform appearance. The two main steps are pasteurization, which kills yeast, and ultrafiltration, which removes small particles like pollen.

The processing of honey is not about making it "better," but about making it more stable and consistent for the mass market. These steps—heating and filtering—fundamentally change the honey's natural composition, trading nutritional and flavor complexity for a longer, liquid shelf life.

The Two Pillars of Honey Processing

The transformation from raw to processed honey hinges on two key industrial actions. Each step serves a specific commercial purpose, but also has a significant impact on the final product.

Step 1: Pasteurization (Heating)

The first step is typically flash pasteurization. The honey is rapidly heated to a high temperature, often around 160°F (71°C), and then quickly cooled.

The primary goal of this heating is to kill naturally occurring wild yeasts. If left unchecked, these yeasts can cause the honey to ferment over time, especially if its water content is on the higher side.

However, this intense heat also denatures beneficial enzymes and amino acids that are naturally present in raw honey. These compounds are often the reason many people seek out honey for its health properties.

Step 2: Filtration (Straining)

After heating, the honey is often filtered under pressure. This process forces the honey through extremely fine filters to remove microscopic particles.

This filtration is done to remove all "impurities," including tiny flecks of beeswax, air bubbles, and, most importantly, pollen grains. The result is a perfectly clear and smooth liquid.

Removing these particles, particularly pollen, also removes the "seeds" around which honey crystals form. This dramatically slows down the natural process of crystallization, keeping the honey liquid on the shelf for much longer.

Understanding the Trade-offs

The decision to process honey is driven by commercial needs, but it comes with significant compromises to the honey's natural character.

The Loss of Beneficial Compounds

Pasteurization is effective at preventing fermentation, but the heat is indiscriminate. It destroys or damages the heat-sensitive enzymes, antioxidants, and amino acids that make raw honey a unique natural food.

The Alteration of Flavor and Aroma

The delicate, volatile compounds that give different types of honey their unique floral notes, aromas, and distinct flavors are damaged by high heat. Processed honey often has a more one-dimensional, simply sweet taste compared to the complexity of its raw counterpart.

The Removal of Pollen

Filtering out pollen creates a visually clear product, but it also removes a key part of the honey. Pollen is a source of nutrients and is the only definitive way to trace honey back to its specific geographic and floral origin. Without pollen, verifying the source of the honey becomes nearly impossible.

Making the Right Choice for Your Goal

Understanding the "how" and "why" behind processed honey empowers you to select the right product based on your specific needs.

- If your primary focus is maximum shelf life and consistent texture: Processed honey is a reliable choice, as it is engineered to stay liquid and resist fermentation for a very long time.

- If your primary focus is potential health benefits and natural flavor: Raw, unfiltered honey is the superior option, as it retains the enzymes, pollen, and complex aromas from its source.

- If your primary focus is the most natural form possible: Look for comb honey or cut-comb honey, where the honey is still sealed in the original beeswax comb it was made in.

Ultimately, knowing how honey is treated allows you to choose the product that best aligns with your priorities for flavor, nutrition, and use.

Summary Table:

| Processing Step | Primary Goal | Key Impact on Honey |

|---|---|---|

| Pasteurization (Heating) | Kill wild yeast to prevent fermentation | Destroys beneficial enzymes and delicate flavors |

| Ultrafiltration (Filtering) | Remove pollen & particles for clarity & long shelf life | Eliminates nutrients and makes source tracing impossible |

For the purest honey, trust the source. Are you a commercial apiary or distributor seeking high-quality, reliable beekeeping supplies? HONESTBEE specializes in wholesale equipment and supplies that help you produce and manage superior honey, from the hive to the jar. Let's discuss how our products can support your operations. Contact our expert team today!

Visual Guide

Related Products

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Professional Stainless Steel Honey Filtering Machine with Water Bath Heating for Beekeeping

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What is the purpose of the settling and filtration process after honey extraction? Master Honey Purity and Market Grade

- How does the decanting process in settling tanks contribute to honey purification? Achieve High Clarity Naturally

- What are the technical advantages of using professional filtration for honey? Optimize Clarity and Quality

- What is the primary purpose of multi-stage honey filtration? Achieve Visual Clarity and Purity Without Compromise

- What functions do high-precision filtering and moisture control equipment serve in honey refining? Ensure Pure Quality