The short answer is this: The plywood floor is not glued or nailed flat against the bottom of the frame, but is instead fitted into a special groove, called a dado slot, cut into the interior walls of the feeder. This method intentionally leaves room for the plywood to expand and contract with moisture, which is the most critical design feature for a long-lasting feeder.

The central principle of hive-top feeder construction is not achieving a tight, perfect fit. Instead, success hinges on creating a deliberate expansion gap by cutting the plywood floor slightly smaller than its housing, allowing it to swell with moisture without breaking the feeder's frame apart.

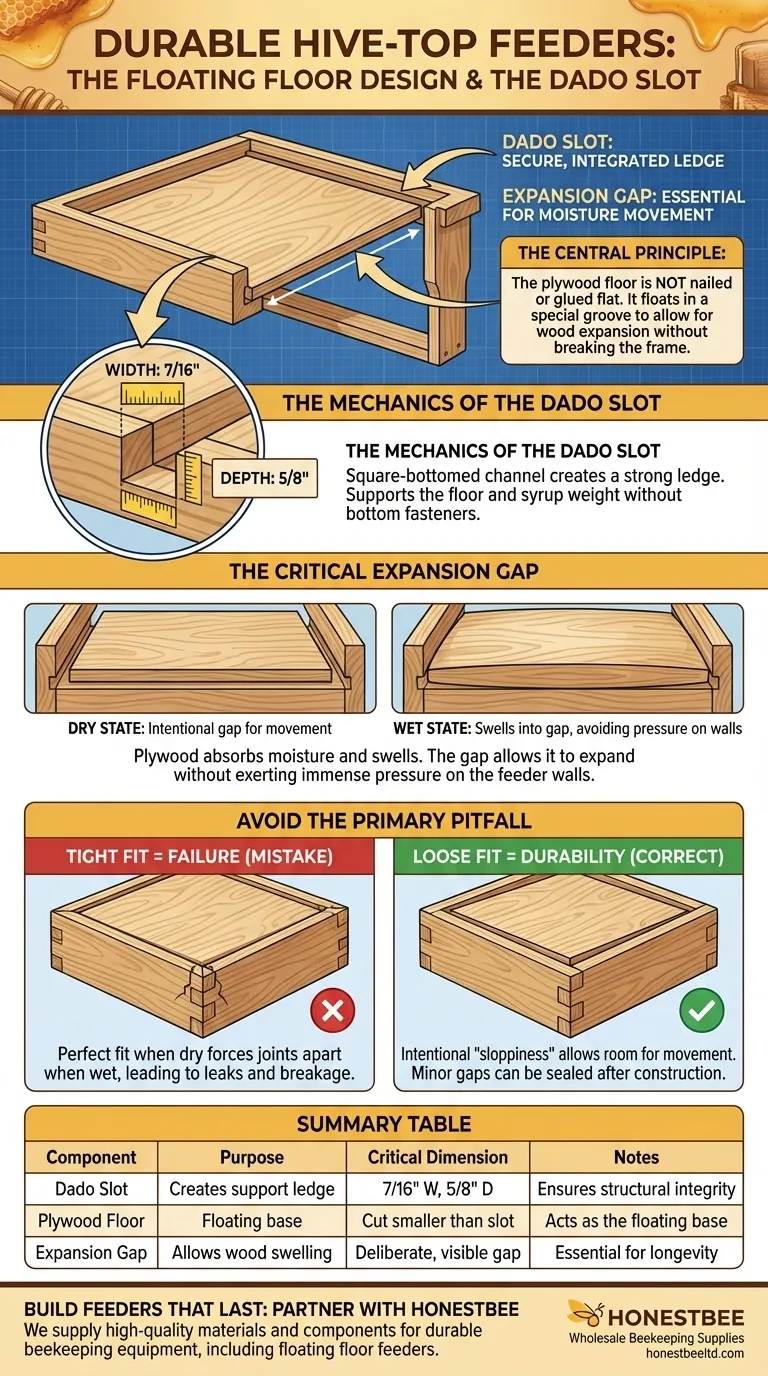

The Mechanics of the Dado Slot

A dado is simply a square-bottomed channel cut into a piece of wood. In this application, it creates a strong, integrated ledge that supports the plywood floor within the feeder's frame.

Why a Dado Slot is Used

This method provides structural integrity without relying on fasteners at the feeder's bottom joints. The slot ensures the floor is held securely in place while allowing it to "float" within the frame.

Setting the Correct Dimensions

For a robust and reliable fit, the dado slot is typically cut to a width of 7/16 inches and a depth of 5/8 inches. These dimensions provide ample surface area to support the floor and the weight of sugar syrup.

The Critical Role of the Expansion Gap

Wood, especially plywood, absorbs moisture and swells. A hive-top feeder is constantly exposed to humidity and liquid, making this expansion an absolute certainty. The design must accommodate this natural movement.

Sizing the Plywood Floor

The plywood floor must be cut so there is a small gap between its edges and the bottom of the dado slot. It should not fit snugly.

This extra room is the single most important factor in preventing feeder failure.

The Physics of Wood Expansion

When the plywood floor absorbs syrup or atmospheric moisture, it will expand in all directions. Without a gap to expand into, it will exert immense pressure outwards on the feeder's frame walls.

The Primary Pitfall to Avoid

The most common mistake in building a hive-top feeder is striving for a perfect, cabinet-grade fit. This instinct is counterproductive and leads to rapid failure.

The Consequence of a Tight Fit

A floor that fits perfectly when the wood is dry will inevitably swell when wet. This expansion will force the feeder's corner joints apart, breaking the box and causing it to leak.

A Loose Fit is the Correct Fit

The goal is a floor that sits securely in the slot but has noticeable room to move. This intentional "sloppiness" is the key to its durability. Any minor gaps can be sealed with beeswax or a food-safe sealant after construction.

Making the Right Choice for Your Goal

Building equipment that withstands the harsh conditions of an apiary requires designing for the reality of wood movement.

- If your primary focus is longevity: Ensure you cut the plywood floor with an obvious expansion gap and liberally seal the interior of the feeder with beeswax or a non-toxic sealant.

- If your primary focus is avoiding leaks: Do not rely on a tight wood-to-wood fit. Rely on a proper seal applied after construction, allowing the wood itself room to move freely.

Ultimately, accepting that wood moves and planning for that movement is the key to building equipment that will last for years.

Summary Table:

| Component | Purpose | Critical Dimension |

|---|---|---|

| Dado Slot | Creates a ledge to support the plywood floor | 7/16" width, 5/8" depth |

| Plywood Floor | Acts as the floating base of the feeder | Cut smaller than the slot to create an expansion gap |

| Expansion Gap | Allows wood to swell with moisture without breaking the frame | A deliberate, visible gap is essential |

Build Feeders That Last: Partner with HONESTBEE for Your Beekeeping Supplies

Constructing durable, reliable equipment is fundamental to successful beekeeping. The principles of a floating floor—using precise dado slots and expansion gaps—apply to all quality woodenware.

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with wholesale-focused operations, providing the high-quality materials and components needed to build equipment that withstands the test of time and the elements.

Let us be your partner in building a stronger operation.

Contact HONESTBEE today to discuss your wholesale supply needs for feeders, hive bodies, and other essential equipment.

Visual Guide

Related Products

- Professional Hive Top Bee Feeder for Beekeeping

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- HONESTBEE Round Hive Top Bee Feeder for Syrup

- Boardman Entrance Bee Feeder Durable Galvanized Steel and Wood Construction for Beekeeping

- Professional Hive Front Entrance Bee Feeder

People Also Ask

- What types of hive boxes is the round hive top feeder compatible with? Universal Fit for 8 & 10-Frame Langstroth Hives

- What is a top feeder for bees? Maximize Colony Health with Efficient Feeding

- Why is a top feeder essential for bees? Ensure Colony Health and Efficiency

- How to use a top feeder in a beehive? A Guide to Effective Beehive Feeding

- Do I need an inner cover with a hive top feeder? Optimize Your Hive Setup for Healthy Bees