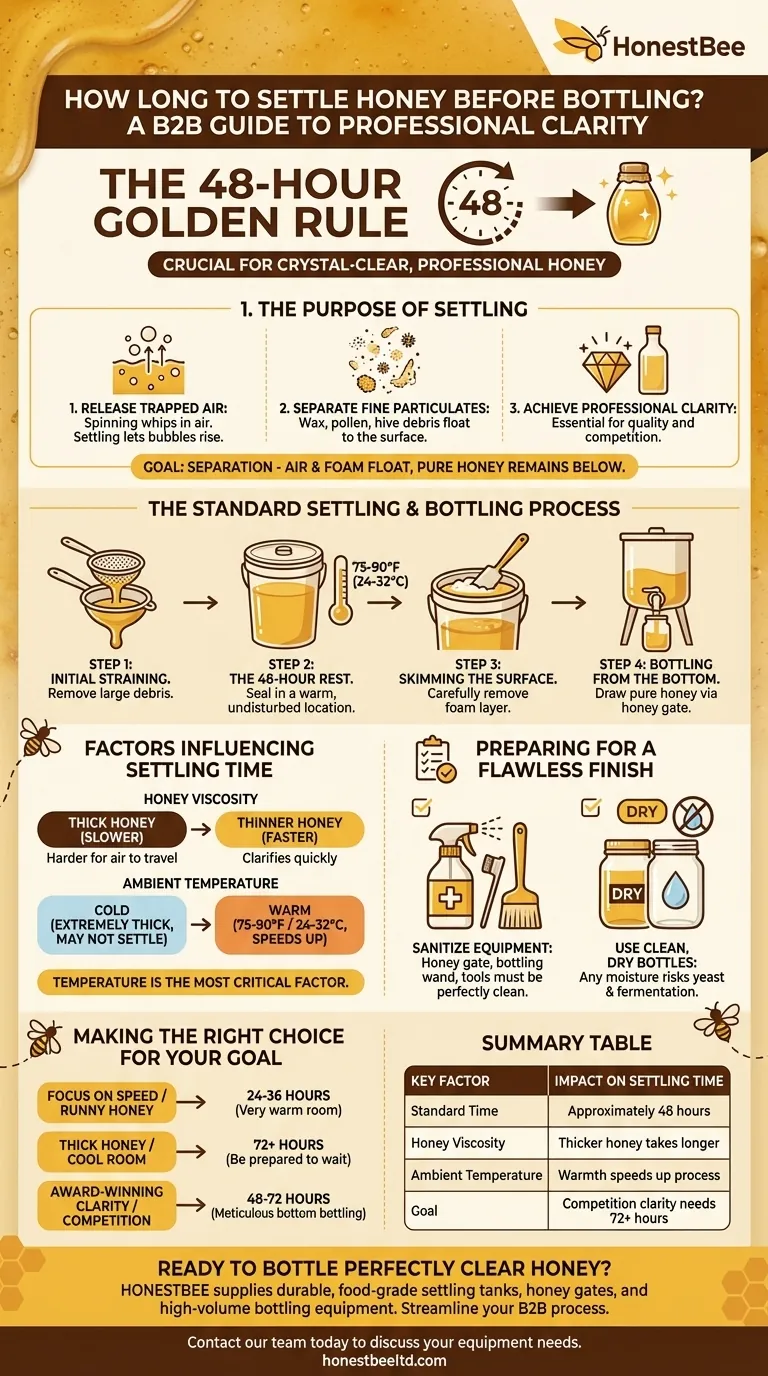

As a general rule, honey should be left in a settling tank for approximately 48 hours before you begin bottling. This crucial waiting period allows the tiny air bubbles introduced during extraction to rise to the surface, along with any fine wax particles, resulting in a crystal-clear and professional final product.

The primary goal of settling is not just to pass time, but to achieve separation. This process ensures the air, foam, and fine debris float to the top, allowing you to bottle pure, clear honey from the bottom.

The Purpose of Settling Honey

After extraction, honey is often cloudy and filled with air. The settling process is designed to naturally purify and clarify the honey without excessive filtering, which can remove beneficial pollen.

Releasing Trapped Air

The process of spinning honey out of the comb whips a significant amount of air into it. These tiny bubbles create a foamy or cloudy appearance that is undesirable in the final bottle.

Letting the honey rest undisturbed allows this trapped air to slowly rise to the top, forming a foamy layer.

Separating Fine Particulates

Even after coarse straining, microscopic particles of wax, pollen, and other hive debris can remain suspended in the honey.

Because these particles are less dense than honey, they will gradually float to the surface during the settling period, joining the layer of foam.

Achieving Professional Clarity

The combined removal of air bubbles and fine particulates is what gives bottled honey its beautiful, jewel-like clarity. This visual appeal is a key indicator of quality for customers and is essential for competition-grade honey.

The Standard Settling and Bottling Process

Following a systematic approach ensures you don't waste your hard work from the harvest. The process is straightforward and requires little more than patience.

Step 1: Initial Straining

Immediately after extraction, your honey should be run through a strainer to remove large debris like wax cappings and bee parts. Many beekeepers use a double sieve, with a coarse filter on top and a finer one below.

Step 2: The 48-Hour Rest Period

Pour the strained honey into a food-grade settling tank. These tanks are typically buckets equipped with a honey gate (a type of valve) near the bottom.

Seal the tank and leave it in a warm, undisturbed location for about 48 hours.

Step 3: Skimming the Surface

After two days, you will see a distinct layer of white foam and wax particles on the surface. You can carefully skim this layer off the top with a spatula before you begin bottling.

Step 4: Bottling from the Bottom

The honey gate is positioned low on the tank for a reason. By bottling from the bottom, you draw off the pure, clear honey first, leaving the entire top layer of foam undisturbed. This is the most effective way to ensure no air gets into your jars.

Factors That Influence Settling Time

While 48 hours is a reliable benchmark, certain conditions can change how long you need to wait.

Honey Viscosity

Thicker honey with lower moisture content will settle more slowly, as it is harder for air bubbles to travel through it. Thinner, runnier honey may clarify faster.

Ambient Temperature

Temperature is the most critical factor. Warm honey is significantly less viscous and flows more easily.

Storing your settling tank in a warm room (ideally 75-90°F or 24-32°C) will dramatically speed up the process. Cold honey is extremely thick and may not settle properly at all.

Preparing for a Flawless Finish

A couple of final checks ensure the honey you bottle remains perfect.

Sanitize Your Equipment

Ensure your honey gate, bottling wand, and any other tools are perfectly clean before they touch the honey.

Use Clean, Dry Bottles

As the references note, bottling honey in clean and completely dry jars is non-negotiable. Any moisture, even a single drop of water, can introduce yeast and increase the risk of fermentation over time.

Making the Right Choice for Your Goal

Use the 48-hour rule as your guide, but adapt based on your specific conditions and desired outcome.

- If your primary focus is speed and the honey is runny: You might achieve good clarity in 24-36 hours, especially in a very warm room.

- If your honey is thick or the room is cool: Be prepared to wait 72 hours or more to ensure all the bubbles have risen.

- If your primary focus is award-winning clarity for sale or competition: Always wait the full 48-72 hours and be meticulous about bottling from the bottom of the tank without disturbing the surface.

Patience during the settling phase is the final, critical step to showcasing the quality of your harvest in every bottle.

Summary Table:

| Key Factor | Impact on Settling Time |

|---|---|

| Standard Time | Approximately 48 hours |

| Honey Viscosity | Thicker honey takes longer |

| Ambient Temperature | Warmth (75-90°F / 24-32°C) speeds up the process |

| Goal | Competition-grade clarity may require 72+ hours |

Ready to Bottle Perfectly Clear Honey?

For commercial apiaries and distributors, achieving a flawless, professional finish on every batch is essential for customer satisfaction and brand reputation. HONESTBEE supplies the durable, food-grade settling tanks, honey gates, and bottling equipment designed for high-volume, efficient operations.

Let our wholesale-focused expertise help you streamline your process. Contact our team today to discuss your equipment needs and ensure every jar of honey you sell showcases the quality of your harvest.

Visual Guide

Related Products

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Filter with Tripod Support Stand

- Stainless Steel Honey Storage Tank with Lid for Honey

People Also Ask

- What is the purpose of a settling tank or de-aerator in honey clarification? Achieve Professional Liquid Clarity

- What role do high-specification food-grade honey storage tanks play in the maturation process? | Pure Honey Solutions

- Why is the use of temperature-controlled storage tanks essential for honey? Secure Quality and Prevent Fermentation

- How do food-grade honey storage tanks and filling equipment contribute to the commercialization of bee products?

- Can I store honey in stainless steel? A Guide to Safe, Long-Term Honey Storage