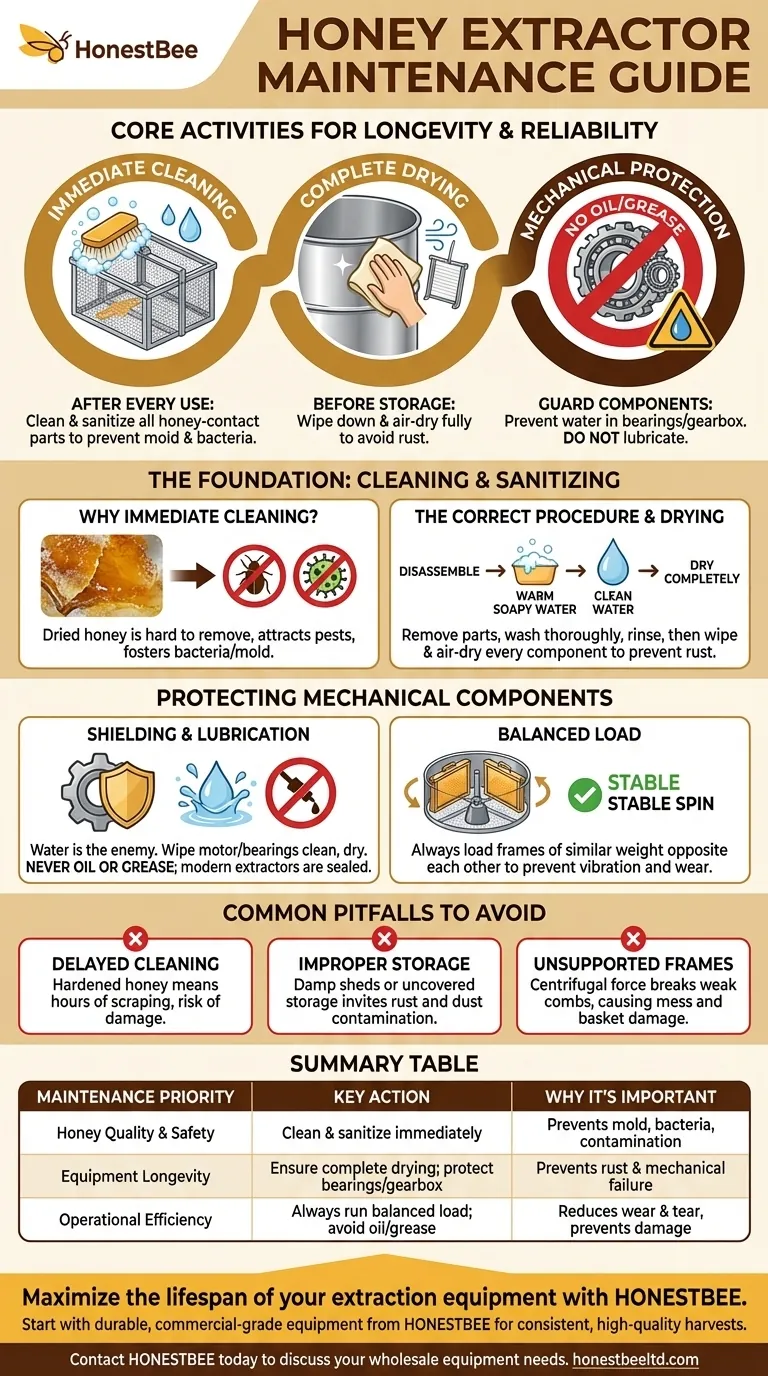

Proper maintenance of a centrifuge honey extractor hinges on three core activities: immediate cleaning after every use, complete drying before storage, and careful protection of its mechanical components. You must clean and sanitize all parts that contact honey to prevent mold and bacteria, then store the entire unit in a dry, protected area to avoid rust and damage. Critically, you should never oil or grease the extractor and must prevent water from reaching the bearings or gearbox.

The longevity and reliability of your honey extractor are determined not by complex mechanical repairs, but by consistent, disciplined cleaning and preventative care. Your goal is to protect both the quality of your honey and the integrity of the machine itself.

The Foundation: Cleaning and Sanitizing

Proper cleaning is the most critical maintenance task you will perform. It ensures food safety and makes every subsequent use easier.

Why Immediate Cleaning is Non-Negotiable

Honey that is allowed to dry and crystallize inside an extractor becomes extremely difficult to remove. This residue can also attract pests and foster the growth of bacteria and mold, which can contaminate future honey harvests.

The Correct Cleaning Procedure

Begin cleaning as soon as you have finished extracting. Disassemble any removable parts, such as the gate or baskets. Wash all surfaces that came into contact with honey thoroughly using warm, soapy water and a soft cloth or brush.

After washing, rinse all components completely with clean water to remove any soap residue.

The Importance of Thorough Drying

Once clean, every part of the extractor must be dried completely. Wipe it down with a dry cloth and allow it to air-dry fully before reassembly or storage. This step is essential for preventing rust, especially on stainless steel welds and non-stainless components.

Protecting the Mechanical Components

While the drum and baskets require cleaning, the motor, gearbox, and bearings require protection. These parts are the heart of your extractor and are susceptible to damage from improper care.

Shielding Bearings and the Gearbox

Water is the primary enemy of your extractor's mechanical systems. When cleaning, be extremely careful to prevent water from splashing or running into the motor housing, bearings, or gearbox. These areas should be wiped clean with a dry or slightly damp cloth only.

To Grease or Not to Grease?

Modern honey extractors, especially those with sealed bearings, are designed to be maintenance-free in this regard. Do not oil or grease the extractor. Adding lubricants can attract dust and honey particles, creating a sticky, damaging paste and potentially contaminating your honey. If you suspect a bearing issue, consult the manufacturer.

The Critical Role of a Balanced Load

A major cause of premature wear is running the extractor with an unbalanced load. Unevenly weighted frames cause severe vibration, putting immense stress on the bearings, motor, and the entire structure. Always load frames of similar weight directly opposite each other to ensure a smooth, stable spin.

Common Pitfalls to Avoid

Simple mistakes in operation or storage can significantly shorten the life of your extractor. Being aware of them is a key part of maintenance.

The Risk of Delayed Cleaning

Postponing cleaning is the most common mistake. What takes minutes with fresh, liquid honey can take hours of scraping and soaking once it has hardened, increasing the risk of scratching surfaces or damaging components.

The Danger of Improper Storage

Storing an extractor in a damp shed or barn invites rust and corrosion. Storing it uncovered can allow dust and debris to contaminate the mechanical parts. Always choose a clean, dry, and cool location for storage.

Using Unsupported Frames

Never use frames that lack proper wire or plastic foundation support. The centrifugal force is powerful enough to break these combs apart, creating a significant mess and potentially damaging the extractor's baskets.

Making the Right Choice for Your Process

Your maintenance routine should align with your primary goals as a beekeeper.

- If your primary focus is honey quality and food safety: Your top priority is immediate, thorough cleaning and sanitizing after every single use to prevent any contamination.

- If your primary focus is equipment longevity: You must protect the mechanicals by keeping them dry, avoiding unauthorized lubrication, and always running balanced loads to minimize wear.

- If your primary focus is efficiency: Clean the extractor while the honey residue is still warm and liquid to save significant time and effort later on.

By treating your extractor with consistent care, you ensure it remains a reliable tool for every future harvest.

Summary Table:

| Maintenance Priority | Key Action | Why It's Important |

|---|---|---|

| Honey Quality & Safety | Clean & sanitize immediately after use | Prevents mold, bacteria, and honey contamination |

| Equipment Longevity | Ensure complete drying; protect bearings/gearbox from water | Prevents rust and mechanical failure |

| Operational Efficiency | Always run a balanced load; avoid oil/grease | Reduces wear and tear, prevents damage |

Maximize the lifespan of your extraction equipment with HONESTBEE.

Proper maintenance is key, but starting with durable, commercial-grade equipment makes the process easier and more effective. HONESTBEE supplies robust honey extractors and beekeeping supplies designed for the demands of commercial apiaries and distributors.

We help you protect your investment and ensure consistent, high-quality honey harvests season after season.

Contact HONESTBEE today to discuss your wholesale equipment needs and build a more reliable, efficient operation.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- What are the differences between manual and electric honey extractors? A Beekeeper's Guide to Power, Speed & Cost

- What should be considered when using a honey extractor to avoid damage? Ensure a Smooth, Efficient Harvest

- What is the purpose of a honey extractor in beekeeping? Boost Hive Productivity & Honey Yields

- How do automated honey extractors reduce physical strain for beekeepers? Boost Efficiency & Prevent Burnout

- How long should you spin honey? Master the Art of Efficient, Damage-Free Extraction