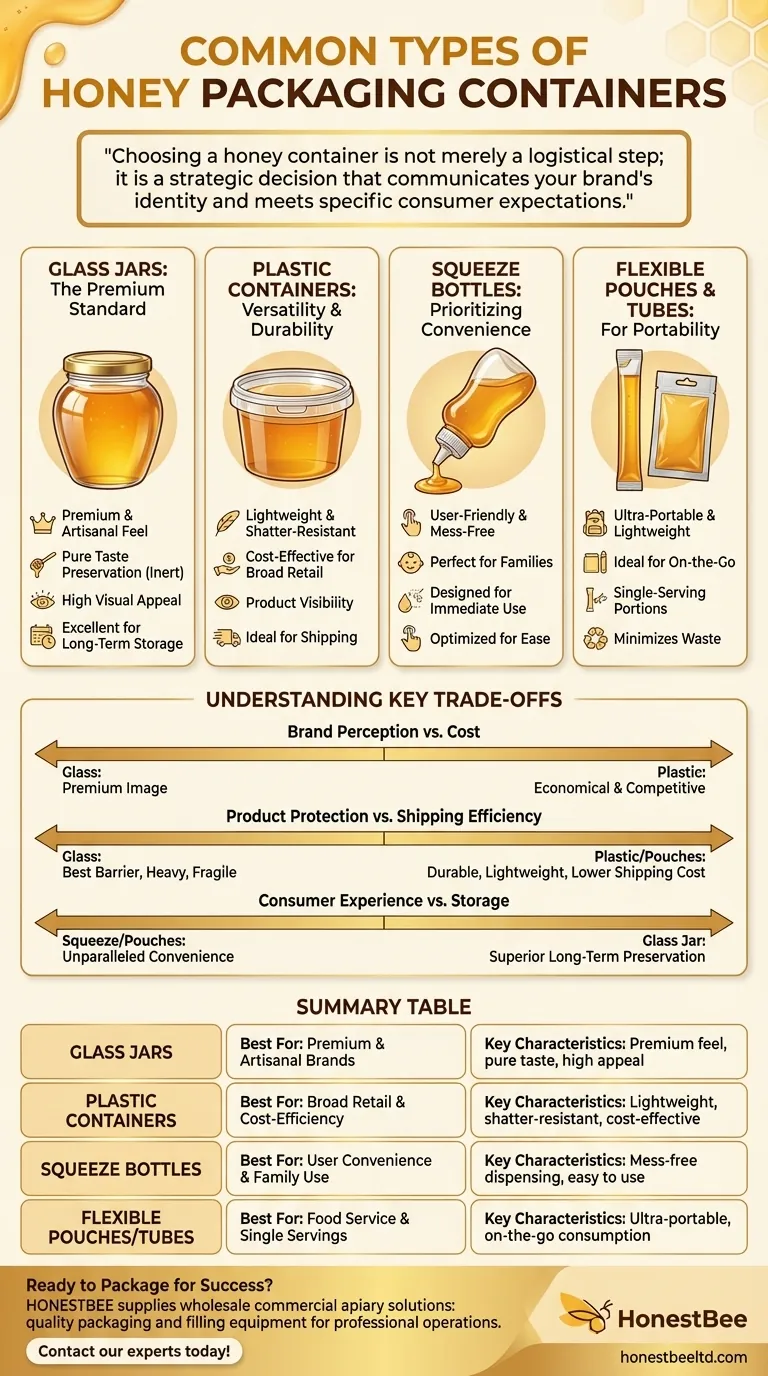

The most common types of honey packaging are glass jars, plastic containers (including squeeze bottles), and flexible pouches or tubes. Each material serves a distinct purpose, balancing factors like brand perception, consumer convenience, product protection, and cost.

Choosing a honey container is not merely a logistical step; it is a strategic decision that communicates your brand's identity and meets specific consumer expectations, from premium artisanal appeal to on-the-go convenience.

The Primary Packaging Options Explained

Understanding the inherent qualities of each packaging type is crucial for matching your product to its intended market and consumer.

Glass Jars: The Premium Standard

Glass is the traditional and most premium choice for honey. Its complete inertness ensures that it will not impart any flavor to the honey, preserving its pure taste.

The clarity and heft of glass signal a high-quality, artisanal product. Classic shapes like the queenline jar are instantly recognizable to consumers and offer excellent visual appeal on retail shelves.

Plastic Containers: Versatility and Durability

Plastic containers are a lightweight, low-cost, and shatter-resistant alternative to glass. This durability makes them ideal for shipping and reduces potential losses from breakage.

Being transparent, they still allow customers to see the product, a key purchasing factor for honey. Their versatility makes them suitable for a wide range of honey products aimed at a broad market.

Squeeze Bottles: Prioritizing Convenience

Squeeze bottles, typically made from PET or other plastics, are designed for user-friendly, mess-free dispensing. This feature is highly valued by families and frequent consumers.

While the product inside may be the same as in a jar, the packaging itself is optimized for ease of use rather than long-term, premium storage.

Flexible Pouches & Tubes: For Portability and Single Servings

Pouches, sachets, and tubes (like "honey sticks") are perfect for single-serving portions. They are extremely lightweight and ideal for on-the-go consumption or food service applications.

This format minimizes waste for small quantities but offers less protection for the product over the long term compared to rigid glass or plastic containers.

Understanding the Key Trade-offs

Selecting the right packaging requires a careful evaluation of competing priorities. No single option is perfect for every scenario.

Brand Perception vs. Cost

Glass jars project a premium, natural image but come with higher material and shipping costs. Plastic is more economical, making it a practical choice for producers focused on accessibility and competitive pricing.

Product Protection vs. Shipping Efficiency

Glass offers the best barrier against moisture and oxygen, preserving the honey perfectly. However, it is heavy and fragile.

Plastic and flexible pouches are significantly lighter and more durable, which lowers shipping costs and minimizes the risk of damage during transit.

Consumer Experience vs. Storage

Squeeze bottles and single-serving pouches offer unparalleled convenience for immediate use. Conversely, a sealed glass jar is superior for long-term pantry storage and preservation, which is often expected for high-end, raw honey.

A Note on Production and Machinery

The packaging you choose directly impacts the equipment needed for production. The process typically involves filling, capping, and labeling machines.

Different container types may require specific machinery. For instance, piston filling machines are often used to dispense precise, thick amounts of honey into jars, while other systems are better suited for lightweight pouches.

Making the Right Choice for Your Goal

Your final decision should be guided by your brand strategy and target consumer.

- If your primary focus is a premium, artisanal brand: Glass jars are the definitive choice to convey purity, quality, and tradition.

- If your primary focus is broad retail and cost-efficiency: Plastic containers provide the best balance of low cost, durability, and visual appeal for a mass-market audience.

- If your primary focus is user convenience and family appeal: Plastic squeeze bottles offer the mess-free experience that modern consumers value for everyday use.

- If your primary focus is food service or single-use portions: Flexible pouches and sachets deliver unmatched portability and portion control for on-the-go products.

Ultimately, your packaging is the first interaction a customer has with your product; ensure it tells the right story.

Summary Table:

| Packaging Type | Best For | Key Characteristics |

|---|---|---|

| Glass Jars | Premium & Artisanal Brands | Premium feel, pure taste preservation, high visual appeal |

| Plastic Containers | Broad Retail & Cost-Efficiency | Lightweight, shatter-resistant, cost-effective |

| Squeeze Bottles | User Convenience & Family Use | Mess-free dispensing, easy to use |

| Flexible Pouches/Tubes | Food Service & Single Servings | Ultra-portable, ideal for on-the-go consumption |

Ready to package your honey for success? The right container is just the start. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality packaging and filling equipment needed for efficient, professional-scale operations. From durable jars to precise piston fillers, we provide the wholesale solutions to help your brand thrive. Contact our experts today to discuss your packaging needs!

Visual Guide

Related Products

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Plastic Honey Gate Spout with Wing Nut for Beekeeping Honey Bucket

- Premium Diamond-Faceted Glass Honey Dispenser

People Also Ask

- What role does specialized packaging play in marketing and preservation? Master Honey Branding & Quality

- What is done with the honey after extraction and filtering? From Purification to Perfect Packaging

- What key functions do high-quality packaging materials serve? Unlock the Commercial Potential of Your Honey

- Why are Glass Jars preferred as storage equipment for honey? The Ultimate Choice for Purity and Long-Term Quality

- How does the appearance of glass jar packaging affect the sales and perception of honey? Boost Your Premium Brand Value