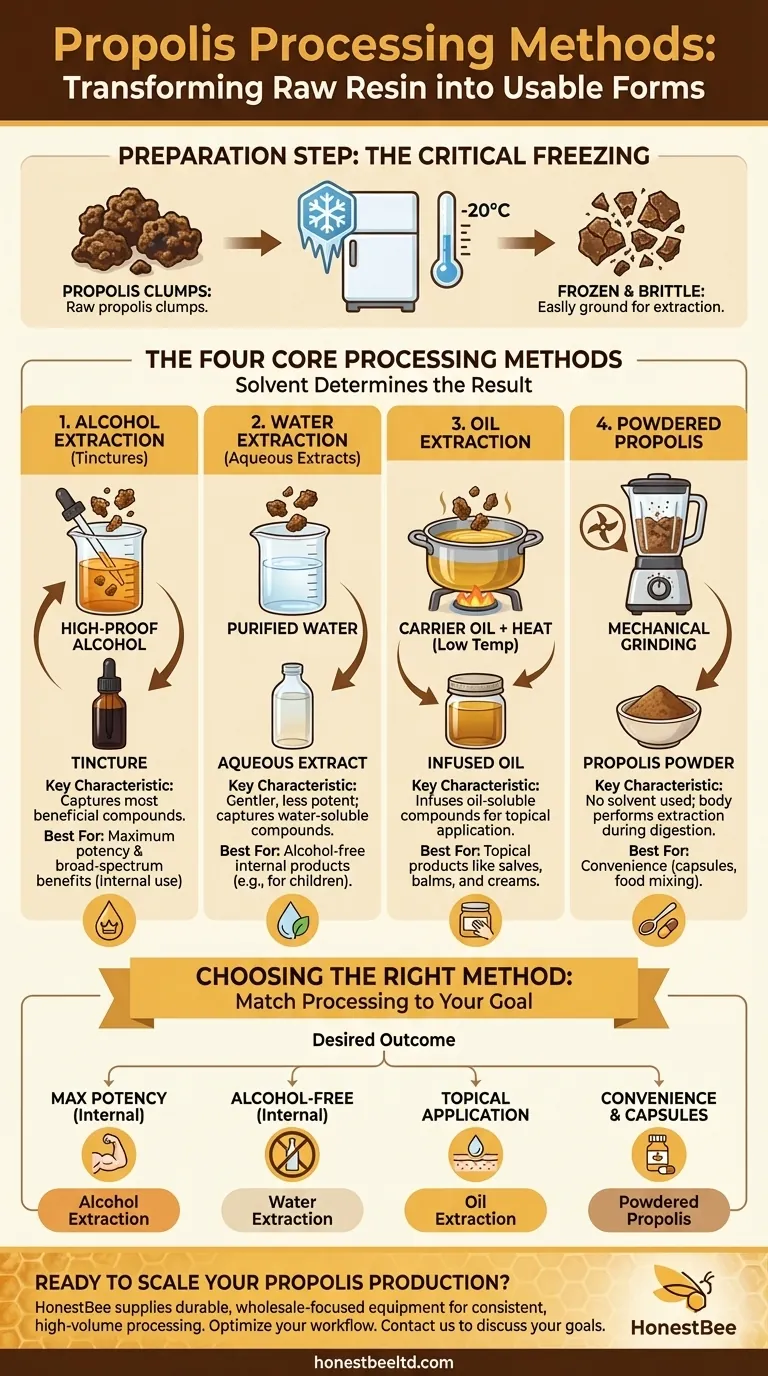

To transform raw propolis into a usable product, you must first extract its beneficial compounds from the raw resin. The four primary methods to accomplish this are alcohol extraction (tinctures), water extraction (aqueous solutions), oil extraction, and simple mechanical grinding to create a powder. Each technique is suited for different applications, as the solvent used determines which compounds are ultimately captured in the final product.

The processing method you choose is the most critical decision you will make. It directly dictates the potency, chemical profile, and potential use of your final propolis product, as different solvents like alcohol, water, and oil extract different beneficial compounds.

A Note on Preparation: The First Step

Before any extraction can begin, you must process the raw propolis collected from the hive. Raw propolis is a sticky, gummy resin at room temperature.

The Critical Freezing Step

To work with propolis, it must first be frozen for several hours. Freezing makes the resin extremely brittle, allowing it to be easily broken, shattered, or ground into smaller pieces. This dramatically increases the surface area, which is essential for an effective extraction.

The Four Core Processing Methods

Once your propolis is frozen and broken into small pieces, you can choose an extraction method based on your intended use.

Method 1: Alcohol Extraction (Tinctures)

This is the most common and scientifically studied method for creating a potent, broad-spectrum propolis extract. High-proof, food-grade alcohol is an excellent solvent for the vast majority of beneficial flavonoids and phenolic compounds in propolis.

The process involves soaking the crushed propolis in alcohol for several weeks, shaking it periodically. The resulting liquid, a tincture, is then strained and is ready for use.

Method 2: Water Extraction (Aqueous Extracts)

Water extraction is an alternative for those who must avoid alcohol. The process is similar to making a tincture, but uses purified water as the solvent.

This method is gentler but also less efficient. Water primarily extracts water-soluble compounds and will not capture the full range of resinous, alcohol-soluble components. The resulting product is less potent but suitable for certain applications.

Method 3: Oil Extraction

This technique is ideal for creating propolis-infused products for topical use, such as salves, balms, or creams. Crushed propolis is gently heated in a carrier oil (like olive, coconut, or jojoba oil) over a low, controlled temperature.

The gentle heat helps the oil-soluble compounds infuse into the carrier oil. The mixture is then strained to remove the solid propolis material, leaving a therapeutic, infused oil.

Method 4: Powdered Propolis

The simplest method is purely mechanical. After freezing, the brittle propolis is placed in a strong grinder or blender and pulverized into a fine powder.

This does not extract any compounds but instead creates a format that can be easily placed into capsules or mixed into foods like smoothies or yogurt. The body then performs the extraction during digestion.

Understanding the Trade-offs

Choosing a method requires weighing the desired potency against the final application. No single method is universally superior; each serves a different purpose.

Potency vs. Suitability

Alcohol extraction yields the most potent and comprehensive product, capturing the widest array of beneficial compounds. However, tinctures are not suitable for children, individuals with alcohol sensitivities, or for certain religious reasons. Aqueous extracts are far more suitable for these groups but offer lower potency.

Target Application Defines the Method

The end product dictates the process. If you intend to create a skin salve, oil extraction is the only logical choice. For a highly concentrated internal supplement, a tincture is the standard. For simple encapsulation, powdering is the most direct route.

The Solvent Is Everything

The core principle is simple: the solvent determines the result. Alcohol pulls out alcohol-soluble compounds. Water pulls out water-soluble compounds. Oil pulls out oil-soluble compounds. Understanding this allows you to tailor the product to your specific goal.

Making the Right Choice for Your Goal

Use your primary objective to guide your decision on which processing method to use.

- If your primary focus is maximum potency and broad-spectrum benefits: Choose alcohol extraction to create a powerful tincture for internal use.

- If your primary focus is an alcohol-free product for internal use: Use water extraction to create a gentler, but less potent, aqueous solution.

- If your primary focus is creating a topical product like a salve or cream: Use oil extraction to infuse the propolis directly into a carrier oil.

- If your primary focus is convenience and easy consumption in food or capsules: Freeze and grind the propolis into a fine powder.

By matching the processing method to your end goal, you unlock the specific benefits of propolis most relevant to your needs.

Summary Table:

| Processing Method | Best For | Key Characteristic |

|---|---|---|

| Alcohol Extraction | Maximum potency & broad-spectrum benefits | Captures most beneficial compounds; creates a tincture. |

| Water Extraction | Alcohol-free internal products | Gentler, less potent; uses water as the solvent. |

| Oil Extraction | Topical products (salves, balms) | Infuses oil-soluble compounds into a carrier oil. |

| Powdered Propolis | Convenience (capsules, food mixing) | Simple mechanical grinding; no solvent used. |

Ready to Scale Your Propolis Production?

Choosing the right processing method is just the first step. Efficiently scaling your operation requires reliable, high-quality equipment. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for consistent, high-volume propolis processing.

Let us help you optimize your workflow. Contact our experts today to discuss the best equipment solutions for your specific extraction goals.

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Commercial 48-Frame Stainless Steel Honey Extractor

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- What are some techniques for removing stubborn propolis from a trap? Master the Freezing Method

- What are the advantages of using a professional Propolis Trap? Optimize Purity and Efficiency in Your Apiary

- What is the oven-based method for cleaning propolis hive scrapings? Efficient Propolis Purification Explained

- What role does propolis play in the hive? The Dual-Purpose Secret to Beehive Health

- What are the technical advantages of using specialized Propolis Traps? Boost Purity and Efficiency in Your Apiary

- What is propolis and what are its properties? Unlock the Power of 'Bee Glue'

- Why is high-concentration alcohol required in the extraction process of active ingredients from propolis? Propolis Secrets

- Why is it necessary to place propolis extract in a low-temperature environment? Essential Dewaxing Guide