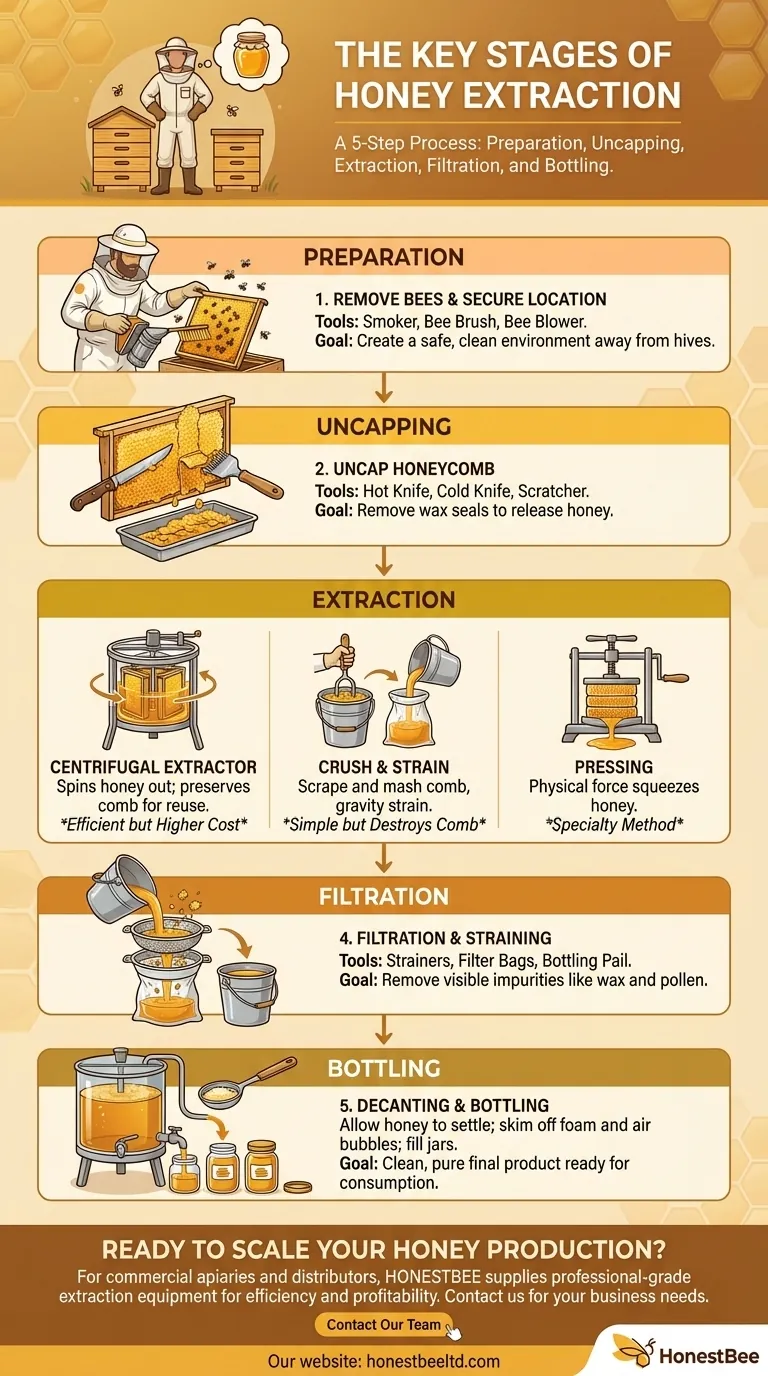

To extract honey, the process involves five key stages: removing the bees from the honeycomb frames, uncapping the wax-sealed cells, extracting the honey from the comb using force or gravity, filtering out impurities like wax and pollen, and finally, allowing the honey to settle before bottling.

The goal of any honey extraction method is to carefully separate pure honey from the beeswax comb and other hive debris. While modern centrifugal extractors are efficient and preserve the comb, simpler methods like crushing and straining offer a low-cost alternative, especially for new hobbyists.

Preparing for Extraction: The First Critical Steps

Before you can begin separating honey from the comb, you must create a safe and clean environment for the process. This initial preparation is crucial for both your safety and the quality of the final product.

Choosing the Right Location

Work at a distance from your hives. The potent smell of honey and exposed comb can agitate worker bees, creating a difficult and potentially dangerous working environment. An indoor, sealed space like a garage or kitchen is ideal.

Removing Bees from the Frames

Your first task is to gently clear the bees from the honey-filled frames you intend to harvest.

Several tools can accomplish this. A soft bee brush can be used to sweep bees off each frame, though this is slow. A bee blower is a faster but more disruptive method. Most commonly, a smoker is used to calm the bees and encourage them to move away from the frames you are taking.

The Core Extraction Process: From Comb to Liquid

Once the bees are cleared and you are in a secure location, the physical extraction begins. This involves opening the sealed honey cells and then getting the honey out.

Step 1: Uncapping the Honeycomb

Bees seal each cell of finished honey with a fresh layer of beeswax, called a capping. You must remove this layer to release the honey.

Common uncapping tools include a hot knife, which melts through the wax caps, or a cold knife or uncapping scratcher, which manually cuts or scrapes the caps away. The removed cappings, which are rich with honey, should be saved for later processing.

Step 2: Separating Honey from the Comb

This is the central stage where the honey is removed from the uncapped frames. There are three primary methods to achieve this.

The most common method is using a centrifugal honey extractor. Frames are placed inside this device, which spins them rapidly. The centrifugal force pulls the honey out of the cells and onto the walls of the extractor, where it drips down to be collected.

A simpler, lower-cost method is crush and strain. Here, the entire honeycomb is scraped off the frame and mashed up. This mixture is then placed in a filter or strainer bag, and gravity slowly pulls the honey out, leaving the wax behind.

A less common but effective method for certain setups is pressing. This involves using a honey press to physically squeeze the honey out of the comb, similar to pressing grapes for wine.

Refining and Purifying the Harvest

Raw honey straight from the comb contains particles of beeswax, pollen, and other hive debris. The final stages are focused on creating a clean, pure final product.

Filtration and Straining

After extraction, the honey is poured through a series of filters or strainers. This process removes the larger pieces of wax cappings and other visible impurities. This is often done using a bottling pail with filters.

Decanting and Clarifying

Even after straining, tiny air bubbles and micro-particles can remain suspended in the honey. The honey is left to sit in a sealed container for several days in a process called decanting or clarifying.

During this time, the lighter impurities and air bubbles rise to the surface, forming a foam that can be skimmed off before the honey is finally bottled.

Understanding the Trade-offs

Each extraction method has distinct advantages and disadvantages. The right choice depends on your budget, scale, and long-term goals as a beekeeper.

Centrifugal Extractors: Efficiency vs. Cost

Using an extractor is the fastest and most efficient method, especially for multiple hives. Its greatest benefit is that it preserves the empty honeycomb, which can be returned to the hive. The bees can immediately start refilling it, saving them the immense energy required to build new wax comb from scratch. The primary drawback is the significant upfront cost of the equipment.

Crush and Strain: Simplicity vs. Comb Loss

This method is extremely low-cost, requiring little more than a bucket and a strainer. It is an excellent starting point for new beekeepers with only one or two hives. The major trade-off is that it destroys the honeycomb, meaning the bees must expend significant resources to rebuild it before they can store more honey.

Cut Comb: The Purest Form

This isn't an extraction method in the traditional sense. Instead of separating the honey, you simply cut a piece of the sealed honeycomb out of the frame to be eaten as-is. This provides the most natural product but yields less liquid honey.

Making the Right Choice for Your Goal

Your goals as a beekeeper will determine the best extraction process for your needs.

- If your primary focus is a small-scale hobby: The crush and strain method offers a simple and affordable way to get started without a large investment.

- If your primary focus is maximizing honey production and bee efficiency: Investing in a centrifugal extractor is essential to preserve your drawn-out comb.

- If your primary focus is providing a natural, unprocessed product: Offering cut comb is a unique option that requires minimal equipment.

Ultimately, successfully extracting honey is a rewarding final step that honors the incredible work of your bees.

Summary Table:

| Stage | Key Action | Common Tools |

|---|---|---|

| 1. Preparation | Remove bees from frames; choose a clean location. | Bee brush, smoker, bee blower. |

| 2. Uncapping | Remove wax seals from honeycomb cells. | Hot knife, cold knife, uncapping scratcher. |

| 3. Extraction | Separate honey from the comb. | Centrifugal extractor (spinning), crush and strain, press. |

| 4. Filtration | Remove wax and debris from the raw honey. | Strainers, filter bags, bottling pail. |

| 5. Bottling | Allow honey to settle; skim foam; bottle the final product. | Settling tanks, storage buckets, bottles. |

Ready to scale your honey production?

For commercial apiaries and beekeeping equipment distributors, having reliable, high-quality extraction equipment is key to efficiency and profitability. HONESTBEE supplies the professional-grade tools you need—from centrifugal extractors to uncapping tanks and bottling systems—through our wholesale-focused operations.

Contact our team today to discuss your equipment needs and discover how we can support your business growth.

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What is the basic principle of the honey extractor? Harness Centrifugal Force for Efficient Harvesting

- What is the necessity of 1:2 ratio bevel gears in manual honey extractors? Optimize Extraction Speed and Efficiency

- Which type of extractor is more suitable for hobbyists or small-scale beekeepers? Find the Perfect Fit for Your Apiary

- How many frames can different types of honey extractors hold? Maximize Your Harvest Efficiency

- What tips can maximize honey extraction efficiency? Unlock Higher Yields and Purer Honey