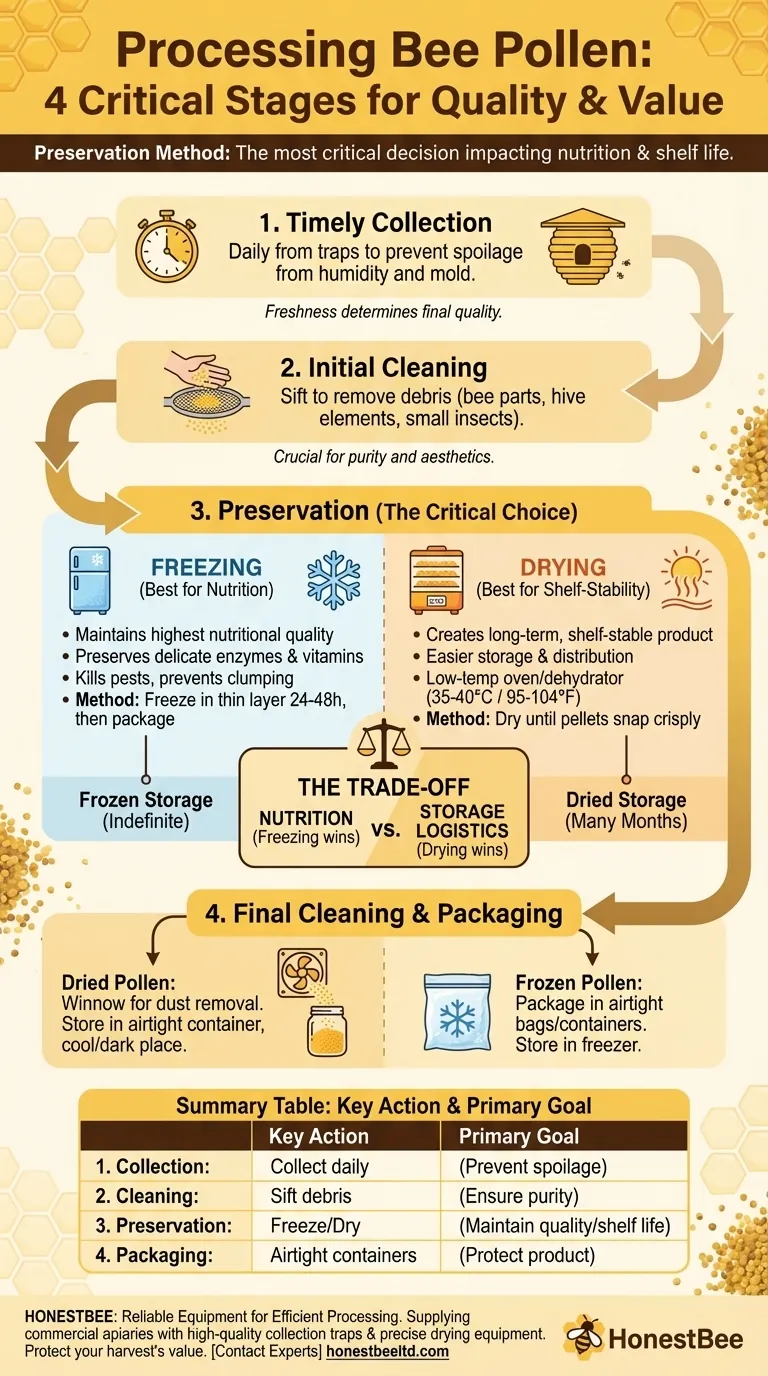

Properly processing bee pollen involves four critical stages: timely collection from traps, meticulous cleaning to remove impurities, preservation to maintain quality, and correct packaging for storage. The most important decision you will make is the preservation method, as this directly impacts the pollen's nutritional value and shelf life.

The method you choose for preservation—either freezing or drying—is the most critical decision in pollen processing. Freezing is the superior choice for preserving nutritional value and freshness, while drying offers long-term, shelf-stable storage at the cost of some nutrient degradation.

The Four Stages of Pollen Processing

To ensure a high-quality final product, whether for human consumption or for your bees, each stage of processing must be handled with care. The process begins the moment the pollen enters the collection trap.

Stage 1: Timely Collection

The quality of your finished pollen is determined by the freshness of the raw material. Pollen in a collection trap is exposed to humidity and can begin to mold or degrade quickly.

For this reason, pollen should be collected from traps daily, especially in humid climates. This regular collection is the first line of defense against spoilage and ensures you are starting with the best possible product.

Stage 2: Initial Cleaning

Once collected, the pollen must be cleaned to remove foreign debris. This often includes bee parts, hive debris, or small insects.

A preliminary cleaning can be done by sifting the pollen through a screen or by hand-picking larger contaminants. This step is crucial for both aesthetics and purity.

Stage 3: Preservation (The Critical Choice)

This is the most pivotal stage. Your choice of preservation will define the final product's characteristics. The two primary methods are freezing and drying.

Freezing is the preferred method for maintaining the highest nutritional quality. It preserves delicate enzymes, vitamins, and the fresh taste of the pollen. For best results, first freeze the fresh, cleaned pollen in a thin layer for 24-48 hours. This kills any potential pests and keeps the pellets from clumping together.

Drying creates a shelf-stable product. If you choose to dry, use a food dehydrator or a low-temperature oven set between 35-40°C (95-104°F). Exceeding this temperature will rapidly destroy nutrients. The pollen is fully dry when a pellet breaks with a crisp snap.

Stage 4: Final Cleaning and Packaging

After preservation, a final cleaning pass is often necessary, especially for dried pollen. Dried pellets are lighter and can be "winnowed" by pouring them in front of a low-speed fan to blow away any remaining dust or light debris.

For frozen pollen, package it in airtight freezer bags or containers. It can be stored in the freezer almost indefinitely without significant loss of quality.

For dried pollen, store it in airtight containers in a cool, dark, and dry place. Properly dried and stored pollen is shelf-stable for many months.

Understanding the Trade-offs: Freezing vs. Drying

Your decision to freeze or dry is not just about process; it's about balancing nutritional value against storage logistics.

Nutritional Integrity

Freezing is the clear winner for nutrition. It keeps the pollen in a state that is as close to its natural form as possible, preserving the full spectrum of beneficial compounds.

Drying, even at low temperatures, inevitably causes some degradation of heat-sensitive vitamins and enzymes.

Storage and Stability

Dried pollen is far easier to store and distribute. It does not require an unbroken cold chain, making it the standard for most commercial products sold on a shelf.

Frozen pollen requires significant freezer space and a consistent power source. Its distribution is limited to local customers or requires expensive cold-chain shipping.

Labor and Equipment

Drying requires a dehydrator and careful monitoring to avoid overheating. Freezing is simpler, requiring only freezer bags and available freezer space.

Alternative Processing Methods

While freezing and drying are the most common methods, two other techniques are used for specific purposes.

Creating "Bee Bread"

You can mix fresh pollen with honey to create a "pseudo bee bread." The mixture undergoes a natural lactic acid fermentation process, similar to what bees do in the hive. This can increase the bioavailability of nutrients and is an excellent way to prepare pollen for feeding back to your bees.

Making a Tincture

Pollen can also be preserved by creating an alcohol-based tincture. This extracts certain compounds into a liquid form, creating a concentrated supplement with a very long shelf life.

Making the Right Choice for Your Goal

Select your processing method based on your specific objective for the harvested pollen.

- If your primary focus is maximum nutritional value for personal use: Freezing is the unequivocal best method to preserve the pollen's full spectrum of benefits.

- If your primary focus is creating a shelf-stable product for commercial sale: Drying at a low, controlled temperature is the standard industry practice, despite some nutrient loss.

- If your primary focus is supplemental feeding for your own colonies: Freezing fresh pollen is ideal, but creating a fermented bee bread with honey can improve its digestibility for the bees.

By aligning your processing method with your end goal, you ensure the integrity and value of every pollen grain you harvest.

Summary Table:

| Stage | Key Action | Primary Goal |

|---|---|---|

| 1. Collection | Collect from traps daily | Prevent spoilage from humidity |

| 2. Cleaning | Sift to remove debris | Ensure purity and aesthetics |

| 3. Preservation | Freeze (best for nutrition) or Dry (best for shelf-stability) | Maintain quality and determine shelf life |

| 4. Packaging | Airtight containers (freezer or cool/dark place) | Protect the final product for storage |

Need reliable equipment to process your harvest efficiently?

As HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused supplies needed for every stage of pollen processing—from durable collection traps to precise drying equipment. Let us help you protect the value of your harvest.

Contact our experts today to discuss your specific needs and get a quote on professional-grade processing equipment.

Visual Guide

Related Products

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- 10L Stainless Steel Electric Honey Press Machine

- Professional Thermostatic Conical Honey Melter

- Plastic Chinese Queen Grafting Tool for Bee Queen Rearing

People Also Ask

- What is the specific function of mounted pollen traps in the non-destructive collection of pollen loads? | HONESTBEE

- What is the function of a modified pollen trap in SHB bioassays? Precision Dosing for Scientific Toxicity Research

- How do pollen traps and propolis collectors facilitate the diversification of bee products? Maximize Colony Revenue

- What is the function of a professional pollen trap in research? Maximize Data Accuracy & Foraging Insights

- What is the function of pollen traps in beehives? Boost Commercial Yield with Precision Harvesting Tools

- What are the key features of a well-designed pollen trap? Optimize Harvest & Hive Health

- What is the function of an automation control system in combined bee pollen drying equipment? Optimize Your Production

- What is the function of pollen traps? Boost Your Apiary Efficiency and Research Accuracy