At their core, honey filling machines operate on one of three main principles: piston, gravity, or pump-based systems. These mechanisms are designed to overcome honey's high viscosity, ensuring each container is filled with a precise and consistent volume. Many machines also incorporate heating elements to thin the honey for a smoother, more efficient flow.

The central challenge in filling honey is managing its thickness (viscosity). The choice of filling principle is therefore a strategic decision that balances the need for accuracy, production speed, and the specific consistency of your honey.

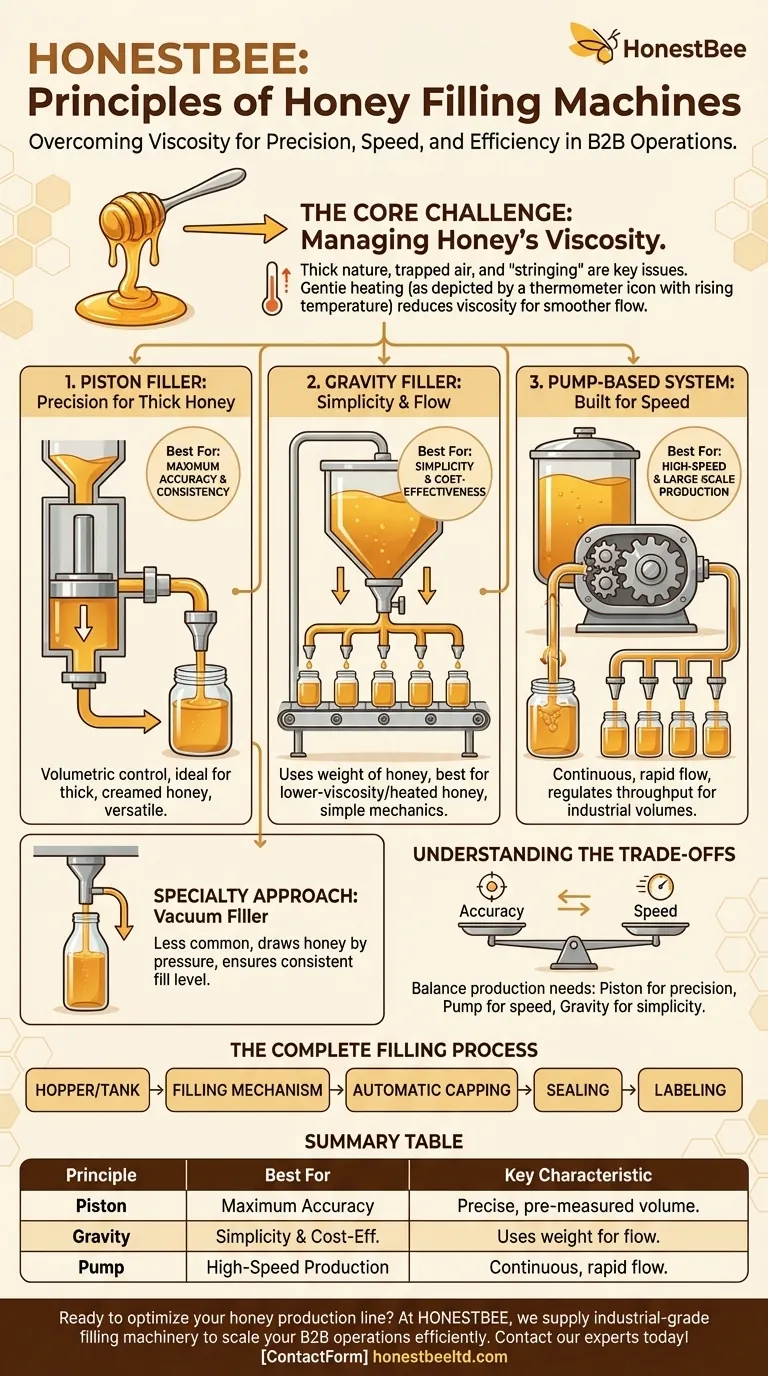

The Core Challenge: Managing Honey's Viscosity

Before examining the mechanics, it's essential to understand the unique problem honey presents. Its thick, viscous nature makes it difficult to handle compared to thinner liquids.

Why Viscosity Matters

Honey's thickness can trap air bubbles, lead to inconsistent fill levels, and cause "stringing" or dripping after a fill is complete. A machine's primary job is to control the honey's flow precisely to prevent these issues.

The Role of Temperature

Gently heating honey is a common practice to reduce its viscosity. By making the honey flow more easily, optional heating mechanisms in filling machines ensure a smoother, faster, and more accurate filling process, especially for thicker, raw honey.

Primary Filling Mechanisms Explained

Each filling technology offers a different solution to the viscosity challenge, tailored to specific production needs.

The Piston Filler: Precision for Thick Honey

This is the most common method for viscous products like honey. The machine uses a cylinder and a piston to draw in a precise volume of honey and then dispense it cleanly into the container. This volumetric approach offers extremely high accuracy.

The Gravity Filler: Simplicity and Flow

As the name suggests, this system relies on gravity. Honey is held in a hopper above the filling nozzles, and the weight of the honey itself forces it into the containers below. While simple and effective for lower-viscosity liquids, it can be adapted for thinner honey varieties.

The Pump-Based System: Built for Speed

For high-volume, industrial-scale operations, pump systems are the standard. These machines use various types of pumps (like gear or lobe pumps) to regulate a continuous and rapid flow of honey to the filling nozzles, prioritizing speed and throughput.

The Vacuum Filler: A Specialty Approach

Less common for honey but still a viable principle, a vacuum filler creates a vacuum inside the container. This pressure difference draws the honey from the hopper into the bottle, ensuring a consistent fill level relative to the container's volume.

Understanding the Trade-offs

No single principle is universally superior. The right choice depends on balancing competing operational priorities.

Accuracy vs. Speed

Piston fillers offer the highest level of accuracy because they dispense a pre-measured volume. Pump-based systems deliver the highest speed but may sacrifice a small degree of per-unit precision for overall throughput.

Product Versatility

Piston fillers are exceptionally versatile and can handle a wide range of viscosities, from thin honey to thick, creamed honey. Gravity fillers are more limited and work best with honey that has been warmed to a lower viscosity.

Mechanical Complexity

Gravity fillers are the simplest mechanically, often resulting in lower initial cost and easier maintenance. Piston and pump systems are more complex, requiring more precise engineering and calibration.

The Complete Filling Process

The filling mechanism is just one part of a larger automated workflow.

From Hopper to Container

In most systems, honey is first loaded into a large storage tank or hopper. From there, gravity or a feeding pump ensures a continuous supply is available to the primary filling system.

Ancillary Functions

A fully automated line integrates other critical steps. After the containers are positioned and filled, they move on to automatic capping or sealing machines. The final step is often labeling before the product is ready for packaging.

Making the Right Choice for Your Operation

Selecting the correct filling principle is fundamental to creating an efficient and reliable production line.

- If your primary focus is maximum accuracy with thick, unfiltered honey: A piston filler is the industry standard for its precise, volumetric control.

- If your primary focus is high-speed, large-scale production: A pump-based system is engineered to deliver the necessary volume and throughput.

- If your primary focus is a simple, cost-effective solution for lower-viscosity honey: A gravity filler provides a straightforward and reliable mechanism.

Ultimately, understanding these core principles empowers you to choose the technology that best preserves your product's quality while meeting your specific production goals.

Summary Table:

| Filling Principle | Best For | Key Characteristic |

|---|---|---|

| Piston Filler | Maximum Accuracy | Dispenses a precise, pre-measured volume. Ideal for thick honey. |

| Gravity Filler | Simplicity & Cost-Effectiveness | Uses the weight of honey for flow. Best for lower-viscosity honey. |

| Pump-Based System | High-Speed Production | Provides a continuous, rapid flow for large-scale operations. |

Ready to optimize your honey production line?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the precise, durable filling machinery they need to scale their operations efficiently. Our wholesale-focused operations mean you get industrial-grade equipment built to handle the unique challenges of honey.

Let us help you select the perfect piston, gravity, or pump-based system to ensure accuracy, increase throughput, and preserve your product's quality.

Contact our experts today for a personalized consultation and quote!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What role do automatic honey-filling machines play in honey processing? Enhance Your Production Standards

- What are equipment used for filling? Match Your Product to the Perfect Filling Machine

- What is a piston honey filling machine and how does it operate? Precision Bottling for High-Viscosity Honey

- How do precision pH meters and automatic titration systems ensure honey quality before automatic filling?

- How do industrial automatic honey-filling machines help mitigate the impact of Varroa destructor? Boost Apiary Profits

- What is the significance of integrating automatic honey filling machines into large-scale apiary operations?

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- What is the advantage of the compact size of the honey filling machine? Maximize Efficiency in Limited Spaces