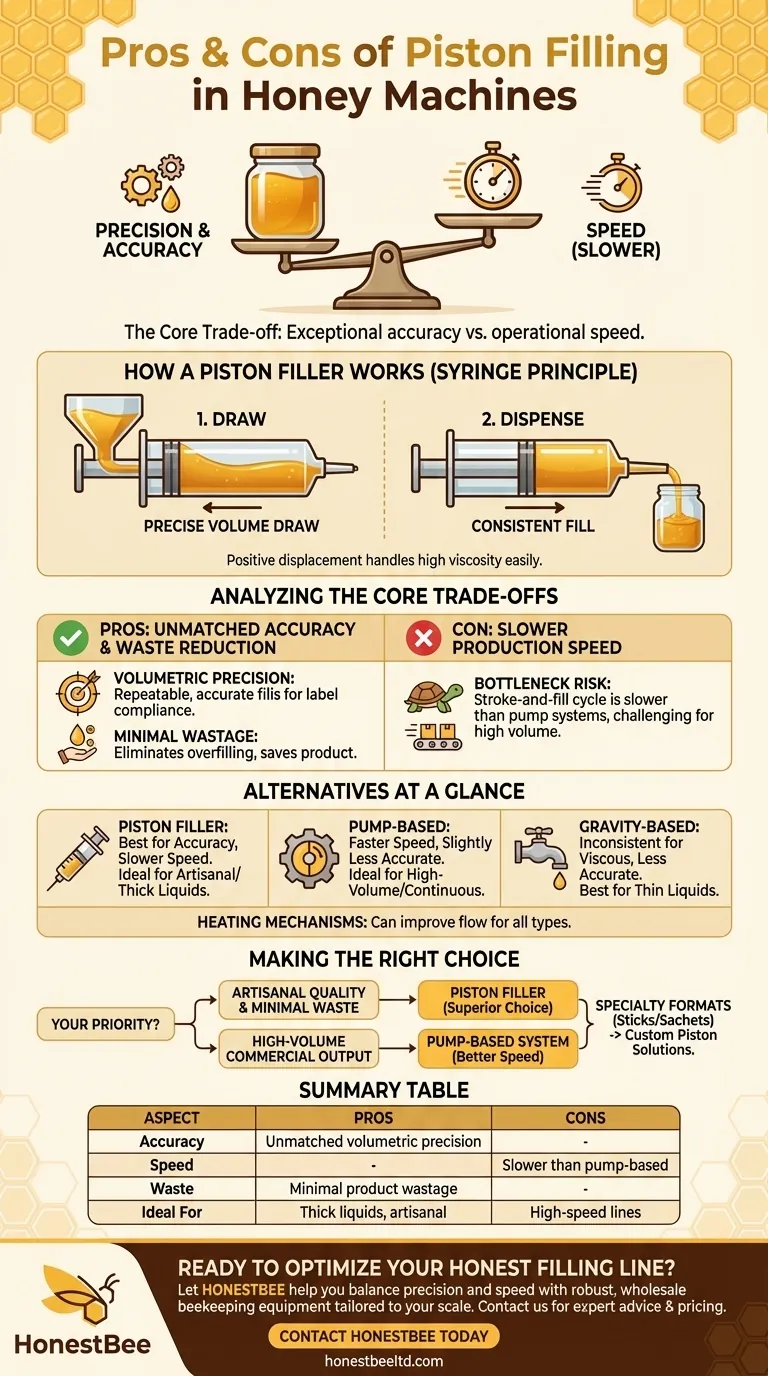

For honey producers, the core advantage of a piston filler is its exceptional accuracy with thick liquids, making it ideal for ensuring consistent volume and minimizing waste. Its primary disadvantage is a slower operational speed, which can be a bottleneck for high-volume commercial production lines. This trade-off between precision and speed is the central factor in choosing the right filling technology.

Piston fillers are the gold standard for accuracy and consistency when handling viscous products like honey. The fundamental choice is not about which system is "best," but which trade-off—precision at a slower pace versus speed with potentially less accuracy—best aligns with your business goals.

The Core Principle: How a Piston Filler Works

A piston filling machine operates on a simple, highly effective mechanical principle, making it uniquely suited for the challenges of handling honey.

The Syringe-Like Mechanism

Think of a piston filler as a large, automated medical syringe. In each cycle, a piston retracts within a cylinder, drawing a precise, predetermined volume of honey into the chamber directly from a hopper.

The piston then moves forward, dispensing that exact amount of honey through a nozzle and into the container. This volumetric action ensures each jar receives the same quantity.

Why It Excels with Viscous Liquids

Honey's high viscosity makes it difficult to manage with systems that rely on gravity or gentler pumps. The strong, positive displacement action of a piston easily pulls in and pushes out the thick liquid without compromising the fill volume.

This process ensures that changes in honey temperature or viscosity have a minimal impact on the final filled amount, guaranteeing consistency from the first jar to the last.

Analyzing the Core Trade-offs

Choosing a piston filler involves weighing its distinct benefits against its operational limitations.

Pro: Unmatched Filling Accuracy

The primary strength of a piston filler is its volumetric precision. Because it dispenses a specific, measured quantity with each stroke, it provides highly repeatable and accurate fills. This is critical for meeting label weight requirements and building consumer trust.

Pro: Consistency and Waste Reduction

This high accuracy directly translates to minimal product wastage. Overfilling is virtually eliminated, saving valuable product over thousands of cycles. It also ensures a consistent product appearance and experience for the customer.

Con: Slower Production Speed

The mechanical nature of the piston's stroke-and-fill cycle is inherently slower than continuous-flow methods like pump fillers. For small-scale or artisanal producers, this is often a non-issue. For large operations needing to fill thousands of jars per hour, it can become a significant bottleneck.

How Piston Fillers Compare to Alternatives

Understanding the other common filling technologies provides essential context for making an informed decision.

Pump-Based Fillers

Pump-based systems move honey through the filling nozzle using a gear or lobe pump. They are generally faster than piston fillers and well-suited for high-speed, continuous production lines. However, they may offer slightly less pinpoint accuracy per fill compared to a piston system.

Gravity-Based Fillers

Gravity fillers are simpler and work best for thin, low-viscosity liquids. While they can be adapted for honey, they are generally less efficient and accurate for such a thick product. The flow rate can be inconsistent, making them a less common choice for professional honey packing.

The Role of Heating Mechanisms

Many filling machines, regardless of type, can be equipped with heating elements in the hopper or lines. Gently warming the honey reduces its viscosity, allowing it to flow more smoothly. This can help improve speed and accuracy, especially for piston fillers, by ensuring an easier draw into the cylinder.

Making the Right Choice for Your Production

Your ideal filling system depends entirely on your operational priorities and scale.

- If your primary focus is artisanal quality and minimizing waste: A piston filler is the superior choice for its unmatched precision and consistency, especially for premium or small-batch honey.

- If your primary focus is high-volume commercial output: A pump-based system will likely provide the speed and throughput necessary to meet your production demands.

- If you are packaging honey in various formats like sticks or sachets: Custom piston filling solutions are often designed to handle these smaller, highly precise packaging requirements effectively.

Ultimately, understanding these core trade-offs empowers you to select the filling technology that aligns perfectly with your production goals.

Summary Table:

| Aspect | Pros of Piston Fillers | Cons of Piston Fillers |

|---|---|---|

| Accuracy | Unmatched volumetric precision for consistent fills | - |

| Speed | - | Slower than pump-based systems, a bottleneck for high volume |

| Waste | Minimal product wastage due to precise dispensing | - |

| Ideal For | Thick, viscous liquids like honey; artisanal/small-batch production | Less suitable for high-speed, continuous commercial lines |

Ready to Optimize Your Honey Filling Line?

As a commercial beekeeper or distributor, achieving the perfect balance between precision and speed is key to your profitability. HONESTBEE specializes in supplying robust, wholesale-focused beekeeping equipment, including honey filling machines tailored to your scale.

Let us help you select the right technology—whether a precision piston filler for consistent batches or a high-speed alternative for volume production—to minimize waste and maximize efficiency.

Contact HONESTBEE today for expert advice and wholesale pricing on equipment that supports your growth.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- Why is an industrial honey-filling machine critical for commercial-scale production? Scalability & Precision Explained

- How does industrial honey filling and processing equipment contribute to economic value? Maximize Pollination Profits

- What role do industrial filling and sealing machines play in honey export? Transform Raw Honey into Global Commodities

- How does honey filling and packaging equipment contribute to the commercialization of bee products? Scaling Your Success

- Why is the use of professional filling and sealing packaging machinery necessary for the production of high-value honey?

- What benefits do industrial automated filling machines provide for honey? Scale Your Production with Precision

- What are the differences between semi-automatic and fully automatic honey filling machines? A Guide to Choosing the Right Machine for Your Apiary

- How are filling machines calibrated to ensure accurate filling? Optimize Your Production Line for Maximum Profitability