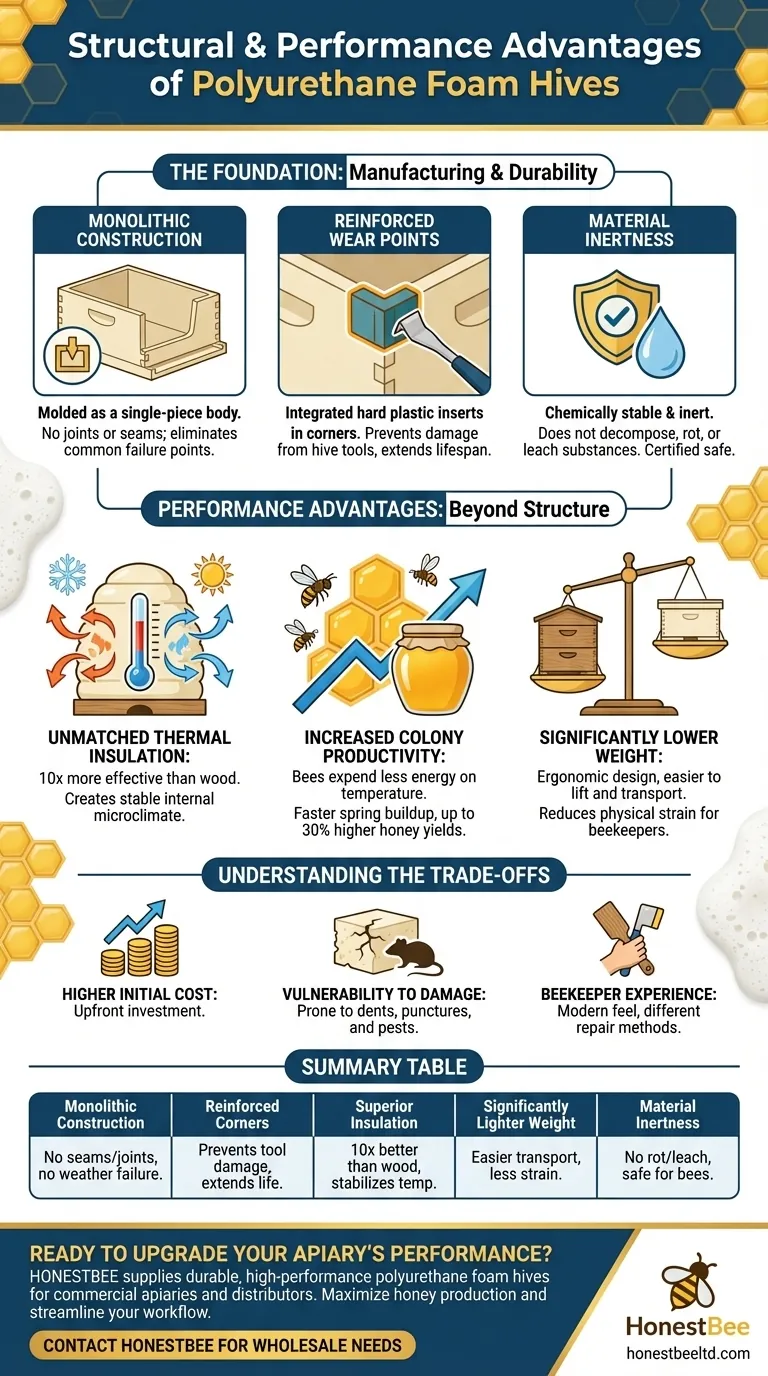

From a structural standpoint, polyurethane foam hives offer a unique combination of modern manufacturing and practical design enhancements. Their primary advantages are a monolithic (single-piece) molded construction for reliability, integrated plastic reinforcements at corners to prevent damage from tools, and a significantly lower weight compared to traditional wood.

While the specific structural features provide durability, the core advantage of polyurethane hives is how the material's properties—namely superior thermal insulation and light weight—translate into a system that can increase honey production and is far easier for the beekeeper to manage.

The Foundation: Manufacturing and Durability

The structural integrity of a polyurethane hive begins with how it is made. Unlike wooden hives assembled from multiple pieces, these are created as a single, cohesive unit.

Monolithic Construction

Polyurethane hives are manufactured in professional molds, resulting in a monolithic, or single-piece, body. This eliminates the joints and seams found in wooden hives, which are often the first points of failure due to weather and wear. This seamless design ensures consistent strength and reliability across the entire structure.

Reinforced Wear Points

A common frustration for beekeepers is damaging the edges of hive bodies with their scraper or hive tool. Polyurethane hives directly address this by embedding hard plastic inserts into the corners and top edges. This reinforcement allows for the safe and repeated use of beekeeping tools without gouging or damaging the softer foam material, dramatically extending the hive's functional lifespan.

Material Inertness

The polyurethane foam used is a chemically stable and inert material. It does not decompose, rot, or leach substances into the hive environment, which is confirmed by hygienic certifications. This ensures the structure remains sound over time and is completely safe for the bee colony.

Performance Advantages Beyond Structure

The material properties of polyurethane are what elevate its structural design into a high-performance beekeeping tool. The benefits extend directly to bee health and the beekeeper's workflow.

Unmatched Thermal Insulation

Polyurethane has exceptional thermal insulation properties, often cited as being ten times more effective than wood. This creates a more stable internal microclimate. The hive stays cooler during intense summer heat and, more critically, retains warmth far better during winter.

Increased Colony Productivity

Because the hive is so well-insulated, the bees expend significantly less energy maintaining the required brood nest temperature (around 95°F/35°C). This conserved energy is reallocated to other tasks. Colonies in polyurethane hives often build up faster in the spring and can dedicate more resources to foraging, which can lead to honey yields up to 30% higher than in traditional hives.

The Benefit of Low Weight

A major practical advantage is the material's light weight. Polyurethane hive components are significantly lighter than their wooden counterparts, making them more ergonomic to lift and transport. This is a crucial benefit for beekeepers with physical limitations, large apiaries requiring frequent inspection, or those operating mobile (nomadic) apiaries.

Understanding the Trade-offs

No material is perfect, and an objective assessment requires looking at potential downsides. While polyurethane offers clear performance benefits, there are trade-offs to consider compared to traditional wood.

Initial Cost

Molded polyurethane hives typically have a higher upfront purchase price than standard wooden hive components. This initial investment must be weighed against the long-term gains in productivity and hive longevity.

Susceptibility to Physical Damage

While corners are reinforced against tools, the foam body itself can be dented or punctured by sharp impacts. It is also more vulnerable to pests like mice or wax moths, which may find it easier to chew through foam than solid wood if they gain access.

The Beekeeper's Experience

Some beekeepers simply prefer the feel, tradition, and repairability of wood. Polyurethane is a modern material that handles differently and cannot be modified or repaired with the same simple carpentry tools one might use on a wooden hive.

Making the Right Choice for Your Apiary

The decision to use polyurethane hives should be based on your specific goals and management style.

- If your primary focus is maximizing honey production and winter survival: The superior thermal performance of polyurethane offers a clear and measurable advantage.

- If your primary focus is ease of management and mobility: The lightweight, ergonomic design significantly reduces the physical strain of beekeeping, especially at a larger scale.

- If your primary focus is lowest initial cost and traditional methods: Standard wooden hives remain a viable, lower-cost entry point, though they lack the inherent thermal efficiency of foam.

Ultimately, choosing a hive material is about aligning its specific performance characteristics with your beekeeping goals and operational needs.

Summary Table:

| Structural Advantage | Key Benefit for Beekeepers |

|---|---|

| Monolithic Construction | No seams or joints; eliminates points of failure from weather and wear. |

| Reinforced Corners | Hard plastic inserts prevent damage from hive tools, extending lifespan. |

| Superior Insulation | 10x better than wood; stabilizes hive temperature for faster spring buildup. |

| Significantly Lighter Weight | Easier to lift and transport, reducing physical strain. |

| Material Inertness | Does not rot or leach; safe for bees and hygienically certified. |

Ready to upgrade your apiary's performance?

HONESTBEE supplies durable, high-performance polyurethane foam hives and beekeeping equipment to commercial apiaries and distributors through our wholesale-focused operations. Our hives are engineered to help you maximize honey production and streamline your workflow.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can strengthen your operation.

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Professional Drop-Style Hive Handles for Beekeeping

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- Heavy Duty Ratchet Hive Strap

People Also Ask

- What is the advantage of using cam buckle straps? Secure Your Load Fast with Simple, Safe Tensioning

- What are the types of Emlocks available? Choose the Right Strap for Hive Security

- What is the best length for straps used around beehives? Why 12 Feet is the Industry Standard

- What maintenance is required for hive straps? A Guide to Cam Buckle vs. Ratchet Strap Care

- What are the two styles of hive straps? Choose the Right Strap for Your Hive Security