At its core, a wax melter is a specialized device used to heat solid wax into a liquid state. These tools are essential in industries ranging from candle making and beekeeping to industrial packaging. They provide a controlled environment to transform raw materials like beeswax honeycombs or paraffin blocks into a usable, pourable liquid.

A wax melter’s primary function is to apply controlled heat, allowing you to melt, filter, and mold wax for a specific purpose. The type of melter you choose depends on your energy source, the volume of wax you need to process, and your desired final quality.

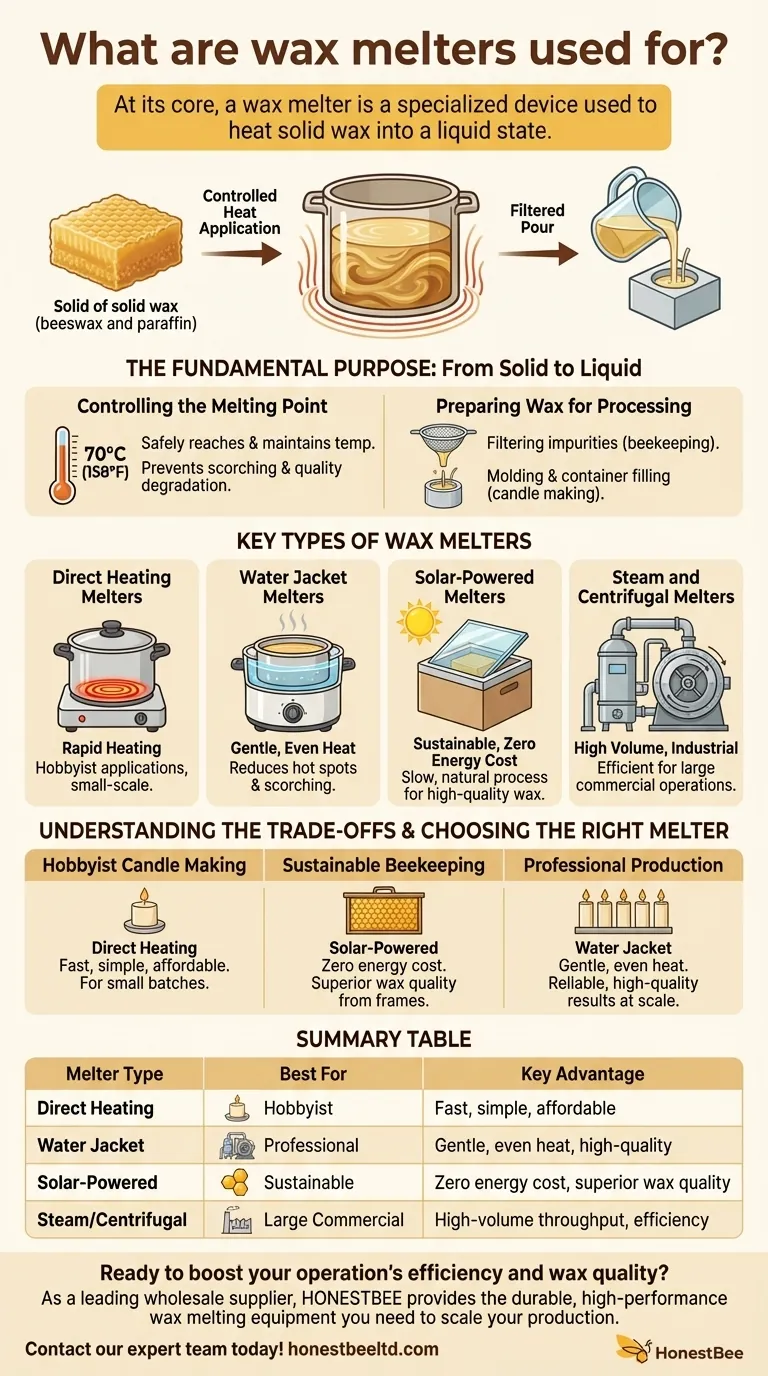

The Fundamental Purpose: From Solid to Liquid

A wax melter manages the critical phase transition of wax. It's not just about applying heat, but about applying it correctly to achieve a clean and usable product.

Controlling the Melting Point

Different types of wax have specific melting points. For example, beeswax and paraffin begin to melt at temperatures above +70°C (158°F). A wax melter is engineered to safely reach and maintain this temperature without scorching the wax, which can degrade its quality and color.

Preparing Wax for Processing

Once melted, the liquid wax is ready for the next step. In beekeeping, this often involves filtering the liquid wax from used honeycombs to remove impurities. For candle making, the clean, liquid wax is then poured into molds or containers with a wick.

Key Types of Wax Melters

Wax melters are classified by their heating method and energy source. The design you choose directly impacts efficiency, scale, and cost.

Direct Heating Melters

These are the most straightforward type, often resembling an electric pot. A heating element is in direct contact with the container holding the wax, providing rapid heating. They are common for small-scale hobbyist applications.

Water Jacket Melters

These melters operate like a double boiler. The wax container is surrounded by a separate chamber filled with water, which is then heated. This method provides more gentle, even heat distribution, reducing the risk of hot spots and scorching the wax.

Solar-Powered Melters

A popular choice in beekeeping, a solar melter is an insulated box with a glass lid that uses the sun's energy to melt wax. This sustainable method produces very high-quality wax due to its slow, natural melting process. It is ideal for processing raw honeycombs.

Steam and Centrifugal Melters

These are typically larger, more industrial machines. Steam plants use steam to melt large quantities of wax efficiently, while centrifugal machines use heated rotation to separate wax from impurities. Both are suited for large commercial operations.

Understanding the Trade-offs

Choosing a wax melter involves balancing cost, convenience, and the quality of the final product. No single type is best for every situation.

Energy Source and Footprint

Electric melters offer consistent, on-demand heat but contribute to your energy bill. Solar melters are exceptionally sustainable and have no running costs but are entirely dependent on clear, sunny weather to function.

Scale of Operation

A small direct-heat pot is perfect for a hobbyist making a few candles. A beekeeper with many hives will benefit from the larger capacity of a solar melter. Commercial producers require the high throughput of steam or water jacket systems.

Final Wax Quality

Slower, more gentle heating methods tend to produce a cleaner, higher-quality final product. Solar and water jacket melters excel here, as they minimize the risk of darkening or burning the wax, preserving its natural color and scent.

Choosing the Right Melter for Your Goal

Your specific application will determine the ideal tool for the job. Consider your primary objective when making a selection.

- If your primary focus is hobbyist candle making: A simple and affordable electric direct-heating pot offers the control and speed you need for small batches.

- If your primary focus is sustainable beekeeping: A solar wax melter is an excellent choice for producing high-quality beeswax from your frames with zero energy cost.

- If your primary focus is consistent, professional production: A water jacket melter provides the even heat and reliable performance needed for high-quality, repeatable results at scale.

Ultimately, selecting the right wax melter empowers you to transform a raw material into a refined, valuable product with efficiency and control.

Summary Table:

| Melter Type | Best For | Key Advantage |

|---|---|---|

| Direct Heating | Hobbyist Candle Making | Fast, simple, and affordable |

| Water Jacket | Professional Production | Gentle, even heat for high-quality results |

| Solar-Powered | Sustainable Beekeeping | Zero energy cost, superior wax quality |

| Steam/Centrifugal | Large Commercial Operations | High-volume throughput and efficiency |

Ready to boost your operation's efficiency and wax quality? As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance wax melting equipment you need to scale your production. Our solutions are designed for reliability and consistent results. Contact our expert team today to discuss your specific requirements and get a tailored quote!

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting