The primary machine used for extracting honey is called a honey extractor. This device uses centrifugal force to pull honey from the cells of the honeycomb without destroying the delicate wax structure. Because the comb remains intact, it can be returned to the hive for the bees to refill, saving them a tremendous amount of time and energy.

A honey extractor is the centerpiece of the honey harvesting process. It works by spinning uncapped frames, slinging the honey out against the walls of a drum where it can be collected. The real challenge, however, lies in understanding the full process and equipment that surround this single, crucial step.

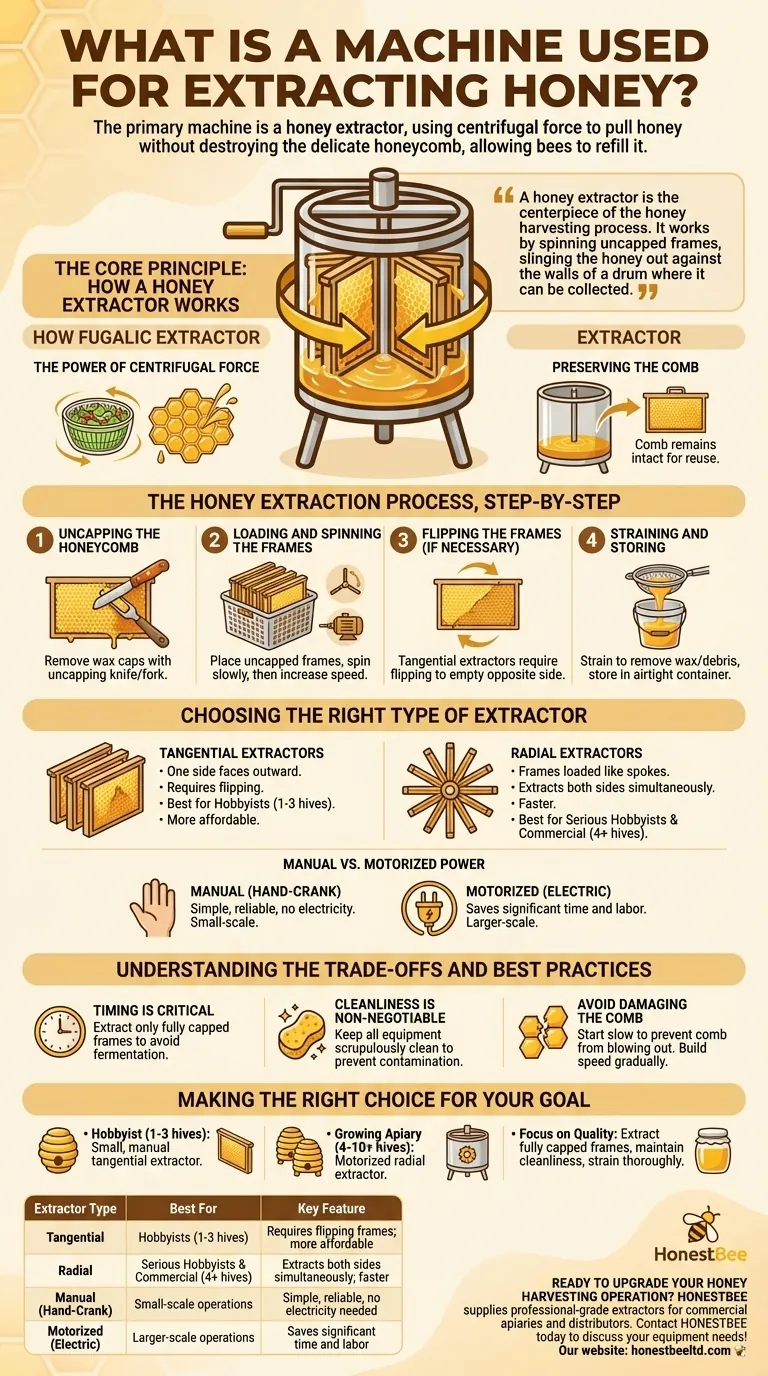

The Core Principle: How a Honey Extractor Works

A honey extractor is fundamentally a simple machine, but its design is key to modern beekeeping. It allows for a repeatable, non-destructive harvest.

The Power of Centrifugal Force

An extractor operates much like a salad spinner. As the frames spin inside the drum, the force generated pushes the liquid honey outward and away from the center, flinging it from the open cells onto the interior wall of the extractor.

Preserving the Comb

The honey flows down the extractor's wall and pools at the bottom, where it can be drained through a valve or "honey gate." The most significant advantage of this method is that the honeycomb itself is not crushed or destroyed, a stark contrast to older press-based methods.

The Honey Extraction Process, Step-by-Step

The extractor is just one tool in a multi-step workflow. A successful harvest requires preparing the frames properly and handling the honey correctly after extraction.

Step 1: Uncapping the Honeycomb

Bees seal each cell of finished honey with a fresh wax cap. Before extraction, these caps must be carefully removed. This is typically done with a specialized uncapping knife (which can be heated or cold), a cappings scratcher, or a fork.

Step 2: Loading and Spinning the Frames

The uncapped frames are placed into baskets or slots inside the extractor. The operator then begins spinning the frames, either with a manual hand-crank or an electric motor. It's best to start slowly and gradually increase the speed to avoid damaging the comb with the initial weight of the honey.

Step 3: Flipping the Frames (If Necessary)

Depending on the type of extractor, you may need to stop, flip the frames to face the opposite direction, and spin again to empty the other side of the comb.

Step 4: Straining and Storing

The raw honey collected from the extractor will contain small bits of wax and other debris. It must be strained, often through mesh filters or cheesecloth, before it is ready for bottling. The honey is then typically stored in a clean, airtight 5-gallon bucket or bottling tank.

Choosing the Right Type of Extractor

Honey extractors come in two primary designs, with both available in manual or motorized versions. The right choice depends entirely on the scale of your beekeeping operation.

Tangential Extractors

In a tangential extractor, the frames are positioned so that one side of the comb faces outward. This design requires you to spin one side, stop the machine, flip each frame, and then spin the second side. They are generally more affordable and are an excellent choice for hobbyists.

Radial Extractors

In a radial extractor, frames are loaded like the spokes of a wheel, with the top bar facing outward. Centrifugal force extracts honey from both sides of the comb simultaneously, making the process much faster and eliminating the need to flip frames. These are preferred by serious hobbyists and commercial beekeepers.

Manual vs. Motorized Power

Manual, hand-crank extractors are simple, reliable, and do not require electricity. They are perfect for those with only a few hives. Motorized extractors use an electric motor to do the spinning, dramatically reducing physical effort and saving significant time for anyone managing several hives.

Understanding the Trade-offs and Best Practices

Simply owning an extractor doesn't guarantee a perfect harvest. Avoiding common mistakes is crucial for ensuring high-quality honey and a healthy hive.

Timing is Critical

Only extract honey from frames where the majority of cells are capped. Uncapped honey has a higher moisture content, which can cause the entire batch to ferment and spoil during storage.

Cleanliness is Non-Negotiable

All equipment, from the uncapping knife to the storage buckets, must be scrupulously clean. Any contamination can ruin the flavor and quality of the honey.

Avoid Damaging the Comb

Spinning the extractor too fast, especially at the very beginning when the frames are at their heaviest, can cause the wax comb to blow out or break apart within the frame. Always start slow and build speed gradually.

Making the Right Choice for Your Goal

Selecting the right equipment is about matching the tool to the task.

- If you are a hobbyist with 1-3 hives: A small, manual tangential extractor is the most cost-effective and practical choice for your needs.

- If you manage a growing apiary of 4-10+ hives: A motorized radial extractor is a worthwhile investment that will save you a massive amount of time and labor.

- If your primary focus is maximizing honey quality: Ensure you only extract fully capped frames, maintain impeccable cleanliness, and strain your honey thoroughly before bottling.

Understanding the complete extraction process is the key to a successful, sustainable, and rewarding honey harvest.

Summary Table:

| Extractor Type | Best For | Key Feature |

|---|---|---|

| Tangential | Hobbyists (1-3 hives) | Requires flipping frames; more affordable |

| Radial | Serious Hobbyists & Commercial (4+ hives) | Extracts both sides simultaneously; faster |

| Manual (Hand-Crank) | Small-scale operations | Simple, reliable, no electricity needed |

| Motorized (Electric) | Larger-scale operations | Saves significant time and labor |

Ready to upgrade your honey harvesting operation?

Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the professional-grade extractors and harvesting equipment you need to maximize efficiency and honey quality. Our wholesale-focused operations ensure you get the right tools for your scale.

Contact HONESTBEE today to discuss your equipment needs and streamline your harvest!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Professional Stainless Steel Honey Filtering Machine with Water Bath Heating for Beekeeping

People Also Ask

- What are the advantages of using automated honey filling equipment? Scaling Your Commercial Honey Production

- What is the value of honey filling and packaging machinery? Accelerate Commercial Scalability and Global Market Access

- How do industrial honey filling machines protect the biological activity of honey? Ensure Nutritional Integrity

- What is the significance of automated honey-filling machinery? Protect Your Harvest from Small Hive Beetle Spoilage

- What is the role of Automated Honey-filling Machines? Scale Your Honey Brand with Precision and Safety