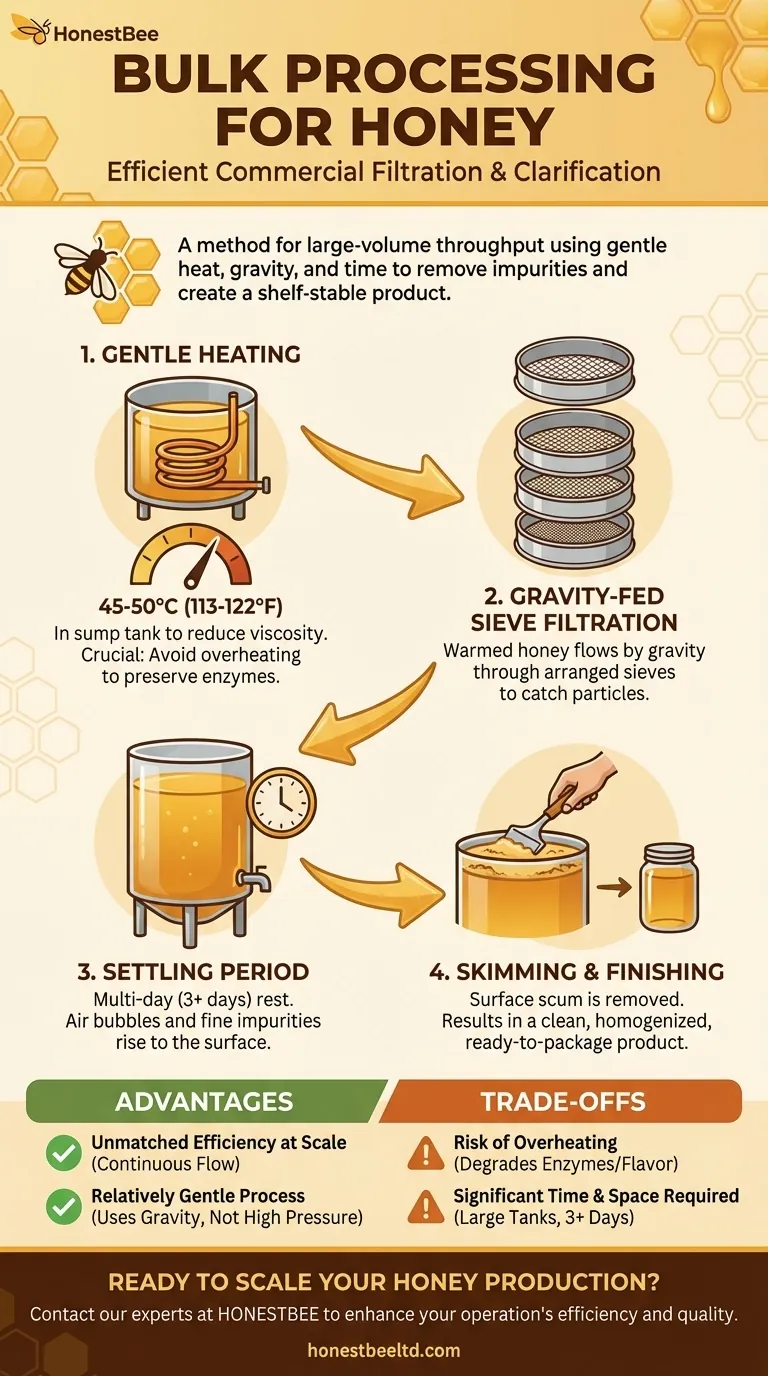

Bulk processing for honey is a specific filtration and clarification method designed to handle large commercial quantities efficiently. It uses a combination of gentle heat to reduce viscosity, followed by a gravity-fed flow through a series of concentric sieves and a multi-day settling period to remove impurities like wax and air bubbles.

The core purpose of bulk processing is to bridge the gap between raw, extracted honey and a commercially shelf-stable product. It systematizes filtration for large volumes by using gentle heat, gravity, and time, rather than high-pressure force, to clarify the honey while aiming to preserve its essential qualities.

The Context: From Raw Honey to a Finished Product

Before a specific method like bulk processing is used, honey must go through a few universal steps. Understanding this broader context shows why specialized techniques are necessary for large-scale operations.

Initial Extraction

The process begins at the honeycomb. An extractor, which is a large centrifuge, spins the frames at high speed. This force pulls the liquid honey out of the wax cells without destroying the comb.

The Filtration Imperative

After extraction, the raw honey contains various particles, including bits of beeswax, pollen, and microscopic air bubbles. Filtration is necessary to create the clear, smooth product consumers expect and to improve its shelf life by removing particles that can trigger crystallization.

A Step-by-Step Look at Bulk Processing

Bulk processing is a systematic approach to the filtration challenge. It is not a single action but a multi-stage workflow designed for continuous, large-volume throughput.

Stage 1: Gentle Heating in a Sump Tank

The semi-refined honey is first held in a large container called a sump tank. Here, it is gently heated to between 45-50°C (113-122°F). This step is critical; it lowers the honey's viscosity, making it flow more easily without "cooking" it or destroying its delicate enzymes and aromas.

Stage 2: Gravity-Fed Sieve Filtration

From the sump tank, the warmed honey flows by gravity through a series of sieves. These are cleverly arranged concentrically, with the coarsest mesh on the inside and the finest on the outside. This design allows larger particles to be caught first, preventing the finer sieves from clogging quickly.

Stage 3: The Crucial Settling Period

After passing through the sieves, the honey enters a large settling tank. It is left undisturbed here for at least three days. This extended period allows natural forces to do the final clarification work. Lighter impurities, such as fine wax particles and air bubbles churned in during extraction, slowly rise to the surface.

Stage 4: Skimming and Final Packaging

Once the settling period is complete, a layer of "scum" will have formed on the surface of the honey. This is carefully skimmed off, leaving behind a clean, clarified final product. The honey is then ready to be homogenized for consistency and packaged.

Understanding the Trade-offs

Like any industrial process, bulk processing involves a balance of benefits and potential downsides that are important to manage.

Advantage: Unmatched Efficiency at Scale

The primary benefit is its ability to process enormous quantities of honey in a continuous flow. It is a system built for commercial output, far exceeding what manual or small-batch methods could handle.

Advantage: A Relatively Gentle Process

Despite the use of heat, the reliance on gravity instead of high-pressure pumps is a key advantage. High pressure can damage the honey, so this gentle, slow-moving method helps preserve its natural quality.

Risk: The Danger of Overheating

The heating stage is the most sensitive part of the process. If the temperature exceeds the recommended range, there is a significant risk of degrading the honey's natural enzymes (like diastase and invertase) and altering its flavor and color. Precise temperature control is non-negotiable.

Limitation: Time and Space Requirements

The mandatory three-day settling period is a major operational factor. This requires significant investment in large settling tanks and the physical space to house them, making the method impractical for smaller or space-constrained operations.

Making the Right Choice for Your Goal

To determine if this method fits your needs, consider the scale and priorities of your operation.

- If your primary focus is large-scale commercial production: Bulk processing provides an efficient, reliable, and systematic way to clarify large volumes of honey for a consistent final product.

- If your primary focus is small-batch or artisanal honey: The equipment, space, and time demands of bulk processing are unnecessary; simpler straining and settling techniques are more appropriate.

- If your primary focus is preserving raw honey characteristics: You must implement extremely precise temperature controls during the heating phase to ensure you do not compromise the honey's natural enzymes and delicate profile.

Ultimately, bulk processing is an industrial solution engineered to produce clean, stable honey at a scale that simple straining cannot match.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Heating | Gentle warming to 45-50°C (113-122°F) in a sump tank | Reduces viscosity for easier flow without damaging honey. |

| 2. Filtration | Gravity-fed flow through concentric sieves | Removes wax and other particles efficiently. |

| 3. Settling | Multi-day (3+ days) rest in a settling tank | Allows air bubbles and fine impurities to rise. |

| 4. Finishing | Skimming and packaging | Produces a clean, stable, final product. |

Ready to Scale Your Honey Production with Reliable Equipment?

For commercial apiaries and beekeeping equipment distributors, efficient bulk processing is key to profitability and product quality. HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and equipment you need to build or optimize your large-scale honey clarification system—from sump tanks to settling tanks.

Contact our experts today to discuss your specific needs and discover how our solutions can enhance your operation's efficiency and honey quality.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How does a double sieve honey strainer work? Achieve Crystal Clear Honey with Professional Two-Stage Filtration

- What is the function of honey sieves, strainers, and filters in processing? Master the 3 Stages of Honey Purity

- What is the overall importance of using the right equipment in honey filtering? Boost Quality & Marketability

- Should honey be filtered or unfiltered? Maximize Health Benefits with Raw Honey

- Why is filtering important in honey processing, and what equipment is used? A Guide to Quality & Efficiency