At their core, the regular inspection requirements for both Flow Hives and standard Langstroth hives are fundamentally the same. Both systems demand that the beekeeper opens the hive, removes frames from the brood box, and thoroughly checks for pests, diseases, and the overall health of the colony. The innovation of the Flow Hive relates only to honey harvesting, not to the essential duties of hive management.

The central takeaway is that the choice between a Flow Hive and a Langstroth hive affects the honey harvesting process, not the non-negotiable responsibility of regular, hands-on colony inspections. Successful beekeeping in either system depends on the same fundamental skills.

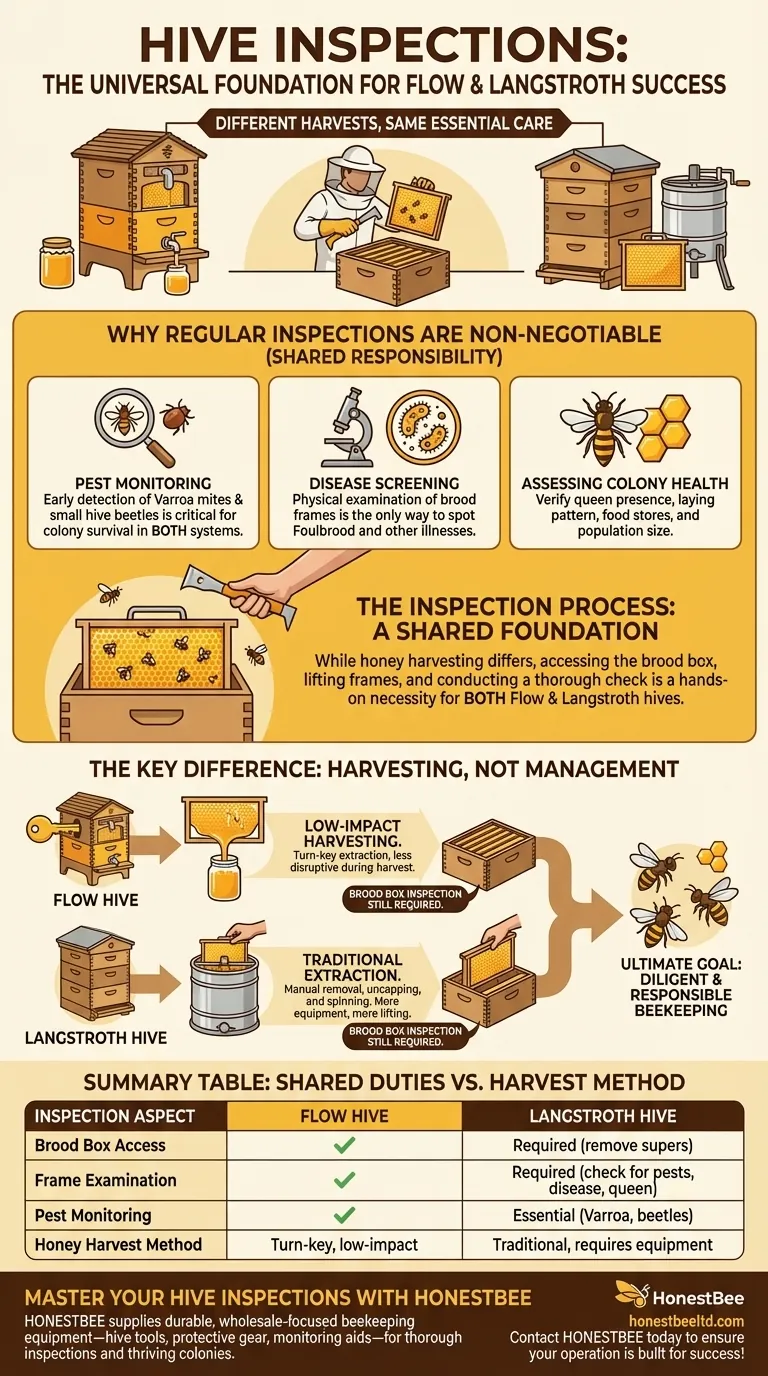

Why Regular Inspections Are Non-Negotiable

A beehive is a living superorganism that faces constant threats. The type of box it lives in does not change this reality. Regular inspections are your primary tool for ensuring its survival and productivity.

Monitoring for Pests

The two most significant pests, Varroa mites and small hive beetles, can devastate a colony. Inspections are critical for early detection and treatment, regardless of whether you use a Flow Hive or a Langstroth.

Screening for Disease

Diseases like American and European Foulbrood can spread rapidly and are a serious threat to your bees and surrounding colonies. Only by physically examining the brood frames can you spot the tell-tale signs of these and other illnesses.

Assessing Colony and Queen Health

Inspections allow you to confirm the queen is present and laying a healthy, consistent brood pattern. You can also assess the colony's food stores (pollen and honey), population size, and general temperament, which are all vital signs of its health.

The Inspection Process: A Shared Foundation

The perception that a Flow Hive requires less work can be misleading. While honey harvesting is simpler, the process of a full hive inspection is nearly identical to that of a Langstroth hive.

Accessing the Brood Box

In both systems, the colony's nursery, or brood box, is typically the bottom-most box. To inspect it, you must still remove the upper boxes (honey supers), which can be heavy. The physical effort to access the most important part of the hive is the same.

Examining the Frames

Both the Flow Hive and Langstroth hive use standard frame designs in the brood box. You must use a hive tool to pry frames apart, lift them out individually, and carefully examine both sides for the health indicators mentioned above. This is a delicate, hands-on process in either hive.

Understanding the Trade-offs: Harvesting vs. Management

The key difference between the two systems is not one of overall management but of convenience and philosophy during the honey harvest.

The Flow Hive Advantage: Low-Impact Harvesting

The primary innovation of the Flow Hive is its specialized frames in the honey super. By turning a key, you crack the plastic comb, allowing honey to drain out through a tube without removing the frames or disturbing the bees. This is less disruptive during the harvest itself.

The Langstroth Method: Traditional Extraction

With a Langstroth hive, you must physically remove the heavy honey-filled supers. The frames are then uncapped, and the honey is spun out using a centrifugal extractor. This process requires more equipment, creates more disruption for the bees, and involves more heavy lifting.

The Hidden Costs

The convenience of the Flow Hive comes at a significant financial cost, as the specialized frames are much more expensive. Conversely, while a Langstroth setup is cheaper initially, it may require a later investment in extraction equipment.

Making the Right Choice for Your Beekeeping Goals

Your decision should be based on your budget, physical ability, and beekeeping philosophy, not on a desire to avoid inspections.

- If your primary focus is harvesting convenience and minimizing disruption to the bees during harvest: The Flow Hive is a suitable choice, provided you are prepared for the higher initial cost and understand it does not eliminate regular management tasks.

- If your primary focus is cost-effectiveness, learning traditional methods, and having a modular system: The Langstroth hive is the time-tested global standard and an excellent, economical choice.

Ultimately, diligent and responsible beekeeping is the true key to success, regardless of the equipment you choose.

Summary Table:

| Inspection Aspect | Flow Hive | Langstroth Hive |

|---|---|---|

| Brood Box Access | Required (remove honey supers) | Required (remove honey supers) |

| Frame Examination | Required (check for pests, disease, queen) | Required (check for pests, disease, queen) |

| Pest Monitoring | Essential (Varroa mites, hive beetles) | Essential (Varroa mites, hive beetles) |

| Honey Harvest Method | Turn-key, low-impact extraction | Traditional, requires extraction equipment |

Ready to Master Your Hive Inspections?

Whether you manage a commercial apiary or are a beekeeping equipment distributor, proper hive maintenance is the foundation of success. HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and equipment you need—from hive tools and protective gear to monitoring aids—to perform thorough inspections and maintain thriving colonies.

Contact HONESTBEE today to discuss your equipment needs and ensure your beekeeping operation is built for success!

Visual Guide

Related Products

- HONESTBEE Premium Italian Style Hive Tool with Hardwood Handle

- HONESTBEE 15-in-1 Beekeeper Multi-Tool with Hammer and Pliers for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Versatile Ratchet Hive Strap with S-Hooks for Secure Fastening

People Also Ask

- Why is it important to prevent swarming in a bee colony? Maximize Your Hive's Productivity and Health

- What are the advantages of dual-sensor infrared coupling in bee counters? Achieve Precision Hive Monitoring

- What role does an Industrial Colorimeter play in honey grading? Master Professional Pfund Scale Standards

- What is the function of industrial-grade weighing equipment in winter bee colonies? Optimize Your Overwintering Success

- What is the strategic importance of equipping commercial stingless bee apiaries? Drive Industrial Modernization

- What role does a precision colorimeter or Pfund scale device play in the commercial grading of honey? Maximize Trade Value

- Can a beehive setup be expanded beyond a starter kit? Scale Your Apiary for Success

- How do specialized transport vehicles support the management of decentralized apiaries? Scaling Your Logistics Strategy