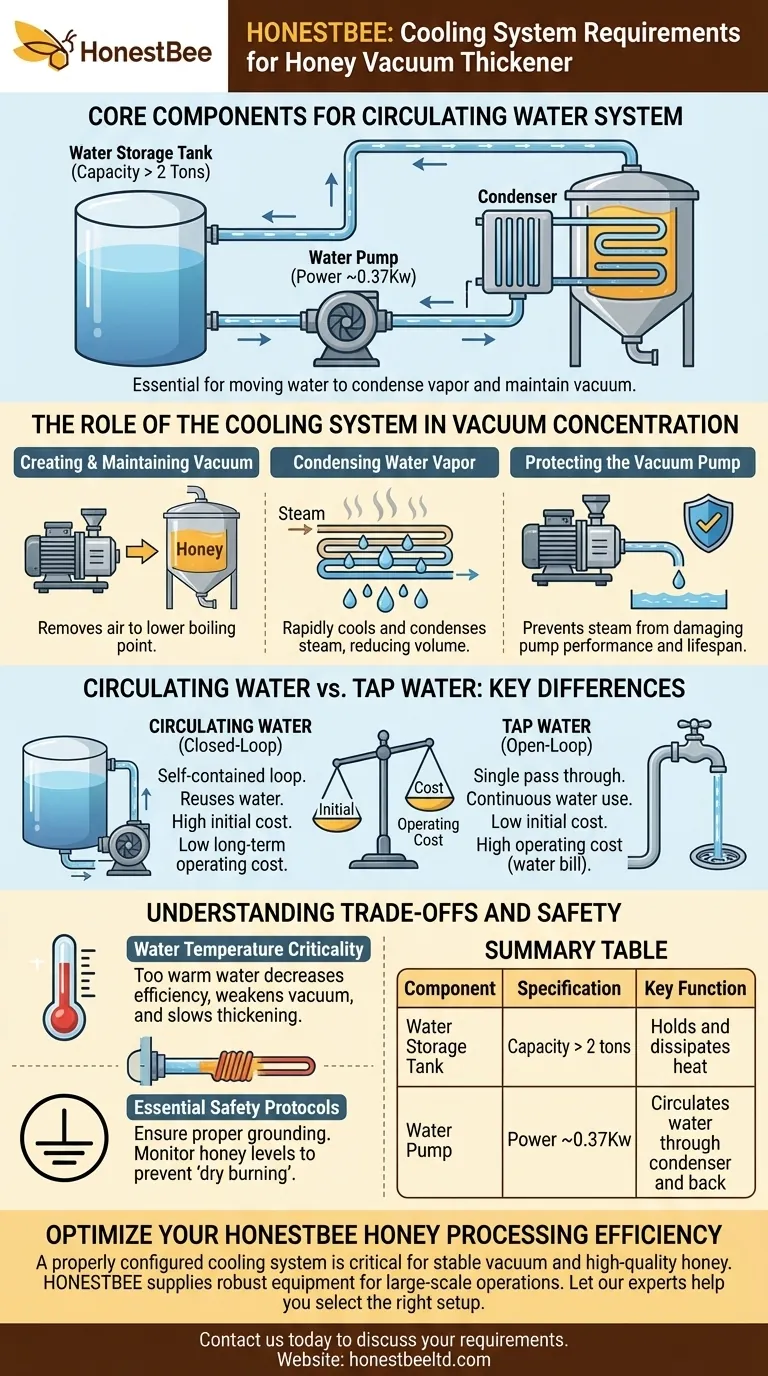

To operate a honey vacuum thickener with a circulating water cooling system, you must have two core components. The system requires a water storage tank with a capacity of more than 2 tons and a dedicated water pump with a power rating of approximately 0.37Kw to move the water from the tank, through the condenser, and back again.

The cooling system is not just an accessory; it is the engine of the entire vacuum process. Its primary function is to condense the water vapor removed from the honey, which is the critical step in creating and maintaining the low-pressure environment needed for efficient concentration.

The Role of the Cooling System in Vacuum Concentration

To understand the equipment requirements, we must first understand the physics at play. A vacuum thickener works by lowering the boiling point of water, allowing it to be removed from the honey without the damaging high heat of atmospheric boiling.

Creating and Maintaining the Vacuum

The vacuum pump's initial job is to remove air from the system. However, as the honey is heated, it releases a massive volume of water vapor (steam). The pump alone cannot handle this vapor volume efficiently.

Condensing Water Vapor

This is the central role of the cooling system. The circulating cool water flows through a condenser. As the hot water vapor from the honey passes over the cold surfaces of the condenser, it rapidly cools and turns back into liquid water, drastically reducing its volume.

Protecting the Vacuum Pump

This condensation process is essential for protecting the vacuum pump. If large amounts of hot water vapor were allowed to enter the pump, it could cause damage and would quickly degrade the pump's performance and lifespan.

Circulating Water vs. Tap Water: The Key Differences

The references highlight two main methods for supplying cooling water. Your choice has significant implications for both setup and operational costs.

The Circulating Water (Closed-Loop) System

This setup, requiring the 2+ ton tank and 0.37Kw pump, creates a self-contained loop. Water is pumped from the tank, cools the condenser, and the now-warmed water is returned to the tank where its heat can dissipate over time. This method conserves a massive amount of water.

The Tap Water (Open-Loop) Alternative

For this method, no tank or dedicated pump is needed. A standard tap water pipe is connected directly to the condenser's inlet. The water makes a single pass through the system and is then discharged directly into a sewer or drain. While simple to set up, this approach consumes a continuous and significant volume of water during operation.

Understanding the Trade-offs and Safety

Choosing and operating your cooling system correctly involves balancing costs and monitoring key performance indicators to ensure both efficiency and safety.

Initial Cost vs. Operating Cost

A circulating water system has a higher upfront investment due to the need for a large tank and a pump. However, its long-term operating costs are significantly lower because it reuses water, drastically reducing your water bill. A tap water system has almost no initial cost but incurs a continuous operating cost through high water consumption.

Water Temperature is Critical

During the concentration process, you must pay close attention to the temperature of the cooling water. If the water in your circulating tank becomes too warm, its ability to condense the steam efficiently will decrease. This leads to a weaker vacuum, slowing down the honey thickening process.

Essential Safety Protocols

Beyond the cooling water, always ensure the equipment's shell is properly grounded to prevent electrical hazards. Critically, monitor the honey levels in the preheating and concentration tanks to ensure the heating elements are always submerged, preventing a dangerous "dry burning" scenario.

Making the Right Choice for Your Operation

Your decision should be based on the scale and frequency of your honey processing operation.

- If your primary focus is minimizing long-term operating costs and water usage: A circulating water system with the specified 2-ton tank and 0.37Kw pump is the correct investment.

- If your primary focus is the lowest possible initial setup cost for infrequent use: A direct tap water connection is a viable starting point, but be prepared for high water consumption during runs.

- If your primary focus is process efficiency and consistency: The circulating water system offers better control over cooling temperature, which directly impacts the stability of your vacuum and the quality of your final product.

Properly configuring and managing your cooling system is the key to unlocking consistent, high-quality results from your vacuum thickener.

Summary Table:

| Component | Specification | Key Function |

|---|---|---|

| Water Storage Tank | Capacity > 2 tons | Holds and dissipates heat from the cooling water |

| Water Pump | Power ~0.37Kw | Circulates water from the tank, through the condenser, and back |

Optimize Your Honey Processing Efficiency with HONESTBEE

A properly configured cooling system is critical for maintaining a stable vacuum, protecting your equipment, and producing high-quality honey. HONESTBEE supplies the robust beekeeping supplies and equipment—like the essential components for your vacuum thickener—that commercial apiaries and distributors rely on for efficient, large-scale operations.

Let our experts help you select the right setup for your needs. Contact us today to discuss your requirements and ensure your honey concentration process runs smoothly and cost-effectively.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How do professional Honey Filtration and Processing Equipment contribute to the purity and market grading? Boost Quality

- What role does an industrial grinding machine play in propolis processing? Boost Extraction & Product Quality

- What role does a high-speed centrifuge play in the preliminary processing of raw honey? Enhancing Purity and Clarity

- What technical benefits do industrial-grade electric vacuum suction machines provide? Boost Royal Jelly Harvest Efficiency

- What are the benefits of using a Honey Processing Machine? Boost Quality & Scale Your Apiary

- What equipment is commonly used for heating and processing honey? Essential Tools for Every Beekeeper

- Why is professional Honey Processing Equipment necessary for commercialization? Scale Your Business with Quality Tools

- Why is the use of high-grade stainless steel mandatory for honey equipment? Protect Purity and Ensure Food Safety