At its core, a Weighing Filling Machine is a specialized piece of equipment designed to dispense a precise and consistent weight of a product into containers like jars, bags, or bottles. Using an integrated scale, it actively measures the product as it's being filled and stops the flow exactly when the target weight is reached, ensuring exceptional accuracy for every package.

The true purpose of a weighing filling machine is not just to fill containers, but to eliminate the costly variables of product giveaway and inconsistency. It replaces volume-based estimation with weight-based certainty, protecting profit margins and ensuring commercial compliance.

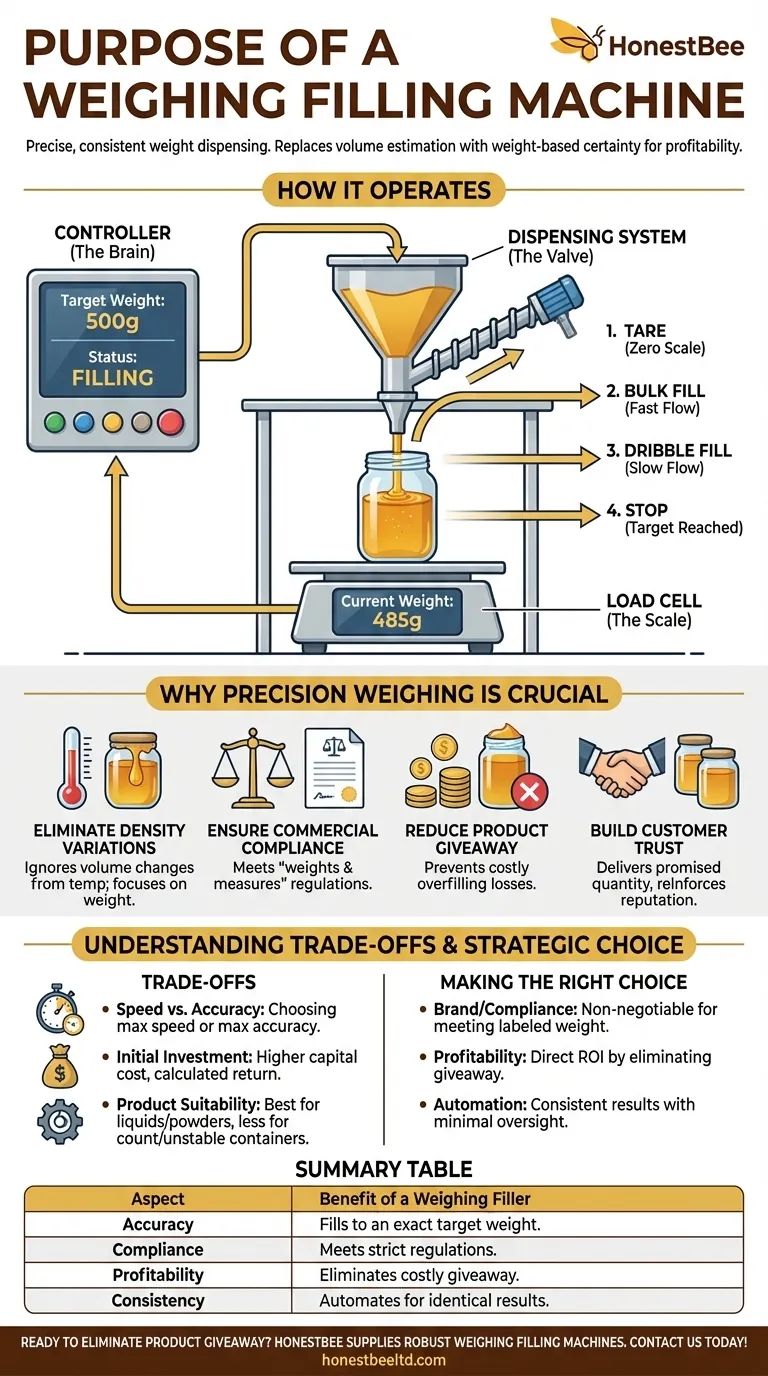

How a Weighing Filling Machine Operates

To understand its value, you must first understand its mechanism. The machine combines a dispensing system with a highly sensitive weighing system, all managed by a digital controller.

The Core Components

A typical weighing filler consists of three key parts:

- A Load Cell (The Scale): This is the heart of the machine. The container rests on this electronic scale, which provides continuous, real-time weight data to the controller.

- A Dispensing System (The Valve): This can be a nozzle, auger, or valve that controls the flow of the product from a larger hopper or tank into the container.

- A Controller (The Brain): This digital interface allows an operator to set the target weight. It receives data from the load cell and tells the dispensing system precisely when to start and, more importantly, when to stop.

The Filling Process Explained

The process is a model of precision and efficiency. First, the empty container is placed on the load cell, and the machine automatically "tares" it, setting the scale to zero.

The controller then opens the valve to begin filling. It often uses a "bulk and dribble" method—filling rapidly at first (bulk fill) and then slowing the flow as it approaches the target weight (dribble fill) to avoid overshooting.

The instant the load cell registers that the target weight has been achieved, the controller signals the valve to shut off completely. The result is a container filled to an exact weight, independent of product density or temperature variations.

Why Precision Weighing is Crucial

Relying on volume or manual filling introduces inaccuracies that can be surprisingly costly. A weighing filler directly solves these fundamental business challenges.

Eliminating Density Variations

Products like honey, syrups, or oils change density with temperature. A volumetric filler dispensing 1 liter of cold, dense honey will give away more product by weight than when dispensing 1 liter of warm, less-dense honey. A weighing filler ignores volume and focuses only on the commercial unit of measure: weight.

Ensuring Commercial Compliance

Most regions have strict "weights and measures" regulations for pre-packaged goods. Consistently under-filling can lead to legal penalties and forced recalls. A weighing filler provides the accuracy needed to confidently meet these legal standards.

Reducing Product Giveaway

Overfilling, even by a few grams per container, adds up to significant financial loss. If you overfill by just 2 grams on a 500-gram jar, you give away one free jar for every 250 you produce. Across thousands of units, this "product giveaway" erodes profit margins.

Building Customer Trust

Customers expect to receive the amount of product they paid for. Inconsistent fill levels can damage a brand's reputation. Precision weighing ensures that every customer has the same positive experience, reinforcing the quality and integrity of your brand.

Understanding the Trade-offs

While powerful, a weighing filler is a strategic choice with specific considerations. It is not universally superior to all other filling methods for every application.

Speed vs. Absolute Accuracy

For some high-throughput operations where minor weight variations are acceptable, volumetric fillers can sometimes be faster. The primary trade-off is choosing between maximum speed (volumetric) and maximum accuracy (weighing). Weighing fillers are often chosen when the cost of inaccuracy outweighs the need for marginal gains in speed.

Initial Investment

A precision weighing filling machine represents a higher initial capital investment compared to manual methods or simple volumetric systems. The return on this investment is calculated through reduced product loss and labor costs over time.

Product and Container Suitability

These machines excel with liquids, semi-solids, powders, and granules where weight is the key metric. They are less practical for products sold by count (e.g., screws) or for containers that are not stable enough to sit reliably on a scale during the fill cycle.

Making the Right Choice for Your Operation

Deciding on a weighing filler depends entirely on your operational priorities.

- If your primary focus is brand reputation and legal compliance: A weighing filler is non-negotiable for ensuring every package meets its labeled weight.

- If your primary focus is maximizing profitability: The machine's ability to eliminate product giveaway offers a direct and measurable return on investment, especially at scale.

- If your primary focus is automation and consistency: This system automates a critical and error-prone manual task, delivering identical results hour after hour with minimal oversight.

Ultimately, investing in a weighing filling machine is an investment in certainty and control over your final product.

Summary Table:

| Aspect | Benefit of a Weighing Filler |

|---|---|

| Accuracy | Fills to an exact target weight, independent of product density or temperature. |

| Compliance | Meets strict "weights and measures" regulations to avoid legal penalties. |

| Profitability | Eliminates costly product giveaway from overfilling. |

| Consistency | Automates filling for identical results, building customer trust. |

Ready to eliminate product giveaway and ensure precise, compliant packaging?

HONESTBEE supplies robust and accurate weighing filling machines and a full range of beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations are designed to help your business maximize profitability and build a trusted brand.

Contact us today to find the perfect filling solution for your honey, syrup, or other products!

Visual Guide

Related Products

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- How do automatic Honey-filling Machines improve processing standards? Elevate Accuracy and Hygiene in Large Apiaries

- Why is professional honey filling and processing equipment necessary for Hovenia dulcis honey commercialization?

- What are the primary functions and benefits of industrial-grade automated honey filling equipment? Scaling Your Success

- What are the main functions of a honey sachet packing machine? Boost Efficiency with Automated Precision

- What operational advantages does automated honey filling machinery provide? Scale Your Honey Production Efficiently

- What role does commercial honey filtration and filling machinery play in export-oriented production? | HONESTBEE Guide

- How do industrial honey-filling machines contribute to the commercialization? Master Precision & Quality Control

- How does automated honey filling machinery assist in controlling microbial contamination? Optimize Your Honey Purity