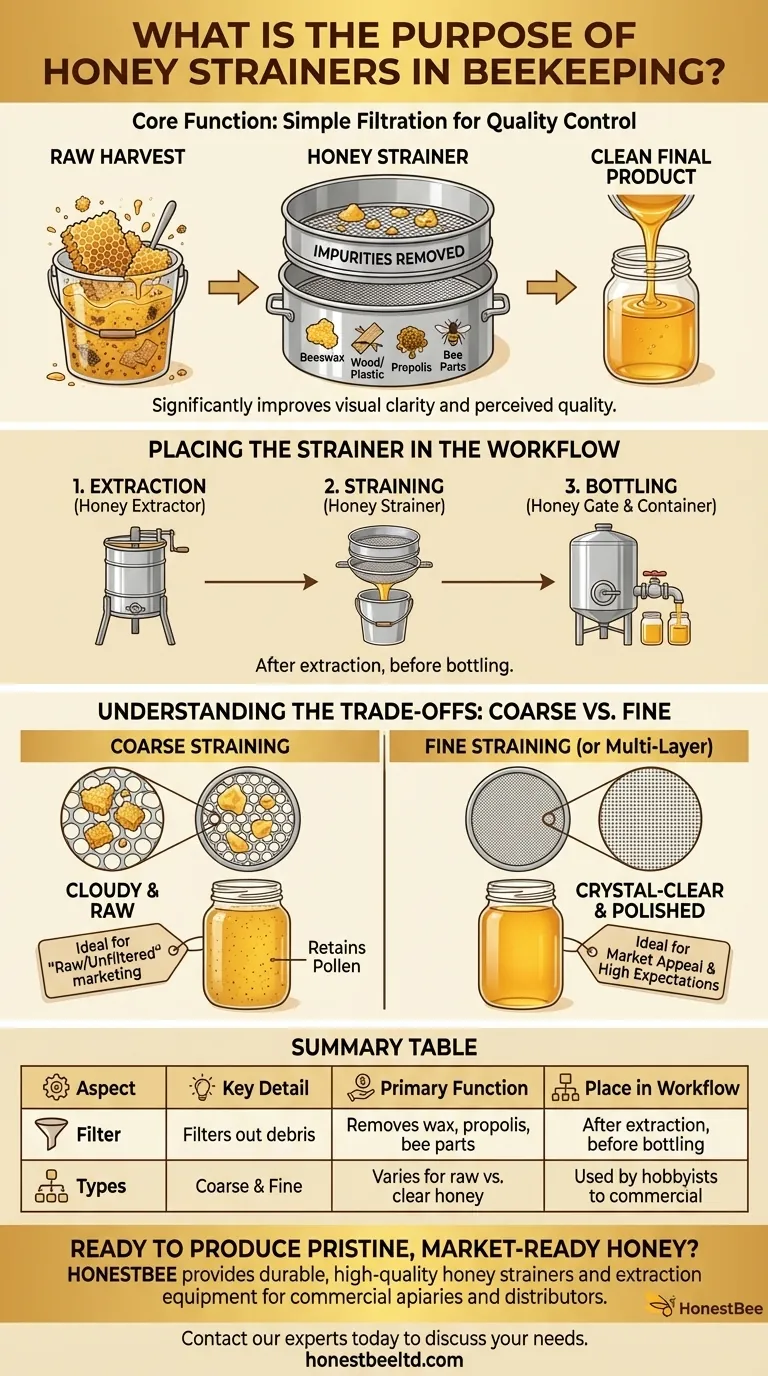

At its core, a honey strainer is a simple filtration tool. Its primary purpose is to remove unwanted debris from raw honey after it has been extracted from the comb. This essential step ensures the final product is clean, clear, and visually appealing for consumption or sale.

The use of a honey strainer is a critical quality control step that directly impacts the purity and marketability of honey. It's the simple bridge between a raw, messy harvest and a clean, high-quality final product.

The Core Function: Separating Honey from Debris

After honey is removed from the honeycomb frames, it contains more than just pure honey. The extraction process, whether by centrifuge or a crush-and-strain method, introduces various particles that need to be removed.

What Impurities Are Removed?

The main goal of straining is to catch physical impurities. This commonly includes bits of beeswax, wood or plastic from the frames, propolis, and occasionally, parts of bees that were caught during the harvest.

How a Strainer Works

A honey strainer is fundamentally a mesh screen or cloth designed to let liquid honey pass through while capturing solid particles. They are typically made of stainless steel or food-grade nylon.

These strainers are often designed to fit over a standard bucket or bottling tank, making them easy to incorporate into a small-scale extraction workflow.

The Impact on Final Quality

Unstrained honey can appear cloudy and may contain unappealing specks of debris. By filtering these out, the strainer significantly improves the visual clarity and perceived quality of the honey, which is crucial for both personal satisfaction and consumer expectations.

Placing the Strainer in the Beekeeping Workflow

While many tools are involved in beekeeping, the strainer has a very specific and important role that happens after the honey has been removed from the comb.

A Tool for Every Beekeeper

Honey strainers are particularly valued for their simplicity and cost-effectiveness. This makes them an ideal and accessible tool for hobbyists and small-scale beekeepers who need an affordable way to process their harvest without investing in expensive machinery.

Differentiating from Other Equipment

It's important not to confuse a strainer with other tools. A honey extractor separates honey from the comb, and a honey gate is a valve used to control the flow of honey out of a container. The strainer's job happens after extraction and before bottling.

Understanding the Trade-offs

While straining is necessary, the degree of filtration is a key decision for the beekeeper. This choice depends on the desired end product.

Coarse vs. Fine Straining

Strainers come in various mesh sizes (measured in microns). A coarse strainer might only remove large pieces of wax and debris, leaving smaller particles like pollen in the honey.

A fine strainer, or a system with multiple layers of progressively finer mesh, will produce a much clearer, more polished final product by removing almost all suspended particles.

The "Raw Honey" Consideration

Some consumers and producers believe that fine filtering can remove beneficial components like pollen. For beekeepers marketing their product as "raw" or "unfiltered," minimal straining with a coarse filter is often a deliberate choice to retain these elements.

Making the Right Choice for Your Goal

The type of straining you perform should align directly with your objectives as a beekeeper.

- If your primary focus is honey for personal use: A simple, single-stage strainer is perfectly adequate to ensure your honey is clean and free of large debris.

- If your primary focus is selling honey at a market: A double-strainer system (one coarse, one fine) is recommended to produce a crystal-clear product that meets high consumer expectations for visual appeal.

- If your primary focus is marketing "raw and unfiltered" honey: Use a very coarse strainer to remove only the largest pieces of wax, and be sure to educate your customers on why their honey may appear less clear.

Ultimately, the honey strainer is an indispensable tool that empowers you to control the final quality and presentation of your harvest.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Filters out debris (wax, propolis, bee parts) from extracted honey. |

| Place in Workflow | Used after extraction and before bottling. |

| Common Types | Coarse strainers (for raw honey) and fine strainers (for clear honey). |

| Ideal For | Hobbyists, small-scale beekeepers, and commercial apiaries. |

Ready to produce pristine, market-ready honey?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-quality honey strainers and extraction equipment you need to ensure a superior final product. Our wholesale-focused operations are designed to support your business's scale and efficiency.

Contact our experts today to discuss your specific needs and discover how our supplies can enhance your honey processing workflow.

Visual Guide

Related Products

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What are the key features of a double sieve honey strainer? Achieve Fast, Clean Honey Processing

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- How does a multi-layer stainless steel honey strainer improve quality? Ensure Pure, Professional-Grade Honey Results

- What is a steel strainer used for? A Kitchen Essential for Precision & Hygiene

- What is the crush and strain method for extracting honey? A Simple Guide to Low-Cost Honey Harvesting