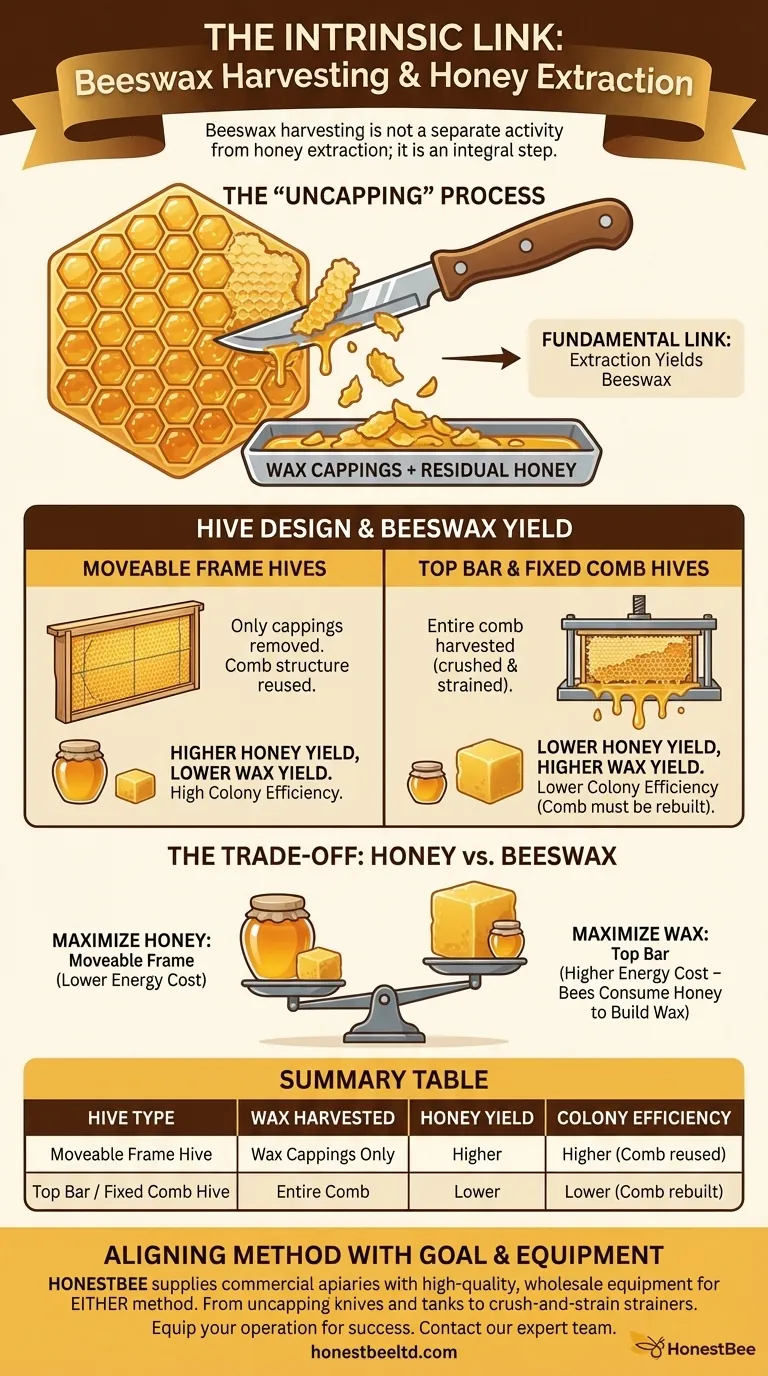

Beeswax harvesting is not a separate activity from honey extraction; it is an integral and unavoidable step in the process. To access the liquid honey stored within a honeycomb, beekeepers must first remove the protective beeswax seals, known as cappings, that the bees create. This means that you cannot extract honey without collecting at least some beeswax.

The core relationship is simple: honey is stored in wax cells that are sealed with wax caps. To extract the honey, beekeepers must first remove these caps. This "uncapping" process makes the collection of beeswax an essential and built-in part of every honey harvest.

The Fundamental Link: How Extraction Yields Beeswax

The connection between honey and wax is rooted in the bee's natural process for storing food. Understanding this cycle makes the harvesting relationship clear.

The Role of Wax Cappings

Bees place nectar into hexagonal wax cells and dehydrate it to create honey. Once the honey reaches the right moisture content, they seal the cell with a fresh layer of beeswax. This capping protects the honey and keeps it preserved.

The "Uncapping" Process

To release the honey, a beekeeper must first slice off these wax cappings. This is typically done with a heated hot knife or a special scraper. This single action is the primary source of harvested beeswax in most modern beekeeping operations.

Collecting the Harvested Wax

As the cappings are scraped from the frames of honeycomb, they fall into a collection tray. These wax cappings, mixed with a good amount of residual honey, are set aside and can be stored in an airtight container for later processing and cleaning.

How Hive Design Influences the Beeswax Yield

While all honey extraction yields beeswax, the amount of wax you harvest is directly determined by the type of beehive you manage.

Moveable Frame Hives

Most modern hives use moveable frames, which often contain a pre-made sheet of beeswax called "foundation." This foundation, sometimes reinforced with wire, gives the bees a guide and provides stability, allowing the honeycomb to be spun in an extractor without breaking.

In this system, only the wax cappings are removed. The main honeycomb structure is left intact, returned to the hive, and reused by the bees. This method yields the least amount of beeswax but is highly efficient for honey production.

Top Bar and Fixed Comb Hives

Older or more natural hive designs, like top bar hives, do not use frames or foundation. The beekeeper harvests the entire comb.

To extract the honey, the entire comb is cut out and then crushed and strained. This process harvests all the beeswax in the comb, not just the cappings, resulting in a much higher beeswax yield per harvest.

Understanding the Trade-offs

The choice of hive and extraction method comes down to a critical trade-off between honey yield and beeswax yield, which is directly tied to the energy expenditure of the bee colony.

Maximizing Honey vs. Maximizing Wax

A moveable frame hive is optimized for honey production. Because the bees do not have to rebuild their entire comb after each harvest, they can dedicate their energy exclusively to foraging for nectar and making more honey.

The High Cost of Building Comb

Producing beeswax is an incredibly energy-intensive process for honeybees. When the entire comb is harvested (as in a top bar hive), the colony must consume a significant amount of honey just to fuel the creation of new wax before they can even begin storing the next honey crop.

Efficiency for the Colony

Preserving the drawn comb in a frame hive is far more efficient for the bees, leading to greater honey surpluses. The crush-and-strain method provides the beekeeper with more wax but at a higher energy cost to the colony.

Aligning Your Method With Your Goal

Your beekeeping goals should dictate your harvesting technique, as the two are fundamentally linked.

- If your primary focus is maximizing honey production and colony efficiency: Use a moveable frame hive where only the wax cappings are harvested, preserving the core comb structure.

- If your primary focus is a significant beeswax harvest alongside honey: A top bar or fixed comb hive is the better choice, as the entire comb is harvested via the crush-and-strain method.

Understanding this intrinsic link empowers you to choose a beekeeping method that perfectly aligns with your desired balance of honey and beeswax.

Summary Table:

| Hive Type | Wax Harvested | Honey Yield | Colony Efficiency |

|---|---|---|---|

| Moveable Frame Hive | Wax Cappings Only | Higher | Higher (Comb is reused) |

| Top Bar / Fixed Comb Hive | Entire Comb | Lower | Lower (Comb is rebuilt) |

Optimize Your Honey and Wax Harvest with the Right Equipment

Understanding the trade-off between honey and beeswax yield is key to a successful operation. Whether you manage moveable frame hives for maximum honey production or top bar hives for higher wax yields, having reliable, efficient equipment is crucial.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-priced supplies needed to support either method. From durable uncapping knives and tanks for frame hives to robust strainers for crush-and-strain processing, we provide the tools for a productive harvest.

Let us help you equip your operation for success. Contact our expert team today to discuss your specific needs and explore our full range of beekeeping supplies.

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What is the necessity of 1:2 ratio bevel gears in manual honey extractors? Optimize Extraction Speed and Efficiency

- What are the differences between manual and automatic honey extractors? Choose the Right Tool for Your Apiary

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb

- What tips can maximize honey extraction efficiency? Unlock Higher Yields and Purer Honey

- How many frames can different types of honey extractors hold? Maximize Your Harvest Efficiency