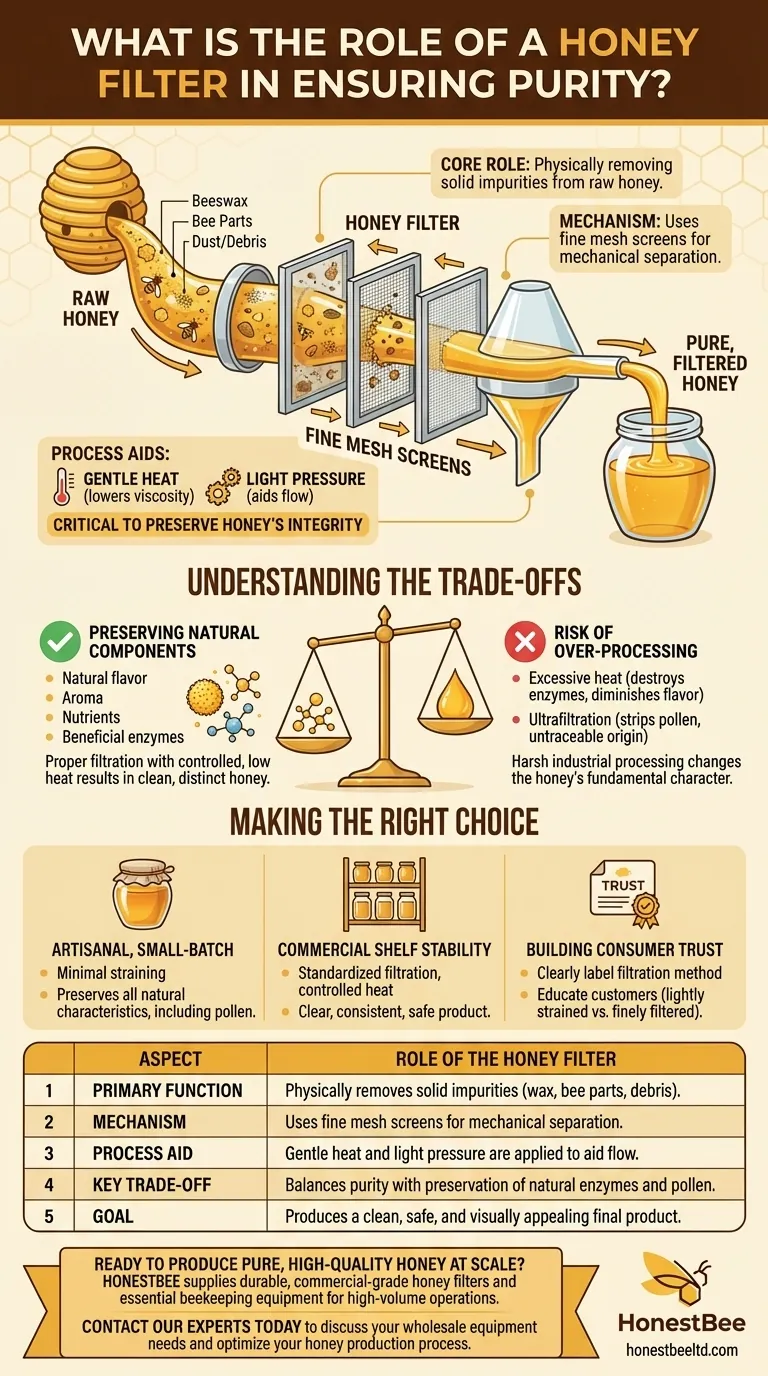

At its core, a honey filter’s role is to ensure purity by physically removing solid impurities from raw honey. This process uses a series of screens or filters to trap unwanted matter—such as wax particles, bee parts, and environmental debris—before the honey is bottled. To aid this separation without damaging the product, gentle heat and light pressure are often applied to make the viscous honey flow more easily.

The central purpose of honey filtration is to produce a clean, safe, and visually appealing product that meets consumer expectations. However, the method and intensity of filtration directly determine whether the honey's natural character, including beneficial enzymes and pollen, is preserved or stripped away.

How a Honey Filter Achieves Purity

A honey filter works on the principle of mechanical separation. It does not chemically alter the honey; it simply acts as a physical gatekeeper, allowing liquid honey to pass while holding back solid contaminants.

Targeting Physical Impurities

Raw honey, straight from the hive, naturally contains various solids that are undesirable in the final product. A filter is designed specifically to remove these.

Common impurities include bits of beeswax, fragments of bee parts, splinters from the wooden hive frames, and environmental debris like dust and dirt.

The Mechanism of Separation

The filtration system uses one or more fine mesh screens. As honey is passed through, these screens physically trap particles larger than the mesh size.

Commercial operations may use a series of progressively finer filters to ensure a thoroughly clean product. This is a crucial step for creating the crystal-clear honey many consumers expect to see on store shelves.

The Role of Temperature and Pressure

Honey is highly viscous, meaning it is thick and resists flowing. Trying to filter cold, thick honey is extremely slow and inefficient.

To overcome this, producers gently warm the honey. This lowers its viscosity, allowing it to flow through the filters much more quickly. A small amount of pressure may also be applied to assist the flow, ensuring an efficient process without damaging the honey's delicate structure.

Understanding the Trade-offs

While filtration is necessary, the specific technique used involves critical trade-offs between purity and the preservation of natural compounds. The goal is to clean the honey, not to fundamentally change it.

Preserving Natural Components

Proper, gentle filtration with controlled, low heat is designed to preserve the honey's natural flavor, aroma, and nutrients. The objective is to remove only the unwanted solid matter.

When done correctly, the process results in a clean product that still contains the beneficial enzymes and volatile compounds that give different honey varieties their unique characteristics.

The Risk of Over-Processing

The primary risk in this process comes from excessive heat. If honey is heated too much or for too long, its delicate enzymes can be destroyed, and its complex flavor profile can be diminished.

This is the key difference between careful filtering and harsh industrial processing. Maintaining low temperatures is critical to preserving the integrity of the honey.

The Pollen Controversy

Standard filtration removes large debris but leaves behind microscopic pollen grains. These grains are harmless and are used by experts to trace a honey's geographical and floral origin.

However, some large-scale producers use a process called ultrafiltration, which uses extremely fine filters and high pressure. This can strip pollen from the honey, making its origin untraceable. While technically "pure" from debris, many purists argue that such honey has lost a key part of its natural identity.

Making the Right Choice for Your Goal

Your filtration strategy should align directly with your end goal, whether you are a hobbyist beekeeper or a commercial producer.

- If your primary focus is artisanal, small-batch honey: Minimal straining is best to remove only the largest debris while preserving all natural characteristics, including pollen.

- If your primary focus is commercial shelf stability: A standardized filtration process with carefully controlled heat is necessary to deliver a clear, consistent, and safe product that meets broad consumer expectations.

- If your primary focus is building consumer trust: Clearly label your filtration method to educate customers on whether the honey is lightly strained or finely filtered.

Ultimately, understanding filtration empowers you to produce honey that aligns with your quality standards and your promise to the end consumer.

Summary Table:

| Aspect | Role of the Honey Filter |

|---|---|

| Primary Function | Physically removes solid impurities (wax, bee parts, debris). |

| Mechanism | Uses fine mesh screens for mechanical separation. |

| Process Aid | Gentle heat and light pressure are applied to aid flow. |

| Key Trade-off | Balances purity with preservation of natural enzymes and pollen. |

| Goal | Produces a clean, safe, and visually appealing final product. |

Ready to produce pure, high-quality honey at scale?

For commercial apiaries and beekeeping equipment distributors, the right filtration system is critical for efficiency and product integrity. HONESTBEE supplies durable, commercial-grade honey filters and essential beekeeping equipment designed for high-volume, wholesale operations.

We help you achieve the perfect balance of purity and preservation, ensuring your honey meets the highest standards. Contact our experts today to discuss your wholesale equipment needs and optimize your honey production process.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- Why is filtering honey an important step in honey processing? Ensure Purity, Clarity & Marketability

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability

- How does automated honey filtration and filling machinery improve quality? Guard Your Apiary Against Pest Contamination