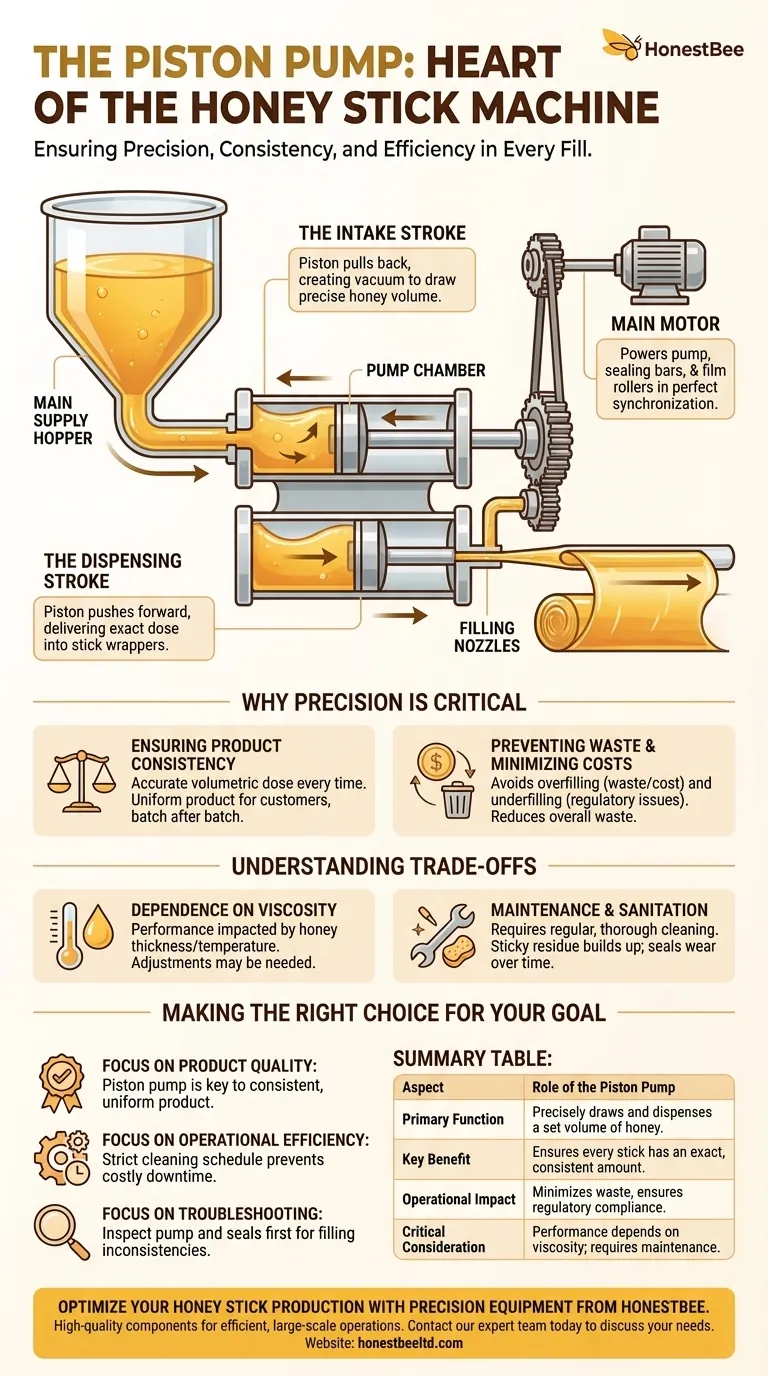

In short, the piston pump is the heart of the filling process. It is a cylindrical component that mechanically moves back and forth, precisely drawing a set volume of honey from the main supply hopper and then dispensing it into the individual stick wrappers through the filling nozzles.

The piston pump's primary role is not just to move honey, but to ensure that every single honey stick is filled with an exact, consistent, and repeatable amount of product. This precision is critical for product quality and operational efficiency.

How the Piston Pump Mechanism Works

To understand the machine, you must first understand the simple but effective mechanics of its core filling component. The pump operates in a two-stroke cycle, powered by the machine's main motor.

The Intake Stroke

The cycle begins when the piston pulls back within its cylinder. This backward motion creates a vacuum, which draws honey from the main hopper into the pump's chamber.

The Dispensing Stroke

Once the chamber is full, the piston moves forward. This forward motion pushes the captured volume of honey out of the chamber and through the filling nozzles, delivering a precise dose into the prepared honey stick film.

The Link to the Motor

This entire mechanical back-and-forth action is not isolated. It is driven by the machine's main motor, which converts electrical energy into the mechanical force needed to run the pump, sealing bars, and film rollers in perfect synchronization.

Why This Precision is Critical

The choice of a piston pump is deliberate, as it directly addresses the most important requirements of packaging a liquid product like honey.

Ensuring Product Consistency

The fundamental advantage of a piston pump is its ability to dispense a highly accurate volumetric dose every single time. This guarantees that a customer buying a honey stick today gets the exact same amount of product as one buying it a year from now.

Preventing Waste and Minimizing Costs

Inaccurate filling leads to two problems: overfilling, which wastes product and increases costs, and underfilling, which can lead to regulatory issues and unhappy customers. The pump's precision minimizes both, reducing waste and ensuring compliance.

Understanding the Trade-offs

While highly effective, this mechanical system has operational considerations that must be managed for optimal performance.

Dependence on Viscosity

Piston pumps are excellent for liquids like honey. However, their performance can be impacted by significant changes in product viscosity. Thicker, colder honey may require adjustments to pump speed or heating the hopper to flow correctly.

Maintenance and Sanitation

As a mechanical component in direct contact with the food product, the piston pump requires regular and thorough cleaning. Sticky residue can build up, affecting accuracy and hygiene if not properly maintained. Parts like seals can also wear over time and require replacement.

Making the Right Choice for Your Goal

Understanding the piston pump's role allows you to manage your production process more effectively.

- If your primary focus is product quality: Recognize that the piston pump is your key to delivering a consistent and uniform product to your customers.

- If your primary focus is operational efficiency: Implement a strict cleaning and maintenance schedule for the pump to prevent costly downtime and product waste.

- If your primary focus is troubleshooting: When filling inconsistencies occur, the piston pump and its seals should be one of the first components you inspect.

Ultimately, mastering the function of the piston pump is fundamental to mastering your honey stick production.

Summary Table:

| Aspect | Role of the Piston Pump |

|---|---|

| Primary Function | Precisely draws and dispenses a set volume of honey into stick wrappers. |

| Key Benefit | Ensures every honey stick has an exact, consistent amount of product. |

| Operational Impact | Minimizes product waste and ensures regulatory compliance. |

| Critical Consideration | Performance depends on honey viscosity and requires regular maintenance. |

Optimize Your Honey Stick Production with Precision Equipment

Mastering your filling process starts with reliable machinery. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable components needed for efficient, large-scale operations. Whether you're scaling up production or need to replace critical parts like piston pumps, our wholesale-focused operations are designed to support your business.

Contact our expert team today to discuss your equipment needs and ensure your honey sticks are filled with perfect consistency, batch after batch.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- How does high-precision honey filling machinery help improve product competitiveness in modern apiary upgrades?

- What is the value of automated honey-filling equipment for commercial pollination operations? Boost Output and Efficiency

- How does an automatic honey-filling machine ensure quality? From Raw Forest Honey to Commercial Success

- How do automated honey-filling machines assist in scaling beekeeping operations for international export? Scale Global

- What is the significance of automated honey filling machines? Boost Purity and Efficiency in Commercial Processing

- What role does industrial honey processing and filling machinery play in forest honey? Boost Your Market Value

- How does industrial-scale honey filling equipment enhance the competitiveness of honey products? Boost Global Export Success

- Why are industrial-grade honey filling machines and specialized packaging materials necessary for honey commercialization?