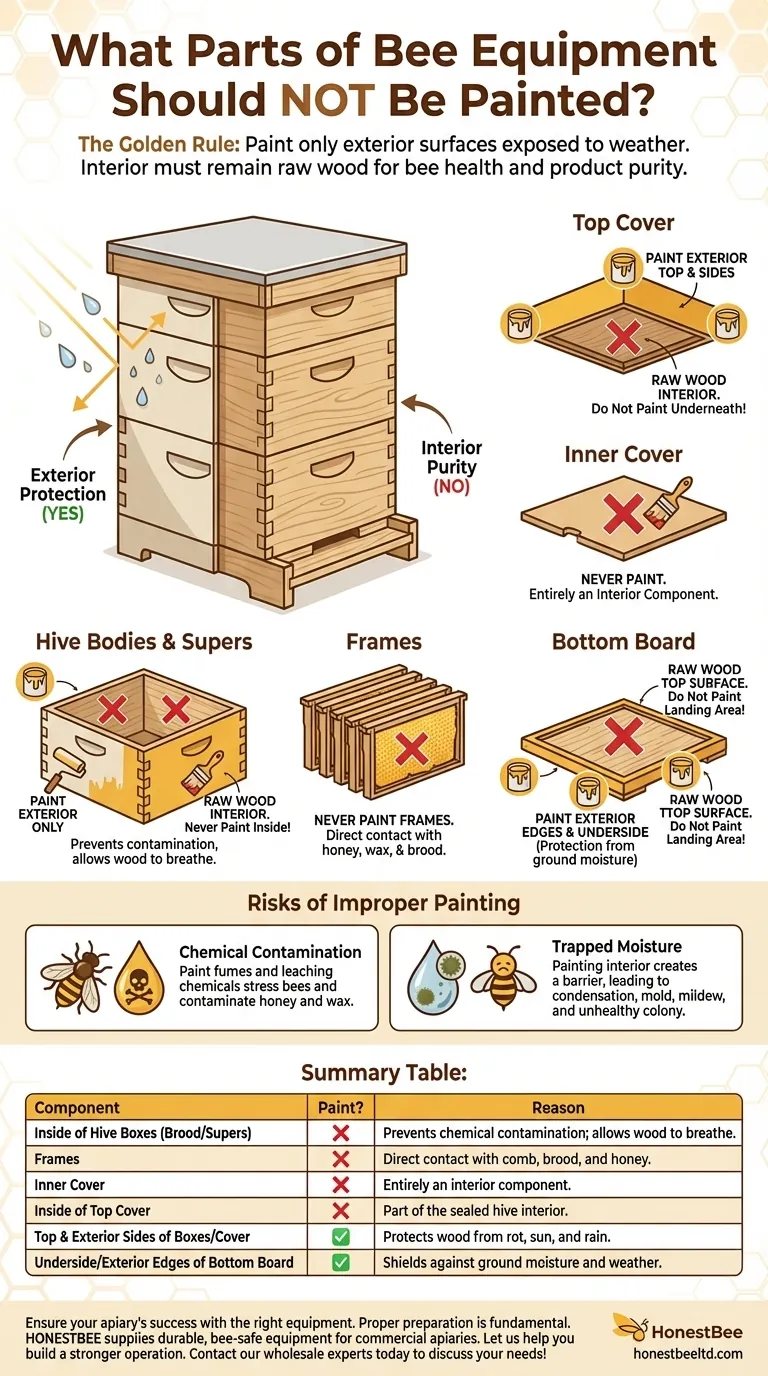

When preparing a beehive, what you don't paint is just as critical as what you do. To protect your bees and their products, you must leave several key interior components completely unfinished. The parts that should never be painted are the inside surfaces of all hive boxes (brood boxes and honey supers), the frames, the inner cover, and the inside of the telescoping top cover.

The fundamental rule is to paint only the exterior surfaces of the hive that are directly exposed to weather. The interior must remain raw wood to ensure bee health, prevent contamination, and allow the wood to breathe.

The Guiding Principle: Exterior Protection vs. Interior Purity

The decision of what to paint on a beehive is not arbitrary. It is guided by two competing needs: protecting the wooden equipment from the elements and maintaining a safe, natural environment for the honey bee colony inside.

Why the Exterior Needs Paint

Any part of your hive that gets wet when it rains or is baked by the sun needs a protective coating. High-quality exterior paint acts as a shield for the wood.

This simple step prevents rot, warping, and decay. A well-painted hive can last for a decade or more, whereas an unpainted one may begin to deteriorate after only a few seasons.

Why the Interior Must Remain Bare

The inside of the hive is the bees' home. They manage this environment themselves, often coating surfaces with propolis, a natural resin with antimicrobial properties.

Introducing paint to this sealed environment can be harmful. It can off-gas chemicals (VOCs) that are unhealthy for the bees and can contaminate the honey and wax they produce.

A Part-by-Part Breakdown

To eliminate any confusion, let's examine each major component of a standard Langstroth hive.

Hive Bodies and Supers

These are the boxes that make up the main structure of the hive.

You should always paint the outside surfaces of these boxes. However, the inside walls must be left as bare wood.

Top Cover

The top cover acts as the roof, providing the primary defense against rain.

Paint the top and all four exterior sides thoroughly. The inside surface should not be painted, as it is not exposed to the elements and is considered part of the hive's interior space.

Inner Cover

The inner cover sits directly on top of the uppermost box, underneath the top cover. It provides bee space and ventilation.

Do not paint any part of the inner cover. It is entirely an interior component.

Frames

Frames are where the bees build their comb, raise their young, and store honey and pollen.

Frames must never be painted. They are in direct contact with every resource the colony produces and uses. Painting them would lead to direct and certain contamination.

Bottom Board

The bottom board is the floor of the hive. The top surface, where the bees walk, should be left unpainted.

The exterior edges and the underside, which are exposed to ground moisture and weather, should be painted for maximum durability.

Understanding the Risks of Improper Painting

Painting interior hive components is not just unnecessary; it creates tangible problems that can harm the colony.

Chemical Contamination

Bees are highly sensitive to their environment. Paint fumes and chemicals leaching from painted interior surfaces can stress or kill bees and will inevitably find their way into the honey and wax.

Trapped Moisture

One of the most overlooked functions of a wooden hive is its ability to breathe. Raw wood can absorb and release excess moisture, helping to regulate the hive's internal humidity.

Painting the inside creates an impermeable vapor barrier. This can trap moisture and condensation, leading to mold, mildew, and a stressed, unhealthy colony.

Making the Right Choice for Your Hive

To ensure both hive longevity and bee safety, follow these simple guidelines.

- If your primary focus is equipment lifespan: Use a high-quality, low-VOC, exterior-grade latex paint on all outside surfaces, applying at least two coats for maximum protection.

- If your primary focus is bee health and safety: Leave all interior surfaces—including the inside of boxes, all frames, and the inner cover—completely unpainted.

- If you are preparing a new hive: Paint the designated exterior parts well before introducing bees to allow the paint to fully cure and off-gas any volatile compounds.

Properly preparing your hive is the first step in creating a safe, productive, and long-lasting home for your colony.

Summary Table:

| Component | Paint? | Reason |

|---|---|---|

| Inside of Hive Boxes (Brood/Supers) | No | Prevents chemical contamination of honey/wax; allows wood to breathe and manage humidity. |

| Frames | No | Direct contact with comb, brood, and honey; painting guarantees contamination. |

| Inner Cover | No | Entirely an interior component; no exposure to weather. |

| Inside of Top Cover | No | Part of the sealed hive interior; not exposed to rain/sun. |

| Top & Exterior Sides of Boxes/Cover | Yes | Protects wood from rot, warping, and sun/rain damage. |

| Underside/Exterior Edges of Bottom Board | Yes | Shields against ground moisture and weather for durability. |

Ensure your apiary's success with the right equipment. Proper hive preparation is fundamental to colony health and honey production. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, high-quality beekeeping supplies designed for longevity and bee safety.

Let us help you build a stronger, more productive operation.

Contact our wholesale experts today to discuss your equipment needs and discover how our products can support your beekeeping success.

Visual Guide

Related Products

- Wooden Bee Hive Frames for Beekeeping and Wholesale

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Heavy-Duty Nylon Beehive Hive Strap with Stainless Steel Cinch Buckle

- Langstroth Honey Bee Box Hive Boxes for Different Depths

- Versatile Ratchet Hive Strap with S-Hooks for Secure Fastening

People Also Ask

- What are the main disadvantages of using 10-frame hives? Understanding Weight & Efficiency Challenges

- What is the role of oxalic acid in plants? A Key to Plant Defense and Internal Regulation

- What are the key considerations when choosing between 8-frame and 10-frame beehives? Selecting Your Ideal Hive Setup

- How do standardized hives with movable frame designs contribute to apiary efficiency? Scale Your Commercial Operations

- How do standardized beehive frames serve as a tool for evaluating colony strength? Measure Bee Health with Precision