For packaging honey in bottles and jars, the most suitable equipment is a dedicated bottle filling machine. These machines are specifically designed to handle the unique viscosity of honey and ensure a clean, accurate fill, whether you are working with glass jars, plastic squeeze bottles, or other rigid containers. They typically use precise shut-off valves and can be integrated into a larger line that includes conveying, capping, and labeling.

The core decision is not simply choosing a bottle filler, but selecting the right type of filler. Your choice between a simple gravity-fed system and a more advanced automatic machine will be driven entirely by your production volume and long-term business goals.

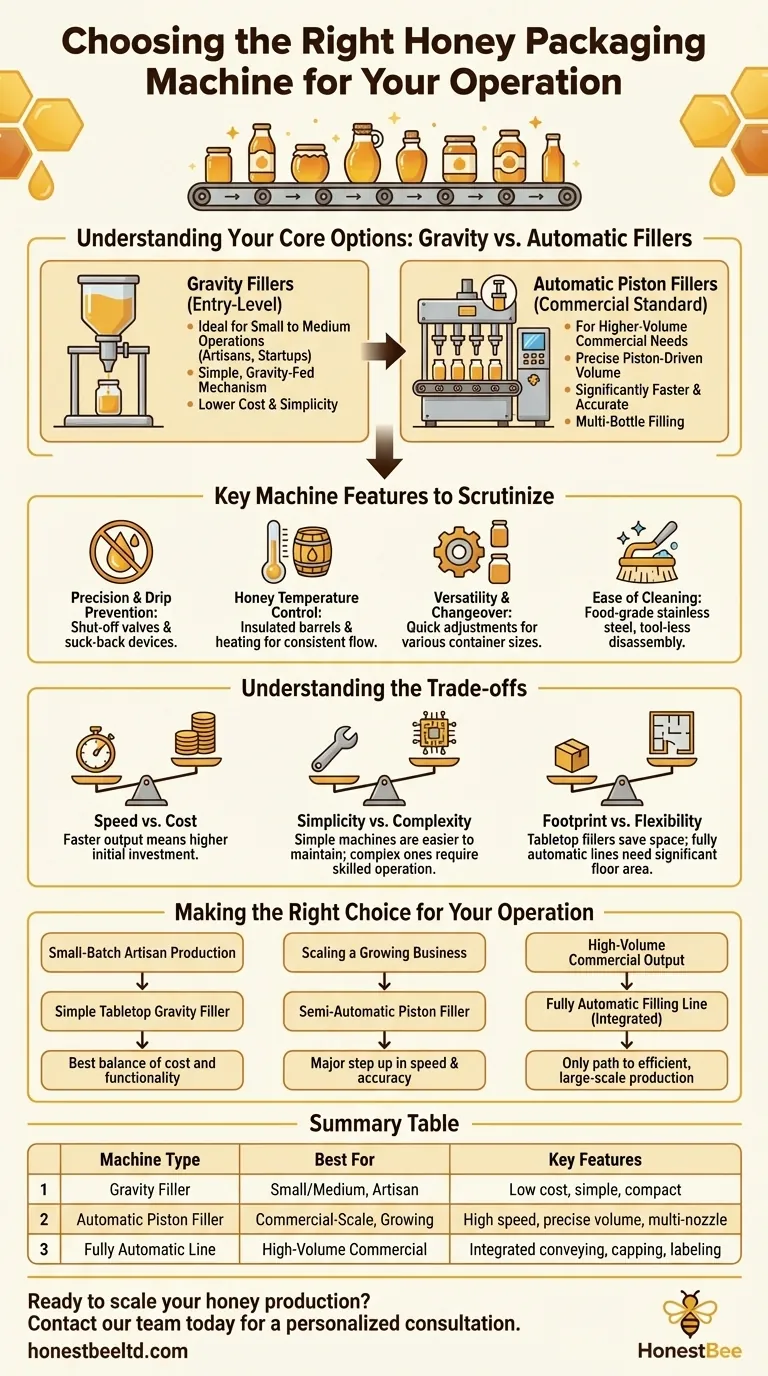

Understanding Your Core Options: Gravity vs. Automatic Fillers

The world of honey bottling machines is primarily divided into two categories based on their filling mechanism and level of automation. Understanding this distinction is the first step to making a sound investment.

Gravity Fillers: The Entry-Level Solution

Gravity fillers are the simplest type of bottling machine. They consist of a bulk tank positioned above the filling nozzles, using gravity to dispense the honey into containers below.

These machines are ideal for small to medium-sized operations, such as artisan beekeepers or those just starting to commercialize their product. Their primary advantages are lower cost and simplicity of operation.

Automatic Piston Fillers: The Commercial Standard

For higher-volume commercial needs, automatic piston fillers are the industry standard. These machines use a piston to pull a precise, repeatable volume of honey from a hopper and dispense it into the container.

They are significantly faster and more accurate than gravity fillers, often capable of filling multiple bottles simultaneously. This makes them essential for any beekeeper looking to achieve significant production scale and consistency.

Key Machine Features to Scrutinize

Beyond the basic type, several specific features determine a machine's true value and suitability for handling honey.

Precision and Drip Prevention

Honey is sticky and prone to mess. Look for machines with precise shut-off valves at the filling nozzle. Advanced models also feature a suck-back device, which pulls the last drop of honey back into the nozzle after a fill, ensuring a clean container and no product waste.

Honey Temperature Control

The viscosity of honey changes dramatically with temperature. A quality machine will feature a double-layer insulated barrel or hopper, sometimes with integrated heating elements. This maintains the honey at an optimal, consistent temperature, ensuring a smooth, even flow rate and accurate fills.

Versatility and Changeover

Your product line may include various jar sizes and shapes. A good machine should be versatile and adaptable, allowing for quick and easy adjustments to accommodate different container heights and volumes without extensive downtime.

Ease of Cleaning and Maintenance

As a food product, hygiene is non-negotiable. Ensure the machine is constructed from food-grade stainless steel and designed for easy disassembly. Quick, tool-less changeover of parts for cleaning is a critical feature that saves significant time and labor.

Understanding the Trade-offs

Choosing the right machine involves balancing cost, speed, and complexity. Being aware of the inherent trade-offs will prevent costly mistakes.

Speed vs. Cost

The most significant trade-off is between output speed and initial investment. A manual gravity filler is highly affordable but slow. A fully automatic filling line offers incredible speed but represents a substantial capital expenditure.

Simplicity vs. Complexity

A gravity filler has few moving parts and is easy to maintain. An automatic piston filler is a more complex piece of equipment that requires more skilled operation and a more involved maintenance schedule.

Footprint vs. Flexibility

Simple tabletop fillers are compact and can fit in small workshops. Fully automatic lines require significant dedicated floor space for the filler, conveyor, capper, and labeler, impacting your facility layout.

Making the Right Choice for Your Operation

Select your equipment by aligning its capabilities directly with the scale and ambition of your honey business.

- If your primary focus is small-batch artisan production: A simple, tabletop gravity filler offers the best balance of cost and functionality.

- If your primary focus is scaling a growing business: A semi-automatic piston filler provides a major step up in speed and accuracy without the cost of a fully automated line.

- If your primary focus is high-volume commercial output: A fully automatic filling line with integrated conveying and capping is the only viable path to efficient, large-scale production.

By matching the machine's technology to your specific production needs, you ensure your investment is both effective today and scalable for tomorrow.

Summary Table:

| Machine Type | Best For | Key Features |

|---|---|---|

| Gravity Filler | Small to medium operations, artisan beekeepers | Low cost, simple operation, compact |

| Automatic Piston Filler | Commercial-scale production, growing businesses | High speed, precise volume control, multi-nozzle filling |

| Fully Automatic Line | High-volume commercial output | Integrated conveying, capping, and labeling |

Ready to scale your honey production with the right equipment?

As a leading supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides high-performance, durable bottling solutions designed for the unique demands of honey. Our experts can help you select the perfect machine—from semi-automatic fillers to complete automated lines—to boost your efficiency, ensure precise fills, and support your business growth.

Contact our team today for a personalized consultation and competitive wholesale pricing.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- What is the primary difference between automated and manual honey filling processes? Scale Efficiency and Precision

- How do industrial honey filling machines address the production challenges associated with high-yield honeybee colonies?

- How does automatic filling equipment ensure product quality? Precision for Propolis and Plant Extracts

- What are the key advantages of volumetric filling machines? Boost Packaging Speed & Flexibility

- What type of product is a bottle filling machine? The Key to Automated, High-Speed Packaging

- What is the process of a liquid filling machine? A Guide to Choosing the Right Filling Method

- What auxiliary machines are used with honey fillers? Build a Complete Automated Production Line

- How does a comprehensive knowledge strategy enhance hive-making and honey-filling efficiency? Optimize Your Bee Hardware