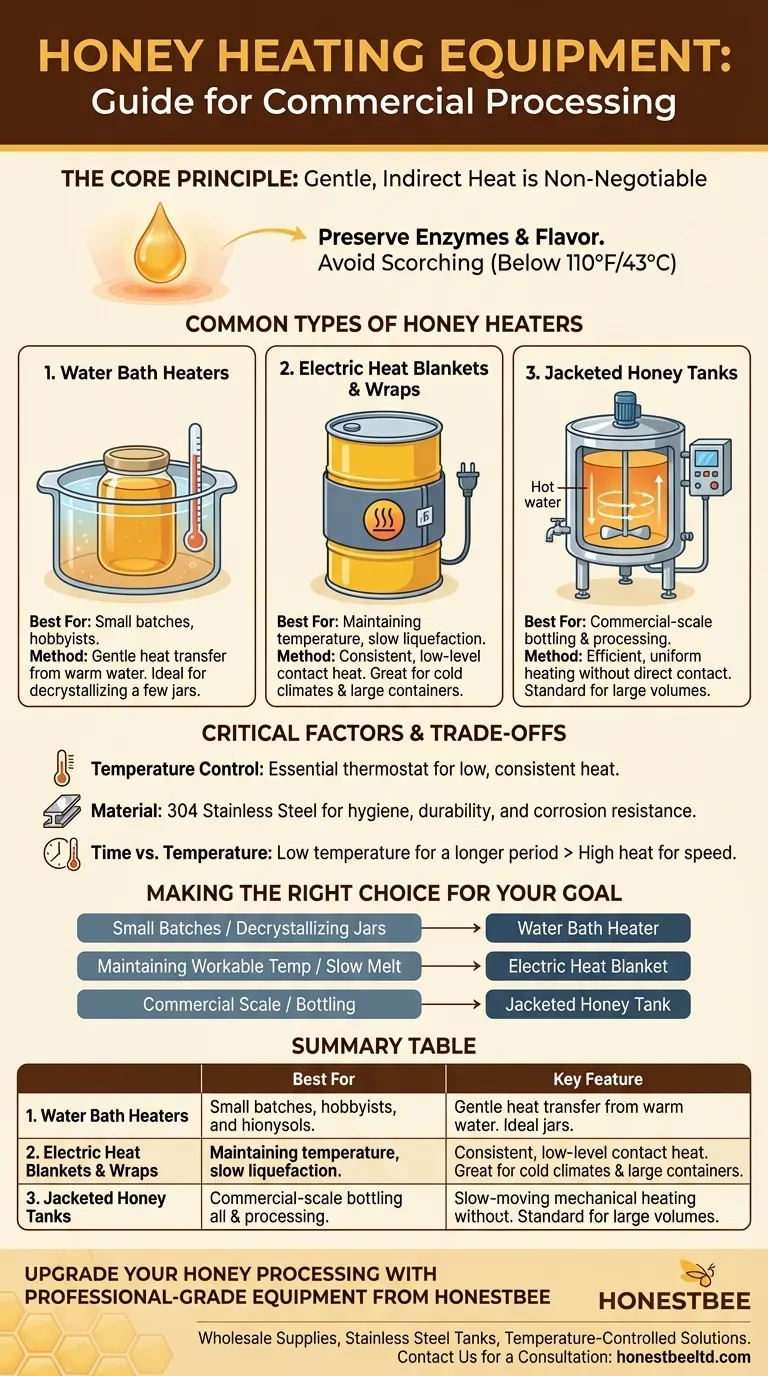

The most common types of honey heating equipment are water bath heaters, electric heat blankets or wraps, and jacketed honey tanks. Each uses a method of gentle, indirect heat to warm honey without scorching it, which is essential for liquefying crystallized honey or preparing it for bottling while preserving its natural quality.

The central challenge in heating honey is not just to warm it, but to do so without destroying its delicate enzymes, flavors, and aromas. Therefore, the best equipment is always that which provides gentle, indirect, and precisely controlled low-temperature heat.

The Core Principle: Why Gentle Heat is Non-Negotiable

Honey is a sensitive product. Aggressive or direct heat can fundamentally damage it, leading to a darker color, altered taste, and the destruction of beneficial enzymes like diastase and invertase.

The goal of any heating equipment is simply to make the honey more workable by reducing its viscosity or to gently melt the glucose crystals that cause it to solidify.

The Impact of Overheating

Applying too much heat—generally considered to be over 110°F (43°C) for extended periods—can degrade the honey. This is why direct heating elements are almost never used.

Common Types of Honey Heaters

Equipment choices typically scale with the volume of honey being processed, from a single jar to a commercial batch.

Water Bath Heaters

This is the simplest method, often used by hobbyists. A container of honey is placed inside a larger vessel of warm water, allowing for very gentle heat transfer.

This technique is ideal for decrystallizing a few jars or a small bucket of honey where precise temperature control is less critical.

Electric Heat Blankets and Wraps

These are insulated blankets or flexible bands with built-in, low-wattage heating elements. They are designed to wrap directly around a bucket, drum, or tank.

Their primary advantage is providing consistent, low-level heat over a long period. This is especially useful for maintaining honey at a workable temperature in colder climates or slowly liquefying a large, crystallized container.

Jacketed Honey Tanks

For commercial-scale operations, jacketed tanks are the standard. These are typically large, stainless steel vats with a second outer wall, creating a "jacket."

Hot water circulates within this jacket, warming the honey evenly and efficiently without any direct contact between the heat source and the honey. Many are equipped with a slow-moving stirrer to ensure uniform temperature throughout the batch.

Understanding the Trade-offs and Critical Factors

Selecting the right equipment involves more than just picking a heater; it requires understanding the factors that protect your honey's quality.

Temperature Control is Paramount

Regardless of the device, a reliable thermostat is essential. The ability to set and hold a specific, low temperature prevents accidental overheating and ensures consistent results.

The Importance of Material: 304 Stainless Steel

Professional-grade honey processing equipment is almost always made from 304 stainless steel.

This material is chosen for its excellent durability, high resistance to corrosion, and hygienic, non-porous surface. It ensures no undesirable flavors are imparted to the honey and makes cleaning simple and effective.

Time vs. Temperature

A critical trade-off exists between time and temperature. It is always better to warm honey at a lower temperature for a longer period than to try and speed up the process with high heat. Patience protects the product.

Making the Right Choice for Your Goal

Your ideal equipment depends entirely on your operational scale and what you need to achieve.

- If your primary focus is decrystallizing small batches or single jars: A simple water bath heater is the most effective and economical solution.

- If your primary focus is keeping honey workable in a cool environment: An electric heat blanket provides the steady, low-level warmth needed to prevent thickening and crystallization.

- If your primary focus is large-scale processing for bottling: A jacketed honey tank offers the necessary control, consistency, and efficiency for commercial volumes.

Ultimately, choosing the right tool is about protecting the integrity and value of your honey.

Summary Table:

| Equipment Type | Best For | Key Feature |

|---|---|---|

| Water Bath Heater | Small batches, hobbyists | Gentle, indirect heat from warm water |

| Electric Heat Blanket/Wrap | Maintaining temperature, slow liquefaction | Consistent, low-level heat over long periods |

| Jacketed Honey Tank | Commercial-scale bottling & processing | Efficient, uniform heating with a stirrer |

Upgrade Your Honey Processing with Professional-Grade Equipment from HONESTBEE

As a commercial apiary or beekeeping equipment distributor, the quality of your honey is your most valuable asset. Protecting its delicate flavor, aroma, and beneficial enzymes during heating is non-negotiable. HONESTBEE supplies the durable, precise, and efficient honey heating solutions you need to scale your operations without compromising quality.

We provide wholesale-focused supplies, including stainless steel jacketed tanks and temperature-controlled equipment, designed for durability and consistent performance. Let us help you choose the right equipment to maximize your honey's value and streamline your workflow.

Contact HONESTBEE today for a consultation on the best heating solutions for your commercial needs!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

People Also Ask

- Is it safe to heat raw honey? Preserve the health benefits of your raw honey

- How can granulated honey be re-liquified? The Safe & Simple Guide to Restoring Liquid Honey

- How do modern standardized beehives with integrated heating systems support stingless bees? Optimize Colony Survival

- What are the technical advantages of using water bath heating equipment in honey processing? Preserve Quality & Purity

- What is the primary role of a honey heating tank? Enhance Your Honey Processing Flow and Quality

- Can you heat honey to melt it? Yes, with the right gentle methods to preserve quality.

- How do industrial-grade constant temperature paraffin dipping tanks improve epidemic prevention? Expert Bio-Security

- Why is the use of precision temperature-controlled heating equipment necessary? Protect Your Bees from HMF Toxicity