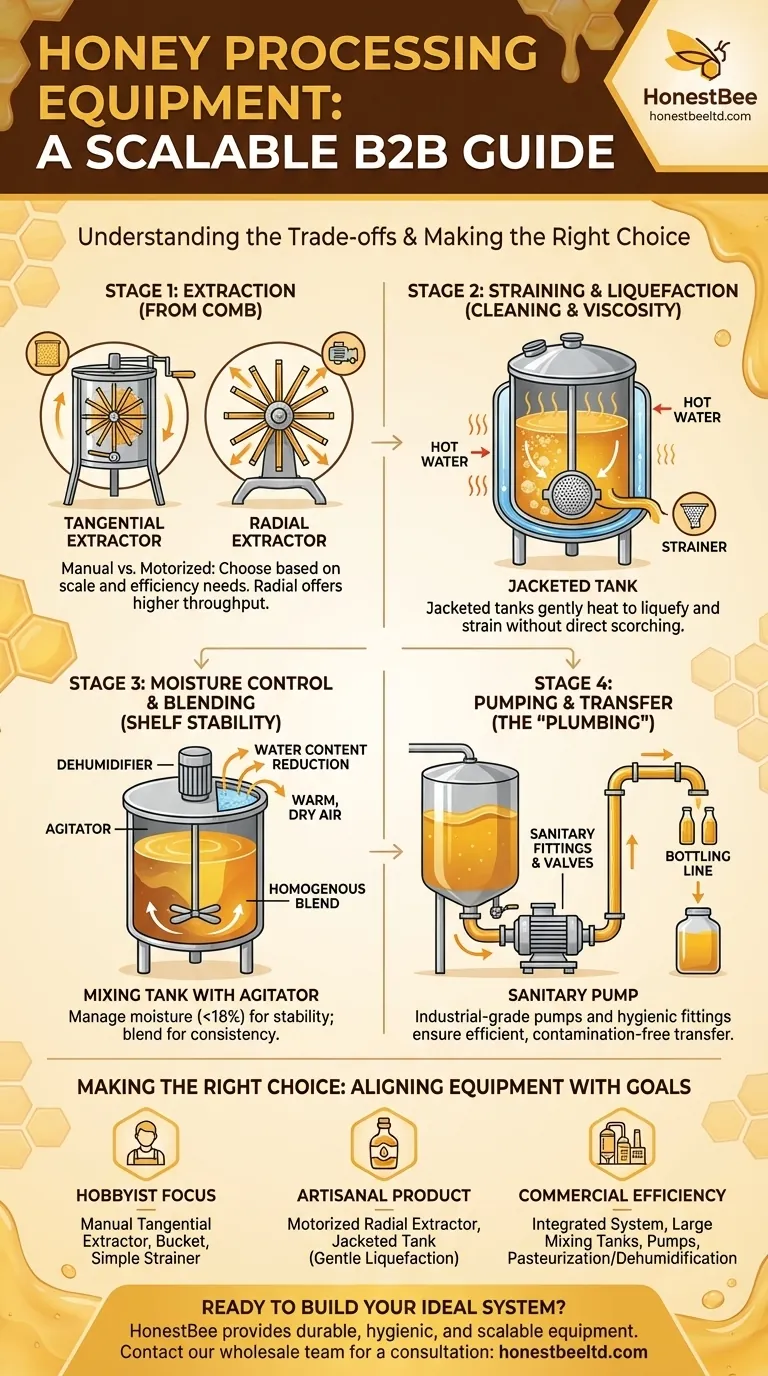

Honey processing equipment spans a wide range of tools designed for every stage of production. At its core, the available equipment includes extractors to remove honey from the comb, various tanks for heating and mixing, and pumps with sanitary fittings to transfer the product. This system can be as simple as a hand-cranked extractor for a hobbyist or as complex as a fully automated plant for a commercial producer.

The essential takeaway is not the list of available machines, but the understanding that honey processing equipment forms a scalable system. Your choice of equipment should be driven directly by your operational scale and the specific characteristics you want in your final honey product.

From Comb to Container: A Breakdown of the Process

To understand the equipment, it's best to view it through the lens of the honey production workflow. Each piece of equipment serves a distinct purpose at a specific stage.

Stage 1: Extraction

This is the foundational step of separating honey from the beeswax comb. The primary tool here is the honey extractor, which uses centrifugal force.

- Tangential Extractors: These hold the frames like spokes in a wheel, extracting from one side at a time. They are often more affordable but require you to flip the frames manually to extract from the second side.

- Radial Extractors: These position frames with the top bar facing outward, allowing honey to be extracted from both sides simultaneously. They are more efficient and better suited for larger operations.

- Manual vs. Motorized: Both extractor types can be powered by a hand crank or an electric motor. Manual is best for small-scale beekeepers, while motorized versions drastically increase efficiency for larger yields.

Stage 2: Straining and Liquefaction

Once extracted, raw honey contains wax cappings and other hive debris. It may also be crystallized. This stage is about cleaning the honey and managing its viscosity.

The primary equipment is the processing tank, often a stainless steel, jacketed tank. This double-walled vessel allows hot water to circulate through the outer jacket, gently heating the honey inside. This liquefies crystals and makes the honey less viscous for easy straining and bottling, without directly scorching it.

Stage 3: Moisture Control and Blending

Honey with a water content above 18% is at risk of fermentation. Commercial producers must manage this for shelf stability. This stage may also involve blending different honey varieties for a consistent product.

- Mixing Tanks: These tanks are equipped with a central stirrer or agitator. The gentle mixing helps create a homogenous blend if combining different honey batches.

- Dehumidifiers: In an integrated plant, a processing unit can perform both mixing and moisture removal. Warm, dry air is passed over the honey's surface to reduce its water content to a safe level.

Stage 4: Pumping and Transfer

Moving a thick, viscous liquid like honey requires specialized equipment. This is the "plumbing" that connects the different stages of your operation.

- Pumps: Sanitary, industrial-grade pumps are used to move honey from extractors to tanks and from tanks to bottling lines.

- Valves and Fittings: All piping, valves, and fittings must be sanitary-grade to prevent contamination and allow for easy cleaning.

Understanding the Trade-offs

Choosing equipment is an exercise in balancing cost, quality, and efficiency. There is no single "best" setup; there is only the best setup for your specific goals.

The Impact of Heat

Heating honey is a contentious topic. Gentle warming in a jacketed tank to liquefy crystals and aid filtering is standard practice and has a minimal impact on quality.

However, high-heat pasteurization, while ensuring a long shelf life and preventing crystallization, can degrade the delicate enzymes and volatile aromatic compounds that define raw honey's unique character.

Operational Scale and Labor

The jump from a manual, hobbyist setup to a motorized, semi-automated one is significant. A motorized extractor and a simple pump can save dozens of hours of labor, but it represents a major capital investment. Your scale of operation is the single most important factor in this decision.

Maintenance and Hygienic Design

Honey is a food product, and cleanliness is paramount. Equipment with a hygienic design, such as Clean-In-Place (CIP) or Clean-Out-of-Place (COP) tanks, simplifies sanitization. Cheaper equipment may have seams or components that are difficult to clean, posing a contamination risk.

Making the Right Choice for Your Goal

Your equipment purchasing strategy should directly reflect your primary objective.

- If your primary focus is small-scale, hobbyist production: A manual tangential extractor and a food-grade bucket with a simple strainer are all you need to get started.

- If your primary focus is creating a premium, artisanal product: Invest in a motorized radial extractor for efficiency and a small, jacketed tank for gentle liquefaction before bottling.

- If your primary focus is commercial efficiency and shelf stability: A fully integrated system with large mixing tanks, pumps, and potentially pasteurization or dehumidification capabilities is necessary.

By aligning your equipment choices with your specific goals, you transform a simple purchase into a strategic investment in your operation's success.

Summary Table:

| Processing Stage | Key Equipment | Purpose |

|---|---|---|

| Extraction | Tangential/Radial Extractors (Manual/Motorized) | Separate honey from comb using centrifugal force. |

| Straining & Liquefaction | Jacketed Processing Tanks | Gently heat honey to liquefy crystals and strain out debris. |

| Moisture Control & Blending | Mixing Tanks with Agitators; Dehumidifiers | Blend honey batches and reduce water content for shelf stability. |

| Pumping & Transfer | Sanitary Pumps, Valves & Fittings | Move honey efficiently between processing stages. |

Ready to Build Your Ideal Honey Processing System?

As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, hygienic, and scalable equipment you need to maximize efficiency and protect your honey's quality. Whether you're scaling up to a fully automated plant or need a robust motorized extractor, our expert team can help you select the perfect machinery for your operational goals.

Contact HONESTBEE today for a consultation and discover how our wholesale-focused solutions can power your success.

Visual Guide

Related Products

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Professional Long-Handled Silicone Honey Scraper for Beekeeping

People Also Ask

- What are the multipurpose functionalities of a honey press? Versatile Harvesting for Beekeepers & Homesteaders

- How easy is it to clean and maintain the Honey Press? Designed for Quick, Effortless Cleanup

- Why is the use of professional extraction tools like low-pressure suction pumps necessary for harvesting honey? Learn More

- What other materials can a honey press be used for besides honeycomb? Unlock Multi-Purpose Utility

- How can a honey press be used beyond honey extraction? Unlock Its Full Potential for Your Farm