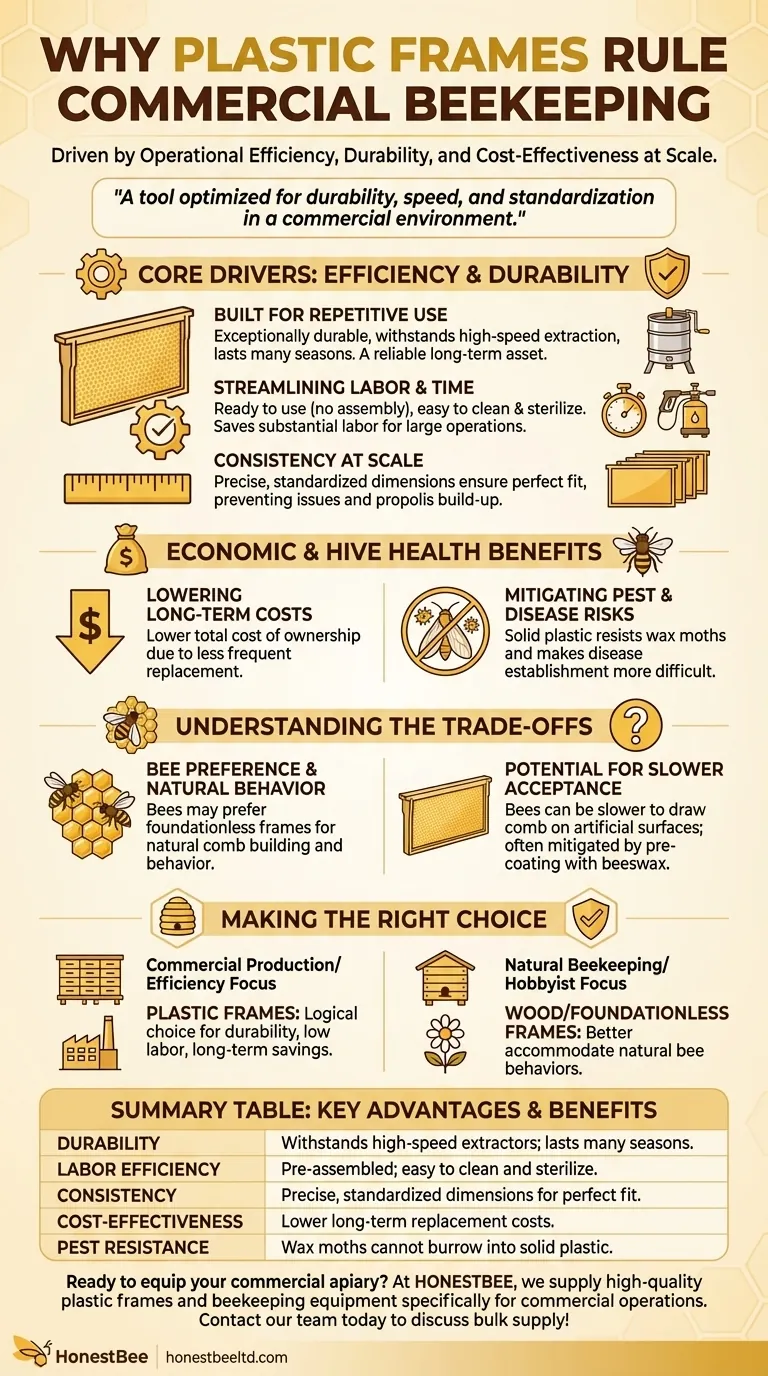

At its core, the widespread adoption of plastic frames in commercial beekeeping is driven by operational efficiency, durability, and cost-effectiveness at scale. These frames are engineered to minimize labor, withstand the rigors of large-scale honey extraction, and reduce long-term replacement costs, making them a pragmatic business decision.

The choice of plastic frames is less about bee preference and more about the economic and logistical realities of managing hundreds or thousands of hives. It is a tool optimized for durability, speed, and standardization in a commercial environment.

The Core Drivers: Efficiency and Durability

For a commercial beekeeper, time is money and equipment failure is a significant liability. Plastic frames are designed to address these realities directly.

Built for Repetitive Use

Plastic is exceptionally durable compared to its wood-and-wax counterpart. It does not break as easily during hive inspections or, more critically, in the high-speed centrifugal extractors used to harvest honey.

This longevity means the frames can last for many seasons, representing a reliable long-term asset rather than a consumable.

Streamlining Labor and Time

Plastic frames come ready to use, eliminating the time-consuming process of assembling wooden frames and embedding wax foundation. For an operation managing thousands of frames, this saved labor is a substantial economic benefit.

Furthermore, cleaning and sterilizing plastic is far simpler. The non-porous surface can be scraped and pressure-washed, reducing the turnaround time between uses.

Consistency at Scale

Plastic frames are mass-produced to precise, standardized dimensions. This consistency ensures a perfect fit in hive bodies and honey supers, preventing issues like improper spacing or frames getting stuck together with propolis.

Economic and Hive Health Considerations

Beyond the physical advantages, plastic frames offer clear financial and pest management benefits that are critical for a commercial business.

Lowering Long-Term Costs

While the initial cost can be competitive, the true economic advantage comes from a lower total cost of ownership. Their resistance to damage and pests like wax moths means they need to be replaced far less frequently than wooden frames.

Mitigating Pest and Disease Risks

The wax moth, a significant pest, cannot burrow into and destroy solid plastic frames as it can with wax foundation. This inherent resistance protects the beekeeper's equipment investment.

The non-porous material also makes it more difficult for certain diseases and pests to establish themselves, potentially slowing their spread within a hive or apiary.

Understanding the Trade-offs

The choice of plastic is not without its compromises. What works for a large-scale commercial operation is not always ideal from the perspective of the bees themselves.

Bee Preference and Natural Behavior

Research and observation show that bees often prefer to build their own comb from scratch on foundationless frames. This allows them to engage in natural "festooning" behavior, where they hang in chains to construct the comb.

A plastic foundation acts as a barrier, forcing the bees to work on two separate surfaces. While effective, it doesn't fully align with their innate building instincts.

Potential for Slower Acceptance

Because it is an artificial surface, bees may sometimes be slower to draw out comb on new plastic frames compared to frames with natural beeswax foundation. Commercial beekeepers often mitigate this by pre-coating the frames with a thin layer of beeswax.

Making the Right Choice for Your Apiary

The decision between plastic, wood, or foundationless frames hinges entirely on your specific goals as a beekeeper.

- If your primary focus is commercial production or maximizing efficiency: Plastic frames are the logical choice for their durability, low labor requirements, and long-term cost savings.

- If your primary focus is natural beekeeping or hobbyist observation: Wood frames with wax foundation or foundationless frames better accommodate the bees' natural behaviors.

Ultimately, understanding why the professionals make their choices empowers you to select the right tool for your own unique beekeeping journey.

Summary Table:

| Key Advantage | Benefit for Commercial Beekeepers |

|---|---|

| Durability | Withstands high-speed extractors; lasts many seasons. |

| Labor Efficiency | Pre-assembled; easy to clean and sterilize. |

| Consistency | Precise, standardized dimensions for perfect fit. |

| Cost-Effectiveness | Lower long-term replacement costs. |

| Pest Resistance | Wax moths cannot burrow into solid plastic. |

Ready to equip your commercial apiary with durable, time-saving solutions?

At HONESTBEE, we supply high-quality plastic frames and beekeeping equipment designed specifically for the demands of commercial operations and distributors. Our wholesale-focused approach ensures you get the reliable, standardized equipment you need to maximize efficiency and profitability.

Contact our team today to discuss your bulk supply needs and discover how we can support your business growth.

Visual Guide

Related Products

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Assembled Wooden Bee Frames with Plastic Foundation for Durability and Convenience by HONESTBEE

- Plastic Honey Comb Frames Cassette Box for Honey

- Heavy-Duty Stainless Steel Clip-On Frame Perch

People Also Ask

- What are the mechanical and acoustic characteristics of a one-piece plastic frame and foundation? Strength vs. Sound

- Can you boil plastic bee frames? Avoid This Costly Mistake and Protect Your Hive

- Can beekeepers switch between wooden and plastic frames? Optimize Your Hive's Performance

- Are plastic frames good? Boost Apiary Efficiency with Durable, Pest-Resistant Frames

- What are the advantages of plastic frames for beehives? Boost Apiary Efficiency & Durability