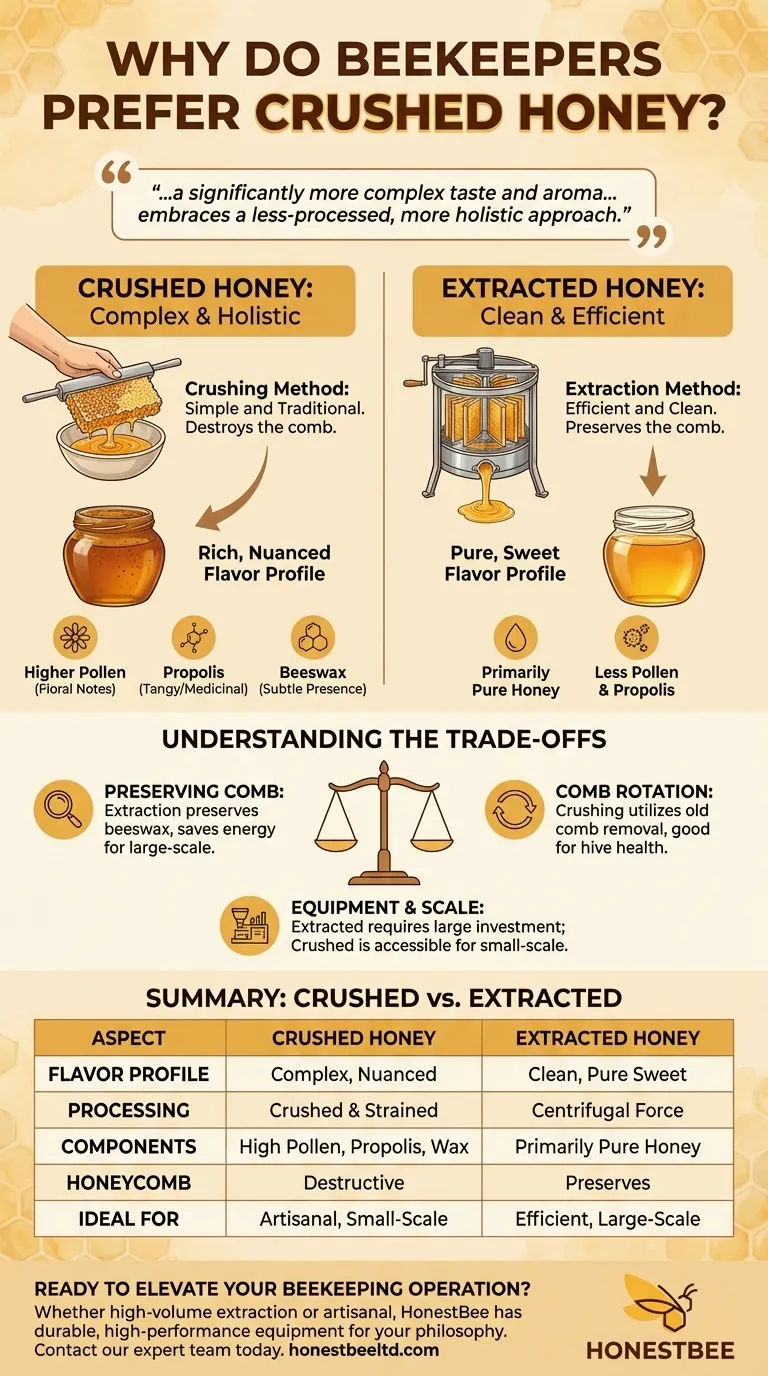

The preference for crushed honey among many beekeepers stems from its significantly more complex taste and aroma. Unlike honey spun out in an extractor, which is a very clean process, crushing the comb releases not just the honey but also more of the pollen, propolis, and beeswax, resulting in a product with a richer and more nuanced flavor profile that reflects the complete essence of the hive.

The core reason for preferring crushed honey is not just about taste—it's about a processing philosophy. This method embraces a less-processed, more holistic approach that captures a wider spectrum of the hive's natural components in the final product.

Understanding the Extraction Methods

To grasp why crushed honey is different, it's essential to compare the two primary methods of extraction: crushing versus centrifugal force.

The Crushing Method: Simple and Holistic

Crushing is a traditional and straightforward process. Beekeepers simply take the honeycomb, cut it from the frames, and press or crush it.

The honey is then strained to remove the larger pieces of beeswax, but microscopic particles of pollen, propolis, and wax remain suspended in the final product. This method is inherently destructive to the honeycomb.

The Extraction Method: Efficient and Clean

Most commercial honey is produced using a centrifugal extractor. A heated knife first uncaps the wax-sealed cells.

The frames are then placed in a spinner that uses centrifugal force to sling the honey out of the cells while leaving the delicate wax comb itself intact. This is a far more efficient method, especially at scale.

The Impact on Flavor and Quality

The extraction method directly influences the final product's characteristics, from taste to texture.

Why Crushing Creates Complexity

The "complex taste" mentioned by beekeepers comes from the additional elements that make their way into the honey. Pollen carries the distinct floral notes of the plants the bees visited, while propolis (a resinous bee-made substance) can add subtle, slightly tangy or medicinal notes. These elements are present in much higher concentrations than in extracted honey.

Why Extraction Creates Clarity

Centrifugal extraction is a "cleaner" process by design. It is engineered to separate the honey from everything else. The resulting product is clearer, more uniform, and has a pure, sweet flavor without the added complexity from other hive components.

Understanding the Trade-offs

Neither method is universally "better"; they serve different goals and scales of operation. The choice involves a clear set of trade-offs for the beekeeper.

The Value of Preserving Comb

The primary advantage of centrifugal extraction is that it preserves the honeycomb. Bees expend a tremendous amount of energy to produce wax and build comb. Reusing this comb saves the colony significant resources, allowing them to produce more honey more quickly. For this reason, extraction is the standard for nearly all large-scale beekeeping.

The Role of Comb Rotation

However, beekeepers must regularly rotate out old honeycomb for the health of the colony. Old, dark comb can accumulate contaminants and pathogens. For beekeepers who are already planning to cycle out old frames, the destructive nature of the crushing method aligns perfectly with good hive management practices.

Equipment and Scale

A honey extractor is a significant financial investment and requires space. The crush-and-strain method requires minimal equipment, making it highly accessible for hobbyists or small-scale apiarists who prioritize product character over production volume.

Making the Right Choice for Your Goal

Understanding the difference between these methods empowers you to choose the honey that best suits your preference.

- If your primary focus is a complex, artisanal flavor: Seek out honey labeled as "crushed," "pressed," or simply "comb honey" to experience the full, nuanced profile of the hive.

- If your primary focus is a clean, clear, and consistently sweet product: Standard extracted honey, which makes up the vast majority of the market, is an excellent and reliable choice.

Ultimately, knowing how your honey was processed deepens your appreciation for the final product and the beekeeper's craft.

Summary Table:

| Aspect | Crushed Honey | Extracted Honey |

|---|---|---|

| Flavor Profile | Complex, nuanced, rich | Clean, pure, consistently sweet |

| Processing Method | Comb is crushed and strained | Centrifugal force in an extractor |

| Key Components | Higher levels of pollen, propolis, beeswax | Primarily pure honey |

| Honeycomb | Destructive to the comb | Preserves the comb for reuse |

| Ideal For | Artisanal, small-scale production | Efficient, large-scale production |

Ready to Elevate Your Beekeeping Operation?

Whether you're a commercial apiary focused on high-volume extraction or a distributor seeking artisanal supplies, HONESTBEE has the right equipment for your philosophy. We supply durable, high-performance beekeeping supplies and equipment through wholesale-focused operations.

Let's discuss how we can support your specific goals. Contact our expert team today to find the perfect solutions for your hive management and honey production needs.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What are the key features of the Crush & Strain honey extraction method? A Simple, Low-Cost Approach

- What materials are needed to construct a basic manual honey press? DIY Guide for Efficient Extraction

- What are the advantages of using a honey press? Affordable, Versatile Harvesting for Small-Scale Beekeepers

- What are the functions of mechanical honey presses and melting separation equipment? Optimize Your Honey Extraction

- What are the different methods for filtering honey extracted from a press? Optimize Clarity and Quality

- What is the role of mechanical honey pressing and processing machinery in improving honey quality? Master Honey Purity

- What is the role of dense synthetic filters in beeswax refining? Achieve Microscopic Purity and Market-Ready Quality

- What is the technical necessity of beeswax extractors? Unlock High-Value Beekeeping Byproducts for Global Markets