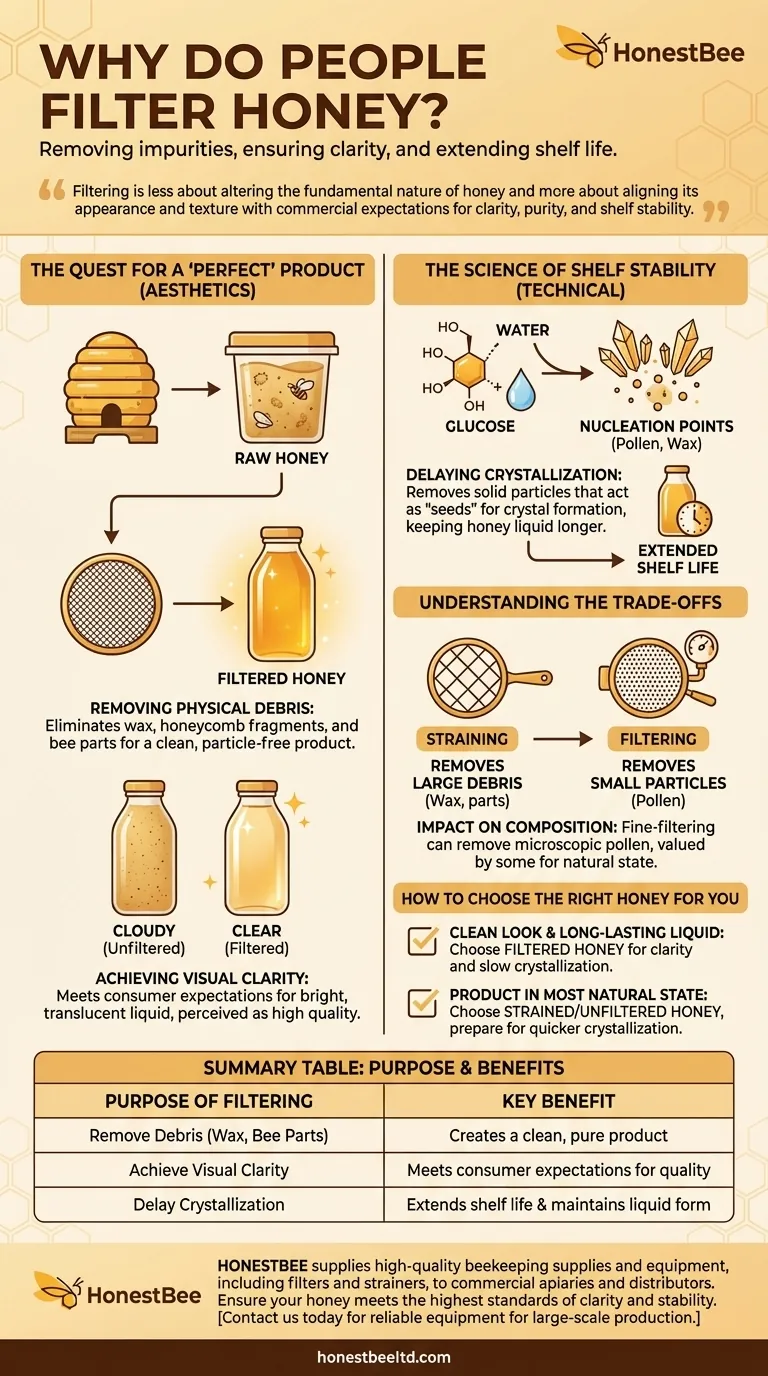

The primary reasons for filtering honey are to remove visible impurities like wax and bee parts, to create the clear and smooth appearance most consumers expect, and to slow down the natural process of crystallization. This processing step is driven by both aesthetic standards and the commercial need for a stable, long-lasting product on the shelf.

Filtering is less about altering the fundamental nature of honey and more about aligning its appearance and texture with commercial expectations for clarity, purity, and shelf stability.

The Quest for a "Perfect" Product

The journey from the beehive to the bottle often involves steps designed to make the final product more appealing and consistent for the average consumer. Filtering is a central part of this process.

Removing Physical Debris

Raw honey, straight from the hive, contains more than just honey. It's a mix that includes bits of beeswax, fragments of honeycomb, and sometimes even bee parts like legs or wings.

Filtering serves as a crucial quality control step, ensuring these "foreign-looking materials" are removed before bottling. This guarantees a clean product free from unwanted particles.

Achieving Visual Clarity

For better or worse, perception is reality in a retail environment. Consumers have been conditioned to associate high-quality honey with a bright, translucent, and perfectly clear liquid.

Cloudy or opaque honey containing small specks can be misinterpreted as being old, contaminated, or of poor quality. Filtering produces that crystal-clear look that many buyers find appealing and trustworthy.

The Science of Shelf Stability

Beyond aesthetics, filtering has a significant technical purpose that directly impacts the honey's texture and shelf life.

Delaying Crystallization

Crystallization is a natural process where the glucose in honey separates from water and forms tiny crystals. This makes the honey thick, grainy, and difficult to pour.

Small, solid particles—such as bits of wax or even pollen grains—act as nucleation points, or starting seeds, for crystals to form around. By filtering these particles out, you remove the triggers for crystallization, keeping the honey in a liquid state for much longer.

Understanding the Trade-offs

While filtering creates a more commercially viable product, it's essential to understand what is being changed in the process.

Filtering vs. Straining

These terms are often used interchangeably, but they represent different levels of processing. Straining typically involves passing honey through a mesh to remove large debris like beeswax and bee parts.

Filtering, on the other hand, can involve pushing honey under pressure through very fine filters. This not only removes debris but can also remove much smaller particles, which some argue are a natural part of the honey.

The Impact on Composition

The main debate around filtering centers on what is removed alongside the undesirable debris. Aggressive, fine-filtering methods can potentially strip out some of the microscopic pollen grains.

While these particles have a negligible impact on the honey's nutritional value, their presence is valued by those seeking a product that is as close to its natural state as possible.

How to Choose the Right Honey for You

Your choice depends entirely on what you value in the final product.

- If your primary focus is a clean look and long-lasting liquid texture: Choose filtered honey for its clarity and slow crystallization.

- If your primary focus is a product in its most natural state: Choose "strained" or "unfiltered" honey, and be prepared for it to crystallize more quickly.

Ultimately, understanding why honey is filtered empowers you to choose the product that best aligns with your personal preference for either a polished appearance or a more rustic character.

Summary Table:

| Purpose of Filtering | Key Benefit |

|---|---|

| Remove Debris (Wax, Bee Parts) | Creates a clean, pure product |

| Achieve Visual Clarity | Meets consumer expectations for quality |

| Delay Crystallization | Extends shelf life and maintains liquid form |

HONESTBEE supplies high-quality beekeeping supplies and equipment, including filters and strainers, to commercial apiaries and distributors. Ensure your honey meets the highest standards of clarity and stability. Our wholesale-focused operations provide the reliable equipment you need for efficient, large-scale production. Contact us today to discuss your supply needs!

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- Why is the use of dry sieves and storage containers critical? Prevent Honey Fermentation and Spoilage

- How much honey can a honey dryer process and by what percentage does it reduce moisture? Optimize Your Honey Production

- What are the processing advantages of using industrial dehumidification equipment for high-moisture tropical honey?

- What are some methods to prevent fermentation in high-moisture honey? Protect Your Honey's Quality and Value

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation