At its core, a honey bucket warmer is a valuable tool because it provides gentle, uniform, and controlled heat. This allows you to safely liquefy crystallized honey and maintain its ideal viscosity for bottling, all without destroying its delicate enzymes, flavor, and color.

The fundamental challenge with honey is not simply heating it, but heating it safely. A honey bucket warmer is the definitive solution, designed specifically to prevent the overheating and "hot spots" that permanently damage honey's quality.

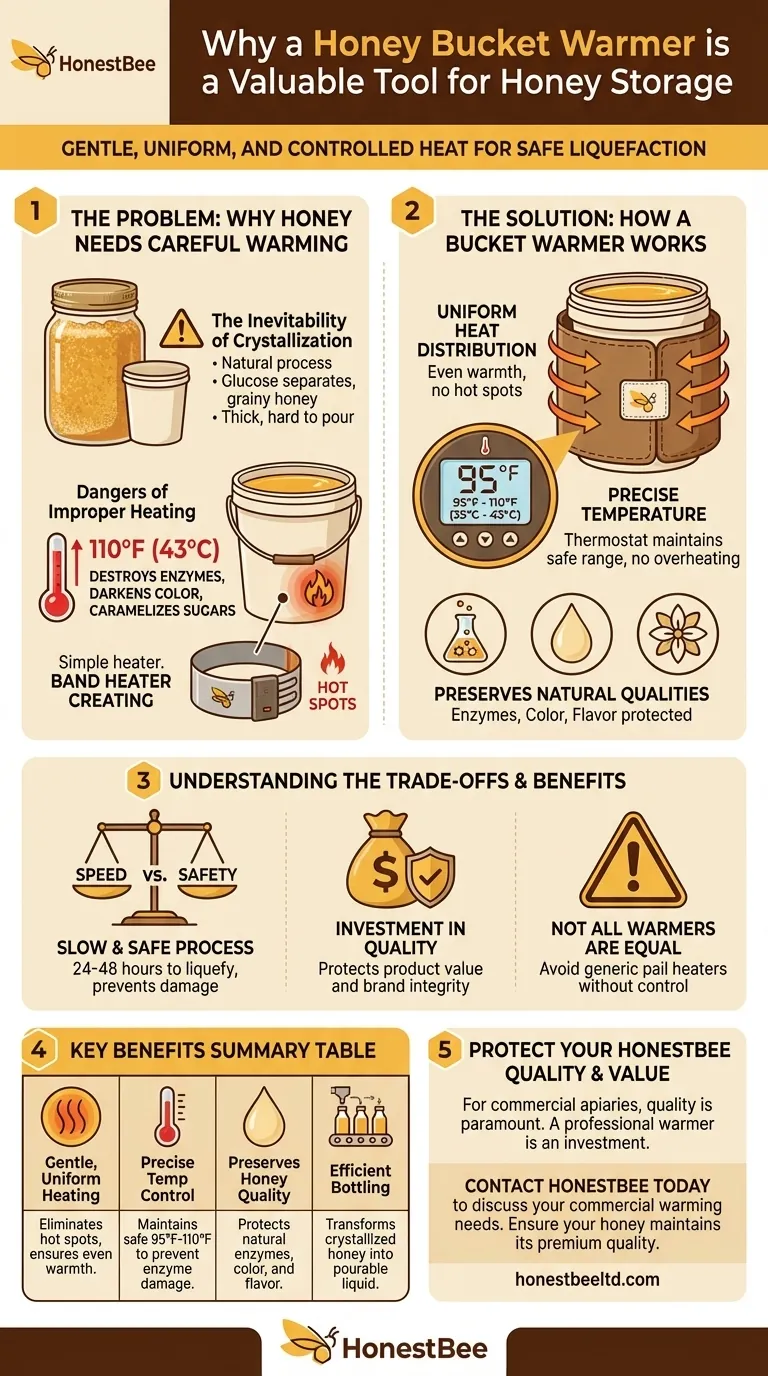

The Core Problem: Why Honey Needs Careful Warming

To understand the value of a bucket warmer, you must first understand the fragile nature of honey. It is a sensitive product that can be easily degraded by improper handling.

The Inevitability of Crystallization

Crystallization is a completely natural process in which the glucose in honey separates from water and forms solid crystals. It is a sign of pure, unprocessed honey, not spoilage.

However, once crystallized, the honey becomes thick, grainy, and nearly impossible to pour, filter, or bottle.

The Dangers of Improper Heating

The most common mistake is applying too much heat too quickly. High temperatures (typically above 110°F or 43°C) will permanently destroy the beneficial enzymes, such as diastase and invertase, that define raw honey.

Overheating also darkens the honey's color and can caramelize its natural sugars, fundamentally altering its delicate flavor profile. This damage is irreversible.

The Issue with "Hot Spots"

Using uncontrolled heat sources, like a simple heating band or a hot water bath, creates "hot spots." Even if the average temperature seems safe, pockets of intense heat can form against the bucket wall, scorching and degrading the honey in those areas.

How a Honey Bucket Warmer Solves the Problem

A purpose-built honey bucket warmer is engineered to counteract these specific risks through its design and functionality.

Gentle, Uniform Heat Distribution

Unlike simple band heaters, a full-coverage bucket warmer wraps around the entire container. It uses a low-wattage heating element spread over a large surface area to distribute warmth evenly.

This design is the key to eliminating the dangerous hot spots that scorch honey and ruin its quality.

Precise Temperature Control

Professional-grade honey warmers include an integrated thermostat. This allows you to set and maintain a precise temperature, typically between 95°F and 110°F (35-43°C).

The warmer will cycle on and off to hold this temperature, ensuring the honey is warmed gently and never overheated. This provides reliable, set-and-forget control over the liquefaction process.

Preserving Honey's Natural Qualities

By combining uniform heat with precise temperature control, the warmer liquefies crystallized honey while keeping it below the thermal damage threshold.

This preserves the honey's natural enzymes, light color, and delicate aromatic compounds, maintaining the quality and value of the final product.

Understanding the Trade-offs and Considerations

While highly effective, it's important to approach this tool with the right expectations.

Speed vs. Safety

A honey bucket warmer is designed for safety, not speed. The process of gently and safely liquefying a full 5-gallon bucket of crystallized honey can take 24 to 48 hours.

This slow, patient approach is a feature, not a flaw. It is the only way to ensure the entire volume is liquefied without any part of it being damaged by excessive heat.

The Cost as an Investment

A quality honey warmer is a significant investment compared to DIY methods. However, for anyone selling honey or managing a serious hobby, the cost is an insurance policy.

It protects the value of your product and the integrity of your brand by guaranteeing a consistent, high-quality output every time.

Not All Warmers Are Equal

Be wary of generic "pail heaters" or simple heating bands without thermostatic control. A true honey warmer offers full-bucket coverage and the ability to set a specific, low temperature to ensure the honey is protected.

Making the Right Choice for Your Honey

Your goal determines the right approach to managing your honey's temperature.

- If your primary focus is preserving raw honey's full enzymatic value: A thermostat-controlled bucket warmer is non-negotiable for liquefying honey while keeping it below the damage threshold.

- If your primary focus is efficient bottling and commercial processing: A bucket warmer is an essential tool for maintaining a consistent, pourable viscosity without degrading product quality.

- If you are a small-scale hobbyist with occasional needs: You can attempt DIY methods like a warming cabinet, but you must constantly monitor the temperature and accept the high risk of accidentally overheating and damaging your honey.

Ultimately, using the right tool gives you complete control over your honey's quality from the hive to the jar.

Summary Table:

| Key Benefit | Description |

|---|---|

| Gentle, Uniform Heating | Eliminates dangerous hot spots that scorch honey, ensuring even warmth distribution. |

| Precise Temperature Control | Thermostat maintains a safe temperature (95°F-110°F / 35°C-43°C) to prevent enzyme damage. |

| Preserves Honey Quality | Protects natural enzymes, color, and flavor profile, maintaining the value of raw honey. |

| Efficient Bottling | Transforms crystallized honey into a pourable liquid for easy filtering and packaging. |

Protect Your Honey's Quality and Value with the Right Equipment

For commercial apiaries and beekeeping equipment distributors, the quality of your final product is paramount. A professional honey bucket warmer is not just a tool; it's an investment in product integrity and brand consistency.

HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and equipment you need to operate efficiently at scale. We help you safeguard your honey's delicate properties from the hive to the jar.

Contact HONESTBEE today to discuss your commercial warming needs and ensure your honey maintains its premium quality.

Visual Guide

Related Products

- HONESTBEE Commercial Upright Honey Melter

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- How can crystallized honey be restored to a liquid state? A Beekeeper's Guide to Gentle Re-liquefaction

- What is the recommended temperature range for heating honey? Protect Quality with Precise Thermal Control

- How do controlled heat treatment devices achieve disinfection of contaminated beehives? Chemical-Free Hive Sterilization

- What is the primary function of honey heating equipment? Achieve Precise Decrystallization & Quality Preservation

- How does temperature affect the storage of honey? Expert Tips for Maintaining Quality and Texture

- How does the performance of honey heat treatment equipment impact HMF levels? Optimize Precision for Quality Control

- What temperature can raw honey be heated to? Preserve Enzymes and Avoid Degradation

- Why is temperature-controlled industrial equipment required for processing honey bee feeding syrup? Ensure Hive Safety