In short, quality honey processing equipment is the critical link between a healthy beehive and a premium, marketable product. This equipment is vital for maintaining honey's purity and natural qualities, boosting production efficiency, and ensuring the final product is safe for consumers. It directly impacts your operational capacity and the reputation of your brand.

Investing in quality processing equipment is not merely an operational upgrade; it's a strategic decision that directly protects product integrity, elevates production capacity, and builds consumer trust. It transforms raw honey into a consistent, safe, and premium food product.

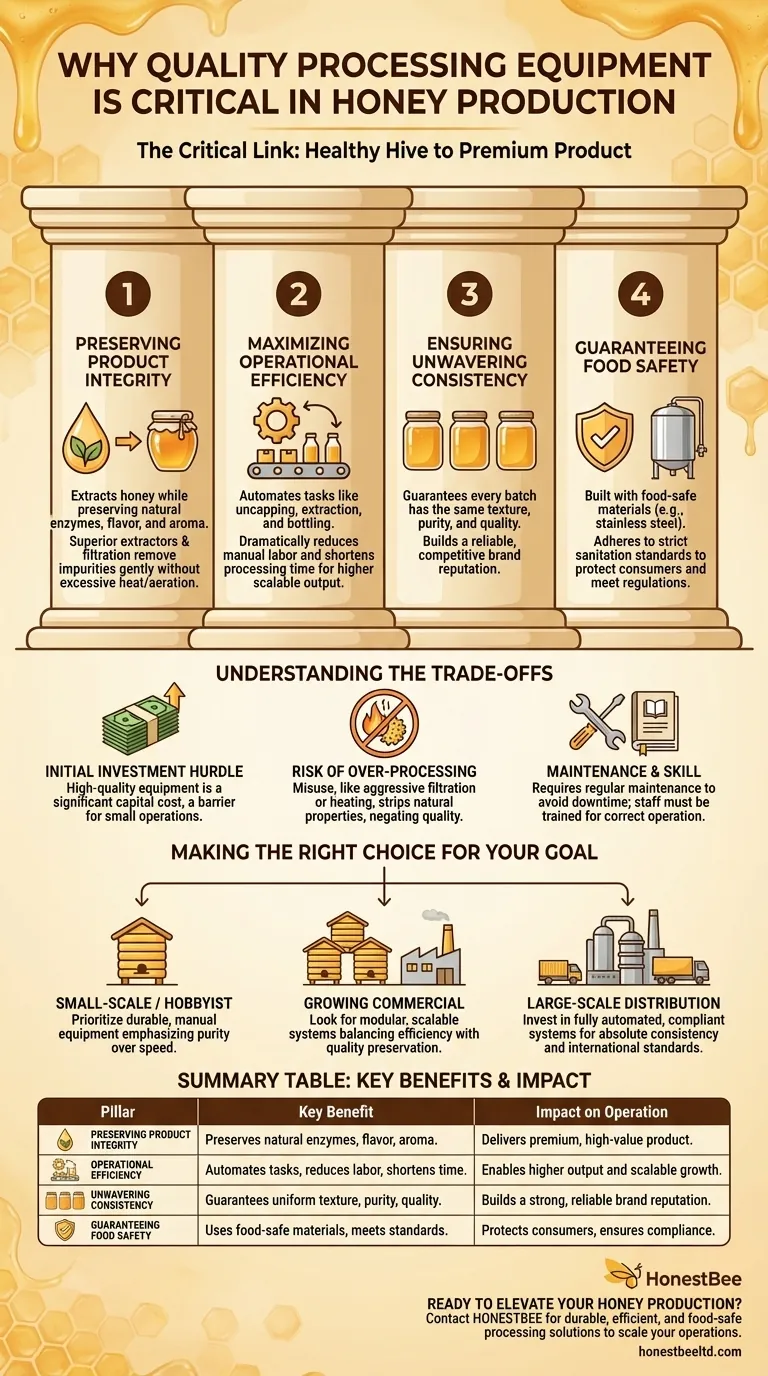

The Core Functions of Processing Equipment

The journey from honeycomb to jar involves several critical steps. Quality equipment ensures each stage enhances, rather than degrades, the final product.

Pillar 1: Preserving Product Integrity

The primary goal of processing is to extract honey while preserving its natural enzymes, flavor, and aroma. High-quality equipment is designed for this delicate task.

Superior extractors and filtration systems are engineered to effectively remove impurities like wax cappings and debris without introducing excessive heat or aeration, which can degrade the honey's beneficial properties.

Pillar 2: Maximizing Operational Efficiency

Manual honey processing is laborious and time-consuming. Modern equipment automates key tasks, leading to significant gains in productivity.

Automated systems for uncapping, extraction, and bottling dramatically reduce manual labor and shorten the overall processing time. This allows for higher output without compromising the quality of the product, enabling an operation to scale effectively.

Pillar 3: Ensuring Unwavering Consistency

For any commercial producer, consistency is key to building a loyal customer base. Batch-to-batch variation can damage a brand's reputation.

Proper equipment ensures that every jar of honey has the same texture, purity, and quality. This reliability makes the product more dependable and ready for competitive retail markets.

Pillar 4: Guaranteeing Food Safety

Honey is a food product, and as such, it is subject to strict health and sanitation standards.

Professional-grade equipment is built with food-safe materials, like stainless steel, and designed for easy and thorough cleaning. This adherence to sanitation standards is non-negotiable for protecting consumer health and avoiding regulatory issues.

Understanding the Trade-offs

While the benefits are clear, a pragmatic approach requires acknowledging the associated challenges. Investing in quality equipment is a significant decision with direct implications.

The Initial Investment Hurdle

The most obvious trade-off is cost. High-quality, durable, and efficient processing equipment represents a significant capital investment, which can be a barrier for smaller or emerging operations.

The Risk of Over-Processing

Even the best equipment can be misused. For example, aggressive filtration or excessive heating to speed up bottling can strip honey of its natural pollen and beneficial enzymes, effectively defeating the purpose of preserving its quality.

Maintenance and Operational Skill

Advanced machinery requires regular maintenance to function reliably. Neglecting this can lead to unexpected downtime during the critical processing season, negating the benefits of efficiency. Staff must also be trained to operate the equipment correctly.

Making the Right Choice for Your Goal

The "right" equipment depends entirely on the scale and objective of your operation.

- If your primary focus is small-scale or hobbyist production: Prioritize durable, easy-to-clean manual equipment that emphasizes purity and product quality over high-speed automation.

- If your primary focus is a growing commercial operation: Look for modular, scalable systems that balance efficiency gains with the essential task of maintaining the honey's natural characteristics.

- If your primary focus is large-scale distribution: Invest in fully automated, compliant systems that guarantee absolute consistency and meet the highest international food safety standards.

Ultimately, the right equipment empowers you to honor the work of your bees by delivering a product that is pure, safe, and consistently excellent.

Summary Table:

| Pillar | Key Benefit | Impact on Operation |

|---|---|---|

| Product Integrity | Preserves natural enzymes, flavor, and aroma. | Delivers a premium, high-value product. |

| Operational Efficiency | Automates tasks, reduces labor, and shortens processing time. | Enables higher output and scalable growth. |

| Unwavering Consistency | Guarantees uniform texture, purity, and quality batch-to-batch. | Builds a strong, reliable brand reputation. |

| Food Safety | Uses food-safe materials and meets strict sanitation standards. | Protects consumers and ensures regulatory compliance. |

Ready to Elevate Your Honey Production?

For commercial apiaries and beekeeping equipment distributors, the right equipment is a strategic investment in your brand's future. HONESTBEE supplies the durable, efficient, and food-safe processing equipment you need to scale your operations while protecting the natural quality of your honey.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment solutions can boost your efficiency and ensure product excellence.

Visual Guide

Related Products

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What is the difference between radial and tangential honey extractors? Choose the Right Extractor for Your Harvest

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What is the difference between tangential and radial honey extractors? Choose the Right Tool for Your Scale

- What are the advantages of tangential honey extractors? Gentle, Affordable Honey Extraction for Your Apiary

- What is the difference between a radial and tangential honey extractor? Boost Your Harvest Efficiency