In short, a beekeeper chooses a tangential extractor over a radial one primarily to protect the honeycomb. This method is gentler on the delicate wax comb, even though it requires more time and manual effort. By preserving the comb, the beekeeper saves the bees significant energy they would otherwise spend on repairs, allowing them to focus on refilling the cells with honey.

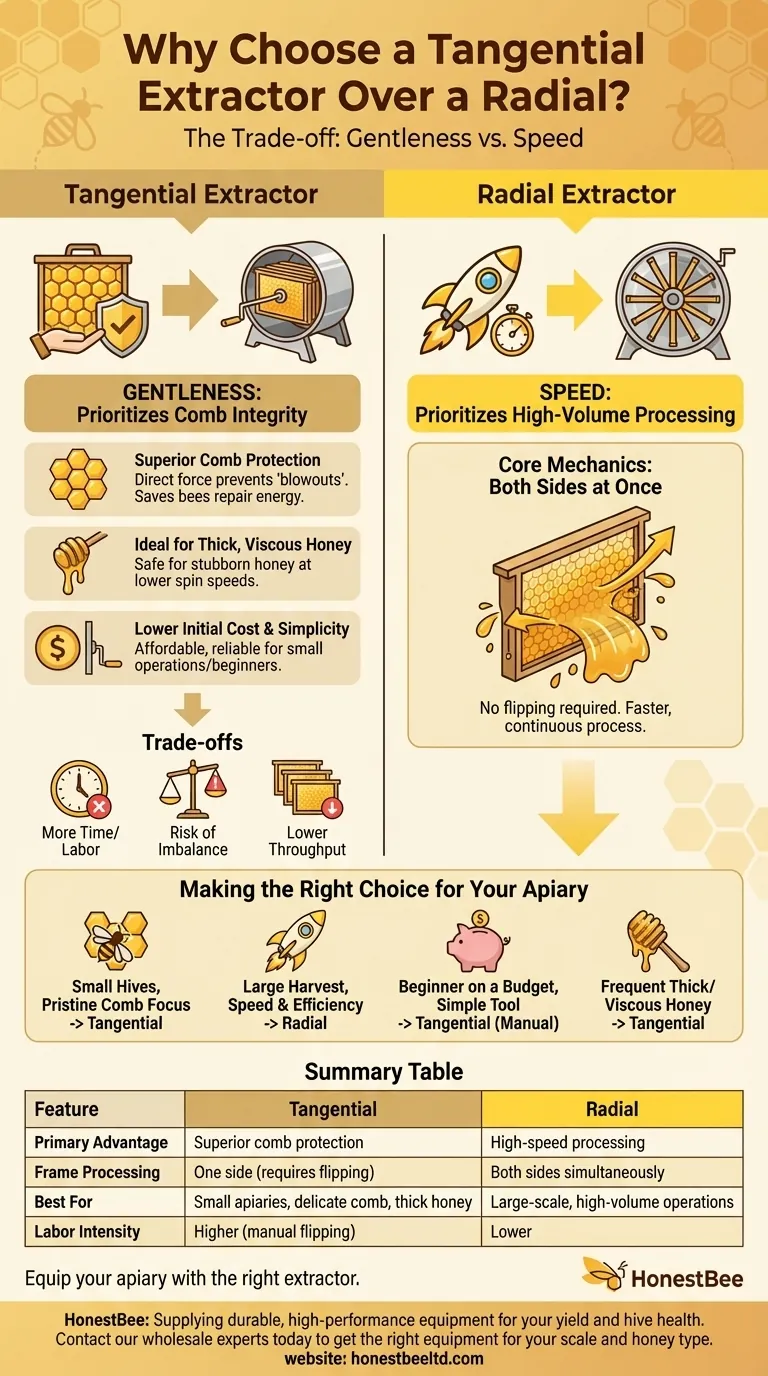

The decision between a tangential and radial extractor boils down to a fundamental trade-off: gentleness versus speed. Tangential extractors prioritize comb integrity at the cost of efficiency, while radial extractors prioritize high-speed, high-volume processing.

The Core Mechanics: Tangential vs. Radial

To understand the choice, you must first understand how each machine works. The difference in frame orientation dictates the entire process.

The Tangential Approach: One Side at a Time

In a tangential extractor, the frames are placed in a basket with one side of the honeycomb facing the outer wall of the drum.

When the basket spins, centrifugal force pulls the honey straight out of the cells on that one side.

To extract honey from the other side, the beekeeper must stop the machine, manually flip each frame, and then spin it again.

The Radial Approach: Both Sides at Once

In a radial extractor, frames are positioned vertically like the spokes of a wheel, with the top bar of the frame facing the outer wall.

As the drum spins, honey is slung out from both sides of the comb simultaneously. This works because honey cells are built with a slight upward angle, and the force acts along this slope.

This design eliminates the need to flip frames, making the process much faster.

The Case for a Tangential Extractor

While slower, the tangential method offers distinct advantages that make it the right choice for many beekeepers, especially those with smaller operations.

Superior Comb Protection

This is the primary reason to choose a tangential model. The force is applied directly outward from the comb, which is the most efficient and least stressful way to remove honey.

This significantly reduces the risk of a "blowout," where the sheer weight of the honey causes the wax comb to tear away from its foundation during extraction.

Less damage means bees can immediately begin refilling the comb, rather than spending days or weeks making repairs.

Ideal for Thick, Viscous Honey

Some types of honey are much thicker and harder to extract. Forcing this viscous honey out requires higher spin speeds.

In a radial extractor, this high speed can easily break fragile comb. The direct, gentle force of a tangential extractor is far safer for the comb, even when dealing with stubborn honey.

Lower Initial Cost and Simplicity

Tangential extractors, particularly the 2-to-4-frame manual crank models, are often the most affordable entry point into honey extraction.

Their simple mechanics make them reliable and easy to use, which is why they are a popular choice for beginners and hobbyists.

Understanding the Trade-offs

The benefits of a tangential extractor come with significant drawbacks in time and labor, which become more pronounced as the size of your apiary grows.

The Time and Labor Commitment

The single biggest disadvantage is the need to flip every frame. For a small harvest of 10 frames, this is a minor inconvenience. For a harvest of 50 or 100 frames, this adds hours of repetitive, manual work.

The Risk of Imbalance

Extracting one full side of honey while the other remains full creates a significant weight imbalance. If not managed carefully, this can cause the extractor to shake violently.

The best practice is a three-step process: partially spin the first side, flip the frames, fully spin the second side, then flip back to finish the first side. While effective, this adds even more time to the process.

Lower Throughput

Tangential extractors generally hold fewer frames than radial extractors of a similar size. Combined with the need for flipping, their overall throughput is much lower, making them unsuitable for large or commercial beekeeping operations.

Making the Right Choice for Your Apiary

Select your equipment based on your specific goals and the scale of your operation.

- If your primary focus is preserving pristine comb and you have a small number of hives: A tangential extractor is the superior choice for its gentle handling.

- If your primary focus is processing a large honey harvest quickly and efficiently: A radial extractor will save you significant time and labor.

- If you are a beginner on a budget and want a simple, reliable tool: A manual, 2-4 frame tangential extractor is an excellent and affordable starting point.

- If you frequently harvest thick, viscous honey that is difficult to extract: The direct force of a tangential extractor provides the best results with the least risk of comb damage.

Ultimately, understanding this core trade-off between speed and gentleness empowers you to select the tool that best aligns with your beekeeping philosophy and operational scale.

Summary Table:

| Feature | Tangential Extractor | Radial Extractor |

|---|---|---|

| Primary Advantage | Superior comb protection | High-speed processing |

| Frame Processing | One side at a time (requires flipping) | Both sides simultaneously |

| Best For | Small apiaries, delicate comb, thick honey | Large-scale, high-volume operations |

| Labor Intensity | Higher (manual flipping) | Lower |

Equip your apiary with the right extractor for your needs.

At HONESTBEE, we understand that the choice between a tangential and radial extractor is crucial for your honey yield and hive health. Whether you're a commercial apiary focused on efficiency or a distributor supplying beekeepers who prioritize comb preservation, we supply the durable, high-performance equipment you need.

Let's discuss the best extraction solution for your operation. Contact our wholesale experts today to get the right equipment for your scale and honey type.

Visual Guide

Related Products

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What is the difference between tangential and radial honey extractors? Choose the Right Tool for Your Scale

- What is a tangential extractor and how does it work? A Complete Guide for Hobbyist Beekeepers

- What is the difference between a radial and tangential honey extractor? Boost Your Harvest Efficiency

- What are the differences between tangential and radial honey extractors? Choose the Right Machine for Your Apiary's Scale