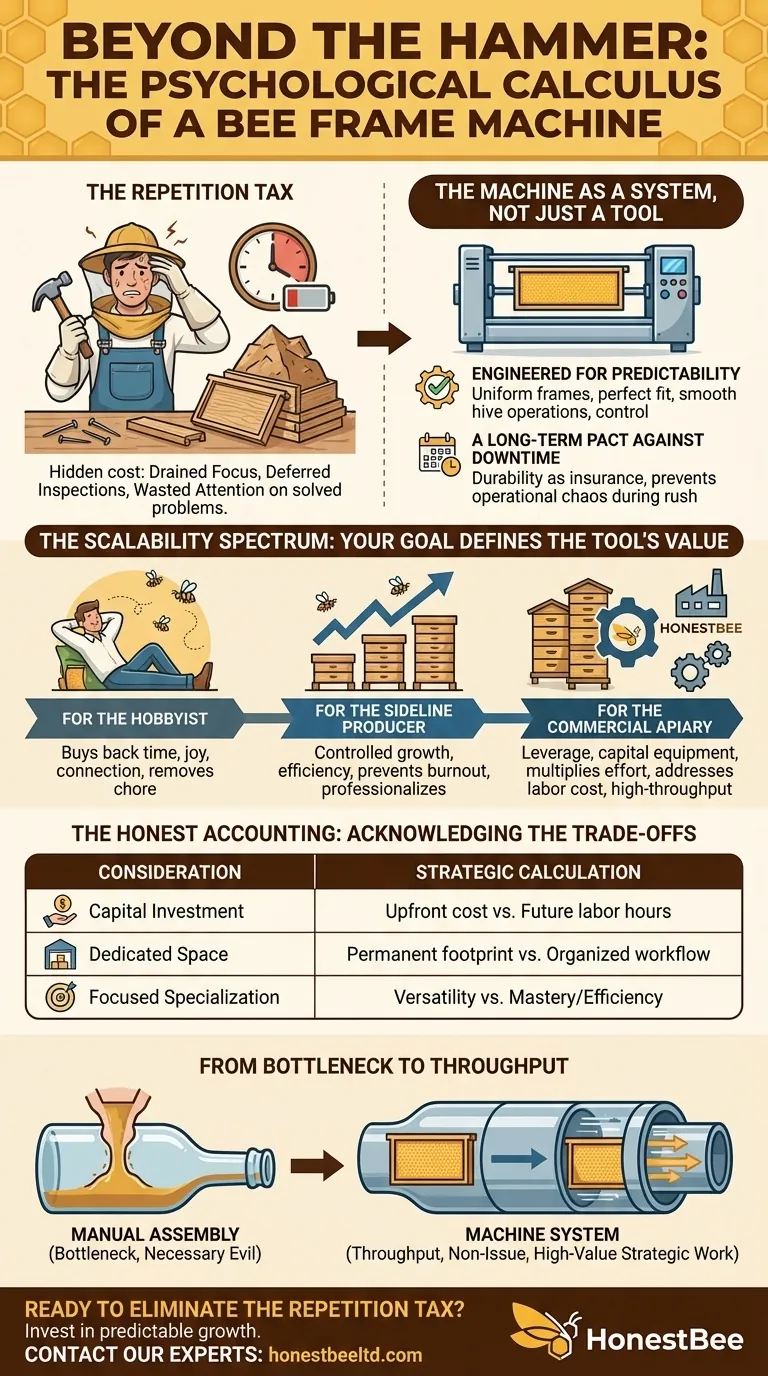

The Repetition Tax

Imagine a workshop in late winter. Stacks of unassembled frame parts—side bars, top bars, bottom bars—form wooden mountains on a workbench. For the beekeeper, this is a familiar ritual: hours spent with a hammer, nails, and glue, meticulously constructing the architecture for the season's honey.

This isn't just a task; it's a tax. The "Repetition Tax" is the hidden cost of performing a simple, monotonous job manually. It's paid not just in hours, but in drained focus, deferred hive inspections, and the nagging feeling that your most valuable resource—your attention—is being spent on a problem that has already been solved.

The Machine as a System, Not Just a Tool

A bee frame forming machine is often described by its physical qualities: robust, durable, and made of high-quality materials. But to see it only as a physical object is to miss the point. Its true value is in the system it creates.

A well-engineered machine is an investment in predictability. It removes the human variable of fatigue and error, creating a system where the output is guaranteed to be consistent, frame after frame.

Engineered for Predictability

The use of high-grade materials isn't for aesthetics; it’s the foundation of a reliable system. Each press, each join, each finished frame is uniform. This standardization isn't a minor detail. It means frames fit perfectly in supers, inspections are smoother, and the hive operates with one less point of friction. It provides the psychological comfort of control in the inherently unpredictable world of agriculture.

A Long-Term Pact Against Downtime

Durability is a promise. It’s a pact between the engineer and the beekeeper that this equipment will not fail during the critical pre-season rush. Downtime in a commercial operation is catastrophic. A machine designed for longevity is a form of insurance against the operational chaos that a broken tool can cause when an entire apiary is waiting for new frames.

The Scalability Spectrum: Your Goal Defines the Tool's Value

The machine’s function is singular, but its purpose is deeply personal and changes with the scale of your ambition.

-

For the Hobbyist: The goal is often joy and connection with nature. The machine buys back time, removing the most industrial chore from the hobby. It preserves the romance of beekeeping by allowing more time to be spent observing the bees, not the workbench.

-

For the Sideline Producer: The goal is controlled growth. This is the inflection point where a hobby starts to look like a business. The machine provides the efficiency to scale hive count without a linear increase in labor, preventing burnout and professionalizing the operation.

-

For the Commercial Apiary: The goal is leverage. Here, the machine is a piece of capital equipment that multiplies human effort. It directly addresses the largest cost center—labor—and transforms a potential production bottleneck into a streamlined, high-throughput process. This is the domain where suppliers like HONESTBEE provide the industrial-grade equipment necessary to operate at scale.

The Honest Accounting: Acknowledging the Trade-offs

No solution is without its considerations. A strategic decision requires acknowledging the trade-offs, not as negatives, but as variables in an equation.

| Consideration | The Strategic Calculation |

|---|---|

| Capital Investment | An upfront cost traded against countless future hours of labor. At what point does your time become more valuable? |

| Dedicated Space | Requires a permanent footprint in the workshop, traded for a more organized and efficient assembly workflow. |

| Focused Specialization | This machine does one thing exceptionally well. It's a trade-off of versatility for mastery and unmatched efficiency. |

This isn't a simple purchase. It's an operational choice based on an honest assessment of your goals, resources, and the true value of your time.

From Bottleneck to Throughput

Ultimately, the calculus of a bee frame forming machine is simple. It reallocates your most finite resource—attention—from a low-value, repetitive task to high-value strategic work like hive health, business growth, and product development.

It transforms frame assembly from a necessary evil into a non-issue. For commercial apiaries and beekeeping equipment distributors, investing in a robust, wholesale-focused solution from HONESTBEE isn't just about building frames faster; it's about building a more resilient, scalable, and profitable operation.

If you're ready to eliminate the repetition tax and invest in a system for predictable growth, we can provide the equipment to make it happen. Contact Our Experts

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Professional Frame Comb Fork and Lifter for Efficient Handling

Related Articles

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- How the Beehive Frame Machine Transforms Apiary Equipment Production

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization

- Unlock Peak Efficiency: The HONESTBEE Bee Frame Machine for Flawless Frame Assembly