Hive Making Machines

Beehive Machine Double End Saw for Precision Hive Component Manufacturing

Item Number : BHES-1

Price varies based on specs and customizations

- Motors

- 2 x 2.2KW

- Board Width

- 350-550 mm

- Output Efficiency

- Approx. 360 pieces/hour

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

HONESTBEE, a dedicated supplier to commercial beeyards and bee equipment distributors, proudly presents our Hive Machine: Double End Saw. This robustly engineered hive machine is designed for the efficient and precise manufacturing of beehive components, ensuring high-quality construction for your apiary needs. This hive machine's straightforward operation, from powering on via its clearly labeled control panel to the precise cutting action on wooden boards.

Design and Construction: A Durable and Professional Hive Machine

The Beehive Machine: Double End Saw boasts a heavy-duty construction designed for longevity and consistent performance in demanding production environments, making it a reliable hive machine for any serious operation.

- Robust Frame: The hive machine is built on a solid, stable frame, painted in a highly visible yellow and black color scheme, indicating its industrial quality and promoting workshop safety.

- Professional Electricals: The electrical components are neatly housed within a dedicated control cabinet, featuring organized wiring and quality contactors and breakers. The external control panel is user-friendly, with clearly labeled buttons for "Motor Start," "Motor Stop," "Start," "Stop," an emergency stop button, and a power indicator light. A prominent "Electric Shock" warning label underscores safety considerations for this powerful hive machine.

- Precision Mechanics: The hive machine utilizes two independent sawing units, each powered by a dedicated motor. These units are mounted on precision linear guides, ensuring smooth and accurate travel for consistent cutting. Protective yellow guards are in place over the cutting areas, as indicated by "WARNING - CAUTION MECHANICAL INJURY" labels, enhancing operator safety. Flexible drag chains (cable carriers) are used to protect and guide wiring and pneumatic lines during movement, contributing to the hive machine's reliability and low maintenance.

Functionality and Operation: Efficient and Accurate Cutting with Your Hive Machine

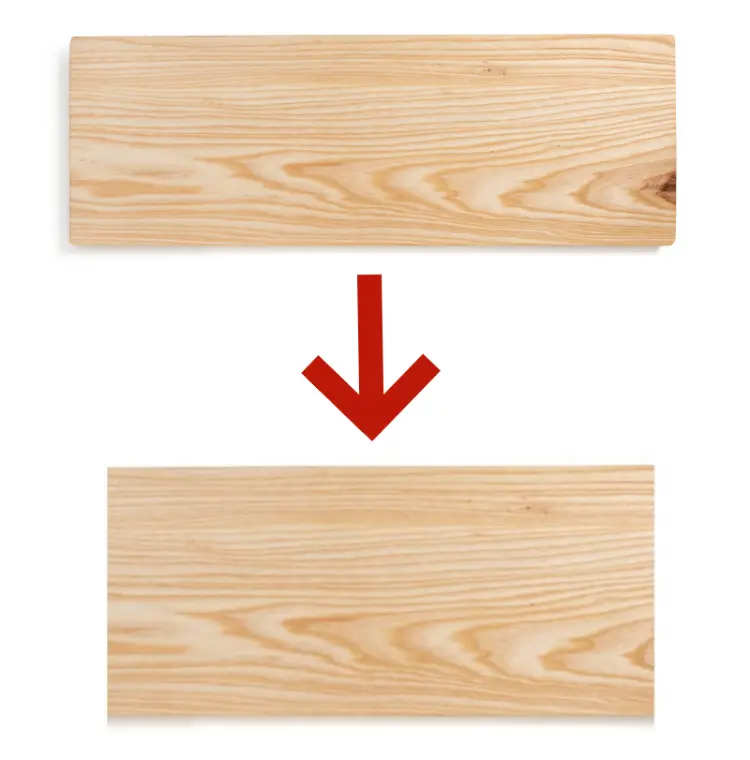

This Double End Saw, a specialized hive machine, is engineered to simultaneously cut both ends of a wooden board to the required length and profile, significantly boosting production efficiency.

- Power & Setup: First ensures the main power is engaged within the electrical cabinet. The hive machine is then powered on using the external control panel.

- Material Clamping: Wooden boards are placed onto the hive machine's worktable. A pneumatic clamping system, featuring robust yellow clamping frames and actuated by pneumatic cylinders, securely holds the workpiece in place during the cutting process. The clamping pressure is adjustable via the pneumatic system.

- Dual-End Cutting: Upon activation via the "Start" button, the two sawing units of this hive machine, each equipped with a high-speed motor (2.2KW per motor) and precision saw blade, simultaneously travel towards the workpiece or the workpiece travels past the saws. This action trims both ends of the board to the precise, predetermined length.

- Output: The finished board is then released by the pneumatic clamps, ready for the next stage of production, with perfectly dimensioned and profiled ends produced by this efficient hive machine.

Key Specifications of this Hive Machine

- Sawing Units: 2, for simultaneous double-end cutting.

- Motors: 2 x 2.2KW high-performance motors.

- Standard Board Width Capacity: 350-550 mm.

- Power Requirements: Three-phase, 380V (standard).

- Pneumatic System: Requires air pressure ≥0.7 MPa (air pump to be provided by customer).

- Output Efficiency: Approximately 360 pieces per hour.

- Safety Features: Emergency stop button, protective guarding, electrical safety warnings, secure pneumatic clamping.

Advantages and Application of Your Hive Machine

The HONESTBEE Double End Saw hive machine offers significant advantages for beehive manufacturers:

- Precision & Consistency: Delivers accurately cut and profiled components every time, ensuring perfect fit-up for beehive boxes and frames. The finger joints produced by this hive machine are clean and precise.

- High Efficiency: Dual cutting heads dramatically reduce processing time compared to single-end operations, with an output of up to 360 pieces per hour.

- Durability & Reliability: Robust construction, quality motors, and protected wiring ensure a long service life with minimal downtime for your hive machine.

- Ease of Operation: The intuitive control panel and pneumatic clamping system simplify operation.

- Versatility: Ideal for producing various beehive components like hive bodies, supers, and frame parts from wooden boards using this versatile hive machine.

Application Scenarios: This hive machine is perfectly suited for:

- Commercial beekeeping operations that manufacture their own hives.

- Dedicated beehive manufacturing workshops.

- Suppliers of wooden beehive kits and components.

- Woodworking shops looking to specialize in or expand into apiary products.

Customization and Support: Tailored Hive Machine Solutions

Understanding that different operations have unique requirements, HONESTBEE offers customization options for your hive machine:

- Adjustable Cutting Width: While standardly accommodating boards from 350-550 mm wide, the hive machine's cutting width can be customized to meet specific client needs.

- Voltage Customization: The machine can be configured for three-phase 220V power supply upon request, catering to different regional electrical standards.

After-Sales Support & Spare Parts: HONESTBEE is committed to long-term customer satisfaction. We provide comprehensive after-sales support for your hive machine, including the provision of necessary spare parts and components to ensure your machine continues to operate at peak efficiency.

Higher Throughput Option: For operations requiring even greater output, HONESTBEE also offers a "Four End Saw" model, another advanced hive machine capable of processing all four sides of a board for enhanced productivity.

Summary: Beehive Machine (Double End Saw)

| Feature | Specification / Benefit |

|---|---|

| Product Name | Beehive Machine: Double End Saw (Hive Machine) |

| Primary Function | Simultaneously cuts and profiles both ends of wooden boards for beehive components. |

| Construction | Heavy-duty steel frame, professional electricals, precision linear guides. |

| Motors | 2 x 2.2KW |

| Board Width | 350-550 mm (Standard); Customizable |

| Power Supply | 3-Phase 380V (Standard); 3-Phase 220V (Customizable) |

| Air Pressure | ≥0.7 Mpa (Customer-supplied air pump) |

| Output Efficiency | Approx. 360 pieces/hour |

| Key Operations | Pneumatic clamping, dual synchronized sawing. |

| Safety | E-stop, protective guards, electrical warnings. |

| Target Customers | Commercial beeyards, beehive manufacturers, bee equipment distributors. |

| Key Advantages | Precision, high efficiency, durability, customization, ease of use. |

| Customization | Cutting width, voltage for your specific hive machine needs. |

| After-Sales | Spare parts and support available for your hive machine. |

| High-Volume Option | Four End Saw hive machine available for increased capacity. |

Invest in Efficiency and Quality for Your Beehive Production with a HONESTBEE Hive Machine

For commercial beeyards and beehive component manufacturers looking to scale production, improve consistency, and reduce labor costs, the HONESTBEE Beehive Machine: Double End Saw is an invaluable asset. Its robust design, precision engineering, and customizable features ensure this hive machine meets the rigorous demands of your operation.

Contact HONESTBEE today to discuss your specific requirements, request a quote, or learn more about how our Double End Saw hive machine can revolutionize your beehive manufacturing process!

4.8

out of

5

This saw is a game-changer! Precision cuts every time, and it arrived faster than expected.

4.9

out of

5

Worth every penny! The durability is unmatched, and it’s so easy to use.

4.7

out of

5

Incredible quality! My hive components have never looked better. Highly recommend!

4.9

out of

5

Fast delivery and top-notch performance. This saw is a must-have for beekeepers!

4.8

out of

5

Love the precision! Makes my work so much easier and faster. Great value!

4.7

out of

5

Solid build and excellent craftsmanship. A reliable tool for any beekeeper.

4.9

out of

5

Super impressed! The saw is sturdy and delivers flawless cuts every time.

4.8

out of

5

Perfect for precision work! The speed and accuracy are outstanding.

4.9

out of

5

A fantastic investment! The saw is durable and performs beyond expectations.

4.7

out of

5

Great tool! It’s made my hive manufacturing so much more efficient.

4.8

out of

5

Highly efficient and reliable. The saw is a true workhorse for beekeepers.

4.9

out of

5

Exceptional quality! The saw is built to last and delivers perfect results.

4.7

out of

5

Fast shipping and amazing performance. This saw is a beekeeper’s dream!

4.8

out of

5

Precision and durability in one package. Couldn’t be happier with this purchase!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

Discover the Garden Bee Hive with Autoflow Technology—perfect for beginners and sustainable beekeeping. Easy honey extraction, durable design, and eco-friendly. Start your beekeeping journey today!

Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

Precision **hive machine** for beehive handles & frame rests. Dual 3KW motors, customizable specs, 300 pieces/hour. Boost production efficiency now!

Discover HONESTBEE's Side Bar Forming Machine, a high-efficiency bee frame machine for producing beehive frame side bars. Enhance your bee frame making machine process with our robust bee hive frame machine.

Mini Desktop Bee Hive Frame Forming Making Machine

Desktop Frame Forming Machine for bee frames, automates Langstroth and Dadant size production efficiently. Explore now!

HONESTBEE Side Bar Slicer High Speed Precision Cutting for Bee Frame Making Machine

Enhance your bee frame machine line with HONESTBEE's Side Bar Slicer. This bee hive frame machine component efficiently slices side bar blanks, crucial for any bee frame making machine process.

Automatic Finger Joints Joint Making Machine for Bee Box and Hive Making

Discover the Finger Joint Bee Box Making Machine, designed for precision and efficiency in hive production. Explore its high-speed output, durable blades, and customizable features for beekeeping needs.

Semi-Auto Bee Frame Assembly and Stapling Machine for Bee Frame

Boost bee frame assembly with our Semi-auto Stapling Machine. High efficiency, customizable options, durable construction. Perfect for beekeeping and honey production.

HONESTBEE Top Bar & Bottom Bar Forming Machine | Bee Frame Machine

HONESTBEE's Top Bar and Bottom Bar Forming Machine, a specialized bee frame machine, precisely shapes and cuts beehive frame components. Essential for any bee frame making machine setup, this robust bee hive frame machine is ideal for commercial apiaries and distributors streamlining production

Stainless Steel Beekeepers Tool Beehive Scraper for Bee Hive

Stainless steel beehive scraper: Durable 304 steel, 9-inch tool for hive maintenance. Pry, scrape, lift frames effortlessly. Ergonomic red handle for firm grip. Essential

Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

Optimize beekeeping with the Bee Frame Eyelets Fitting Machine – high-speed, precision assembly for durable, reliable hive frames. Customizable for efficiency.

HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

Discover HONESTBEE's Top & Bottom Bar Grooving Machine, an essential bee frame machine for precision slotting. Enhance your bee frame making machine process for perfect beehive frames.

Manual Honey Filling Machine Bottling Machine for Honey

Manual honey filling machine for precise, efficient packaging. Eco-friendly, durable, and customizable for small to medium-scale honey producers.

Fully Automatic Honey Filling Packaging Machine for Processing Line

Discover the efficient honey packaging machine for precise, hygienic, and automatic honey filling. Ideal for high-capacity production.

Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

Boost honey production with our high-capacity Honey Filling Machine. Achieve 1000 bottles/hour, precise filling, and minimal downtime. Enhance brand appeal effortlessly.

Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

Optimize honey packaging with our sachet and filling machines. Ensure purity, efficiency, and precision for all honey types. Upgrade production now!

Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

Boost honey production with our automatic honey filling machine. Efficient, precise, and user-friendly for high-quality bottling.

Commercial Rotary Honey Filling Machine for Production

High-precision Rotary Honey Filling Machine for commercial apiaries. Boasts ±1g accuracy, 600 jars/hour capacity, and food-grade stainless steel construction. Boost efficiency now!

Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

Optimize honey packaging with our efficient Honey Filling Machine. Precise, fast, and easy to use. Boost production now!

Metal Bee Hive Stand Bee Box Stand for Beekeeping

Elevate bee hives with our durable metal bee box stand. Protects from pests, moisture, and enhances air circulation. Perfect for beekeepers.

5 Frame Wooden Nuc Box for Beekeeping

Start your hive with a 5-frame wooden nuc box, crafted from durable China fir for optimal bee growth and insulation.

Related Articles

Beyond Standard Upgrades: Tailored Machinery Solutions from HonestBee to Modernize Your Frame & Hive Production

Mastering Bee Frame Production: A Factory-Scale Guide with Advanced Bee Frame Machine Solutions

Spring Beekeeping: Essential Steps for a Productive Season

This article outlines the crucial steps beekeepers should take in spring to ensure hive health, productivity, and a successful honey harvest.

Winter Hive Management: To Open or Not to Open?

Explore the debate on opening beehives in winter, with expert tips on preparation, monitoring, and emergency feeding to ensure colony survival.

Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization