The humble bee frame is the cornerstone of modern beekeeping, providing the essential structure for bees to build comb, raise brood, and store honey. For beekeepers and apicultural suppliers, consistent access to high-quality, precisely manufactured frames is paramount. While small-scale or manual production serves hobbyists, commercial demands necessitate a factory-level approach. This article delves into the sophisticated process of manufacturing bee frames in a large-scale factory, highlighting the specialized bee frame machinery required for each step and the immense value such production lines offer.

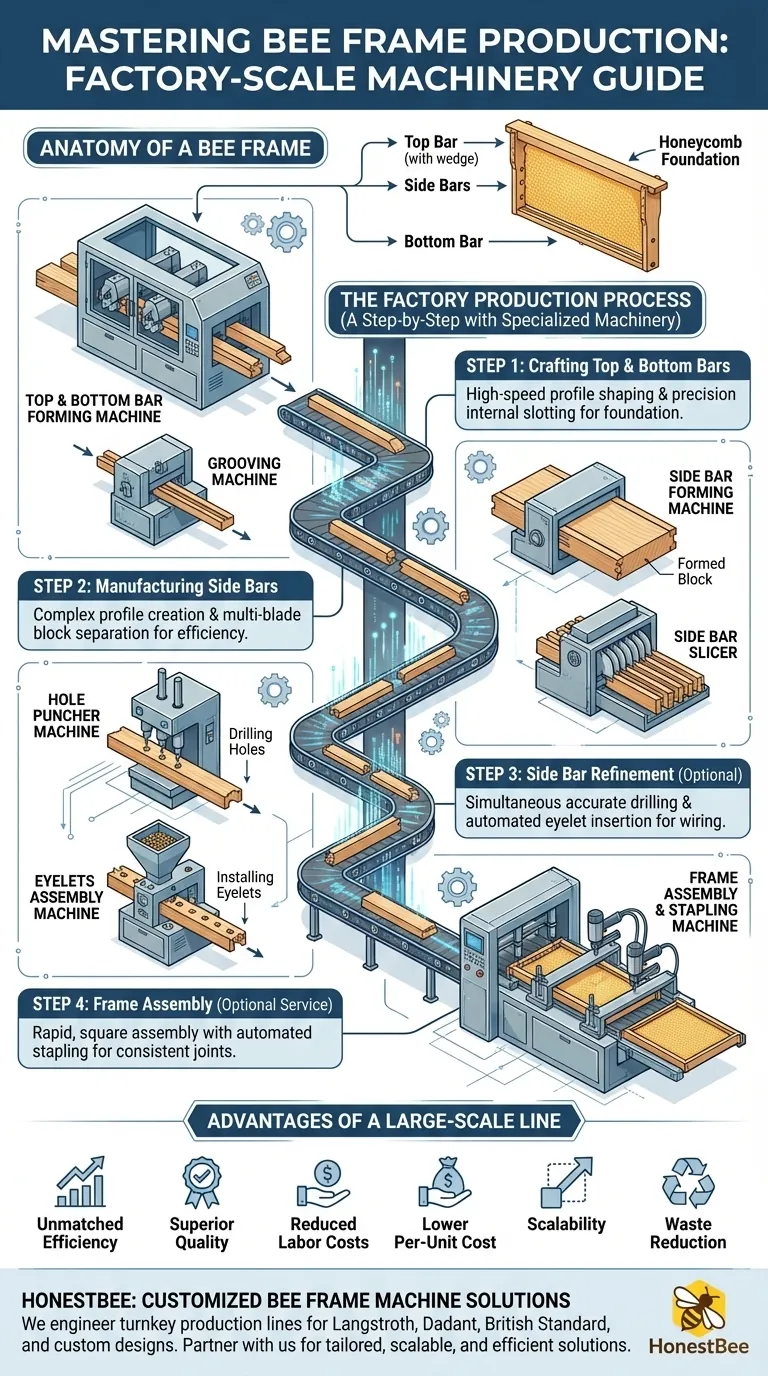

The Anatomy of a Bee Frame: Precision Components

Before diving into production, let's briefly revisit the components of a standard bee frame:

- Top Bar: The uppermost piece, often with a groove or wedge for foundation.

- Bottom Bar: The lowermost piece, typically grooved to accept foundation.

- Side Bars: Two vertical pieces connecting the top and bottom bars, often with pre-drilled holes for wiring.

Each component must be manufactured to exacting dimensions to ensure interchangeability and proper bee space within the hive.

The Factory Production Process: A Step-by-Step Guide with Specialized Bee Frame Machine Technology

A professional large-scale factory producing bee frames relies on a streamlined workflow, with dedicated machinery for each component. Here’s how it unfolds:

Step 1: Crafting Top Bars and Bottom Bars

The production of top and bottom bars, while different in their final profile, shares initial shaping and grooving machinery due to similarities in their linear nature.

A. Forming the Length and Shape: The Top Bar & Bottom Bar Forming Machine

- Function: This bee frame machine is the workhorse for producing the basic shape and precise length of top and bottom bars from raw timber stock. It typically involves multiple cutting heads, shapers, and planers integrated into a single, automated line.

- Process: Lumber is fed into the machine. It's first cut to the required length. Then, specialized cutting heads and moulders shape the wood into the specific profile required for either a top bar or a bottom bar.

- Advantages:

- High Speed & Volume: Processes hundreds of bars per hour, far exceeding manual or semi-automated methods.

- Consistency: Every bar is dimensionally identical, crucial for hive compatibility and automated assembly later.

- Reduced Labor: Significantly minimizes manual handling and cutting.

- Comparison:

- vs. Manual/Table Saws: Manual methods are slow, labor-intensive, and prone to inconsistencies in length and profile. Table saws can achieve length but struggle with complex profiles efficiently.

- vs. Basic Moulders: While basic moulders can shape profiles, a dedicated Top Bar & Bottom Bar Forming Machine integrates length cutting and specific bee frame profiles in a more optimized and high-throughput manner.

B. Creating Inner Grooves: The Grooving Machine

- Function: Once the top and bottom bars are formed, they often require a central groove on their inner face to hold the wax or plastic foundation securely. The Grooving Machine is specifically designed for this task.

- Process: Formed bars are fed into the Grooving Machine. Precisely positioned saw blades or router bits cut a consistent groove along the length of the bar. The machine can groove multiple bars simultaneously.

- Advantages:

- Precision Grooves: Ensures grooves are perfectly centered and of consistent depth and width, critical for foundation fit.

- Speed: Grooves bars much faster and more accurately than manual routing or table saw setups.

- Safety: Enclosed cutting mechanisms improve operator safety compared to open-blade manual methods.

- Comparison:

- vs. Manual Routing/Table Saw Dado: These methods are slow, less precise, and pose higher safety risks. Achieving consistent centering and depth manually is challenging for high volumes.

- Dedicated grooving on the forming machine: Some advanced forming machines might integrate grooving. However, a separate Grooving Machine can offer more flexibility, easier tool changes for different groove types, and can act as a buffer in the production line.

Step 2: Manufacturing Side Bars

Side bars have unique requirements, including specific shapes for bee space, potential tapers, and often holes for wiring.

A. Forming the Length and Shape: The Side Bar Forming Machine

- Function: This bee frame machine is engineered to produce side bars with their characteristic shapes (e.g., Hoffman self-spacing side bars, Manley-style, or simple straight sides) and precise lengths.

- Process: Similar to the top/bottom bar machine, timber is fed in. It's cut to length and then shaped by a series of cutters and moulders to create the specific profiles, including any tapers or shoulders required for proper bee spacing when frames are placed side-by-side in the hive.

- Advantages:

- Complex Profiles: Efficiently creates intricate side bar designs like Hoffman styles, which are difficult and time-consuming to produce manually.

- High Throughput: Produces a large volume of identical side bars.

- Accuracy: Ensures consistent dimensions for bee space and frame fit.

- Comparison:

- vs. Manual/Jigs: Extremely slow and inconsistent for complex profiles like Hoffman.

- vs. General Moulders: A dedicated Side Bar Forming Machine is optimized for the specific challenges of side bar profiles and often incorporates features for handling shorter pieces more effectively.

B. Separating Side Bars: The Side Bar Slicer

- Function: The side bar forming machine optimizes side bar production by first forming a wider "block" that contains the profile of multiple side bars joined together. The Side Bar Slicer is then used to accurately cut this block into individual side bars.

- Process: The pre-formed side bar block (which looks like several side bars fused side-by-side) is fed into the slicer. A series of thin-kerf, precision saw blades cut the block along predefined lines, separating it into individual, perfectly formed side bars.

- Advantages:

- Material Efficiency: Machining a wider block can sometimes be more stable and result in less waste than machining very narrow individual pieces from the start.

- Handling Efficiency: Easier to handle and process a block through initial shaping stages than many tiny individual pieces.

- High-Speed Separation: Quickly and accurately separates the block into finished side bars.

- Comparison:

- vs. Individual Forming: While individual forming is direct, the block method coupled with a slicer can be more efficient for certain profiles and wood types, maximizing throughput from the initial Side Bar Forming Machine. This is a strategic choice based on production volume and desired workflow.

Step 3: Side Bar Refinement (Optional but Common)

For frames that will be wired, additional steps are needed for the side bars.

A. Drilling Holes: The Hole Puncher Machine (or Drilling Machine)

- Function: This bee frame machine is designed to accurately drill multiple holes in the side bars simultaneously, through which wire will be threaded to support the foundation.

- Process: Side bars are fed into the machine. A set of drill bits, precisely aligned, descends to drill the required number of holes (typically 2, 3, or 4 per side bar) at consistent spacing.

- Advantages:

- Speed and Accuracy: Drills all holes simultaneously with perfect alignment, far superior to manual drilling.

- Consistency: Ensures wires will be straight and evenly tensioned.

- Reduced Labor: Automates a tedious and error-prone task.

- Comparison:

- vs. Manual Drilling/Drill Press: Extremely slow, prone to misaligned holes, and labor-intensive. Achieving consistent spacing manually across thousands of bars is nearly impossible.

B. Installing Eyelets: The Eyelets Assembly Machine

- Function: Eyelets (small metal grommets) are inserted into the drilled holes in side bars to prevent the support wire from cutting into the wood when tensioned, prolonging frame life. The Eyelets Assembly Machine automates this insertion.

- Process: Side bars with pre-drilled holes are fed into the machine. Hoppers supply eyelets, which are automatically oriented and pressed into the holes.

- Advantages:

- Speed: Installs eyelets far faster than manual methods.

- Secure Fit: Ensures eyelets are properly seated, preventing them from falling out.

- Reduced Tedium: Automates a very fiddly and repetitive task.

- Comparison:

- vs. Manual Eyelet Pliers: Very slow, causes hand fatigue, and can result in inconsistently set eyelets. For factory scale, manual eyeleting is not feasible.

Step 4: Frame Assembly (Optional Service for End-Users)

If the factory also offers assembled frames, a final machine comes into play.

A. Assembling and Stapling: The Frame Assembly and Stapling Machine

- Function: This bee frame machine takes the manufactured top bars, bottom bars, and side bars and automates the process of assembling them into complete frames, securing the joints with staples or nails.

- Process: Operators load the components into jigs or magazines. The machine aligns the parts, presses them together, and pneumatic staplers/nailers secure the joints. The assembled frame is then ejected.

- Advantages:

- Rapid Assembly: Assembles frames much faster than manual methods.

- Squareness & Consistency: Ensures frames are assembled squarely and joints are consistently tight.

- Reduced Labor Cost: Significantly cuts down on the labor required for assembly.

- Comparison:

- vs. Manual Assembly (Hammer & Nails/Stapler): Slow, labor-intensive, and can result in inconsistently assembled or non-square frames.

- vs. Assembly Jigs with Manual Stapling: Jigs improve squareness, but a fully automated machine integrates the clamping and fastening for superior speed and ergonomics.

Advantages of a Large-Scale Bee Frame Production Line

Investing in a comprehensive bee frame machine production line offers transformative benefits:

- Unmatched Efficiency & Throughput: Automated lines produce thousands of frames or components per day, meeting large-scale demand.

- Superior Quality & Consistency: Machine precision ensures every frame component is dimensionally accurate, leading to perfectly fitting frames that respect bee space and are interchangeable.

- Reduced Labor Costs: Automation minimizes manual intervention, reducing labor expenses and freeing up staff for quality control or other tasks.

- Lower Per-Unit Cost: High-volume production and reduced labor lead to a significantly lower cost per frame, enhancing profitability.

- Scalability: Production can be easily scaled up or down by adjusting machine run times, without the linear increase in labor that manual processes require.

- Waste Reduction: Optimized cutting and forming processes can minimize wood waste compared to less precise methods.

Application Scenarios & Strategic Value for Bee Frame Producers

A factory-scale bee frame machine line is ideal for:

- Large Commercial Apiaries: Producing their own frames in-house for cost savings and quality control.

- Beekeeping Equipment Suppliers: Manufacturing frames for wholesale and retail distribution.

- Specialized Wood Product Manufacturers: Diversifying into the apicultural market.

The Strategic Value: Investing in such a production line is not just an operational upgrade; it's a strategic move. It allows a business to:

- Become a Market Leader: By offering high-quality frames at competitive prices.

- Control the Supply Chain: Reducing reliance on external suppliers.

- Offer Customization: Efficiently produce various frame types.

- Enhance Brand Reputation: Associated with precision-engineered, reliable products.

HonestBee: Your Partner for Customized Bee Frame Machine Solutions

At HonestBee, we understand that "one size fits all" doesn't apply to global beekeeping. Different regions and beekeeping philosophies utilize various frame styles. That's why we specialize in providing comprehensive, customized bee frame machine production line solutions.

Whether you need to produce:

- Langstroth frames (the global standard)

- Dadant frames (popular in Europe and parts of the US)

- British Standard frames

- Or any other specialized or custom frame design

HonestBee can engineer and deliver a turnkey production line tailored to your exact specifications. We work with you to understand your volume requirements, desired level of automation, and specific frame designs. Our expertise covers every machine detailed above, from individual units to fully integrated lines.

We don't just sell machines; we provide solutions that empower your bee frame production enterprise with:

- Tailored Design: Machines configured for your specific frame dimensions and profiles.

- Scalability: Solutions that can grow with your business.

- Technical Support & Training: Ensuring your team can operate and maintain the equipment effectively.

- Efficiency & Profitability: Helping you achieve a competitive edge in the market.

Conclusion: Revolutionizing Bee Frame Manufacturing

The transition from manual or semi-automated bee frame production to a fully-fledged factory line equipped with specialized bee frame machinery is a game-changer. It offers unparalleled advantages in efficiency, consistency, cost-effectiveness, and scalability. For businesses looking to dominate the bee frame market or secure a reliable, high-quality internal supply, investing in such technology is a strategic imperative.

HonestBee stands ready to be your partner in this transformation, offering bespoke bee frame machine solutions that will set your production apart. Contact us today to discuss how we can help you build the future of bee frame manufacturing.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- HONESTBEE Top Bar & Bottom Bar Forming Machine | Bee Frame Machine

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

Related Articles

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- Unlock Peak Efficiency: The HONESTBEE Bee Frame Machine for Flawless Frame Assembly

- Scaling Up Your Beekeeping Operation: How an HonestBee Bee Frame Machine Fuels Growth

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization