In the dynamic world of beekeeping, the demand for high-quality, durable beehives and frames is ever-increasing. For large-scale manufacturers, meeting this demand efficiently while maintaining superior quality requires more than just standard equipment; it necessitates a strategic investment in specialized, high-performance machinery. HonestBee stands at forefront of this evolution, offering comprehensive, tailored hive machine and bee frame machine solutions designed to propel your production capabilities into the future.

This article will delve into the intricate processes of bee frame and hive manufacturing, explore the advanced machinery required, and highlight how HonestBee’s customized production lines can become a cornerstone of your operational success and strategic advantage.

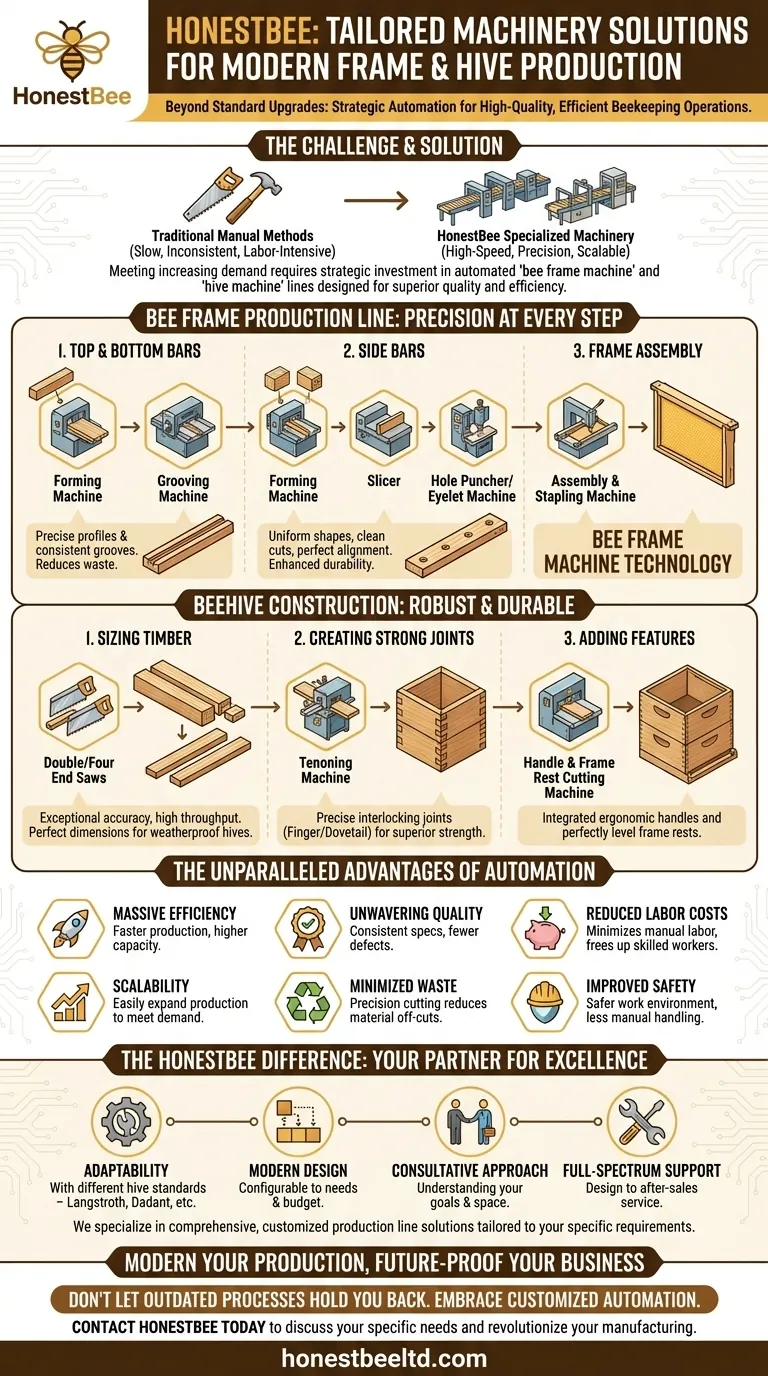

The Intricate Craft of Bee Frame Production: Precision at Every Step

Bee frames are the heart of the hive, providing the essential structure for bees to build comb, raise brood, and store honey. Producing them in large quantities with consistent quality requires a series of precise operations, each optimized by specialized bee frame machine technology.

1. Crafting Top and Bottom Bars: The Foundation of the Frame

The top and bottom bars define the frame's primary dimensions and structural integrity.

- Machine: Top Bar & Bottom Bar Forming Machine

- Function: This crucial machine precisely cuts and shapes wood to the exact lengths and profiles required for top and bottom bars (e.g., Hoffman-style top bars, grooved bottom bars).

- HonestBee Advantage: Our forming machines ensure unparalleled accuracy in dimensions and profile, leading to perfectly fitting frames. This automation drastically reduces manual labor and material waste compared to traditional table saws or multi-step manual processes.

- Machine: Grooving Machine

- Function: Working in tandem with the forming machine, the grooving machine carves the essential inner groove into the top and bottom bars. This groove holds the foundation (wax or plastic) securely.

- HonestBee Advantage: Precise, consistent grooves are vital. Our machines ensure uniform depth and width, preventing foundation slippage and making assembly easier, a stark contrast to manual routing which can be inconsistent and slower.

![frame making machine]()

2. Manufacturing Side Bars: Strength and Support

Side bars provide the vertical support and spacing within the hive.

- Machine: Side Bar Forming Machine

- Function: This machine processes wood blocks into side bars of the correct length, width, and specific profile (e.g., Hoffman self-spacing, Manley, or straight).

- HonestBee Advantage: Delivers consistently shaped side bars at high speed, ensuring uniformity that is critical for proper frame spacing and hive inspection. This replaces less precise and more labor-intensive methods.

- Machine: Side Bar Slicer

- Function: After the side bar blocks are formed with their intricate profiles, the slicer precisely separates these blocks into individual side bars.

- HonestBee Advantage: Achieves clean, accurate cuts, maximizing yield from each block and minimizing waste, far superior to manual band-sawing or less specialized slicing.

- Optional - Machine: Hole Puncher Machine

- Function: For frames that will be wired, this machine accurately drills holes through the side bars.

- HonestBee Advantage: Ensures perfectly aligned holes at consistent spacing, critical for easy and effective wiring. This automated process is significantly faster and more accurate than manual drilling.

- Optional - Machine: Eyelets Assembly Machine

- Function: If eyelets are desired to protect the wood and wire, this machine automatically inserts and secures metal eyelets into the pre-drilled holes.

- HonestBee Advantage: Provides a rapid, consistent application of eyelets, enhancing frame durability and preventing wire from cutting into the wood – a tedious and time-consuming manual task otherwise.

![bee frame machine]()

3. Assembling the Frame: Bringing It All Together

- Machine: Frame Assembly and Stapling Machine

- Function: This machine takes the manufactured top, bottom, and side bars, clamps them together in a perfectly square jig, and automatically staples or nails them, completing the frame.

- HonestBee Advantage: Guarantees perfectly square and securely fastened frames at a high rate of production. This automated assembly offers superior consistency and speed over manual jigging and stapling, reducing operator fatigue and improving output quality. This is a core piece of any efficient bee frame machine line.

![bee frame machine]()

Constructing Robust Beehives: The Art of the Hive Machine

A beehive's primary role is to protect the colony from the elements and provide a secure, manageable environment. Precision-engineered components are key to a long-lasting, effective hive.

1. Sizing and Preparing Timber: The Building Blocks

- Machine: Double End Saw or Four End Saw

- Function: These powerful saws are used to accurately cut lumber to the precise lengths and widths required for hive bodies, supers, bottoms, and lids. A four-end saw can process all four sides in a single pass.

- HonestBee Advantage: Delivers exceptional cutting accuracy and high throughput. Compared to single-blade saws or manual measurements, these machines ensure that all components are perfectly dimensioned, which is crucial for tight-fitting, weatherproof hives. This significantly reduces setup time and material handling.

2. Creating Strong Joints: Ensuring Durability

The joints are critical for the hive's structural integrity and longevity.

- Machine: Tenoning Machine (for Finger Joints or Dovetail Joints)

- Function: This specialized hive machine cuts precise finger joints (box joints) or dovetail joints into the edges of the hive body components.

- Finger Joints: Offer a large gluing surface and good strength, relatively easier to machine.

- Dovetail Joints: Provide superior mechanical strength and a classic look, often preferred for premium hives.

- HonestBee Advantage: Our tenoning machines create perfectly interlocking joints that are significantly stronger and more weather-resistant than simpler butt joints or nailed connections. Automated joint cutting ensures consistency that is nearly impossible to replicate manually at scale, leading to hives that last longer and withstand harsh conditions.

- Function: This specialized hive machine cuts precise finger joints (box joints) or dovetail joints into the edges of the hive body components.

3. Adding Essential Features: Functionality and Ergonomics

- Machine: Handle and Frame Rest Cutting Machine

- Function: This versatile machine creates the internal recessed handholds for lifting hive bodies and mills the precise "frame rest" ledge on which the bee frames hang.

- HonestBee Advantage: Integrates multiple operations, ensuring that handles are comfortable and frame rests are perfectly level and dimensioned. This precision prevents frames from rocking or being too tight, facilitating easier hive inspections. This specialized hive machine automates what would otherwise be multiple, time-consuming routing or manual cutting steps.

The Unparalleled Advantages of a Large-Scale Automated Production Line

Investing in a comprehensive, automated production line from HonestBee offers transformative benefits for bee frame and hive manufacturers:

- Massive Efficiency & Output: Automated machines operate faster and longer than manual methods, dramatically increasing production capacity.

- Unwavering Quality & Precision: Machine-driven processes ensure every component and assembled product meets exact specifications, reducing defects and improving overall product quality.

- Reduced Labor Costs: Automation minimizes the need for extensive manual labor, freeing up skilled workers for other critical tasks and reducing per-unit labor costs.

- Scalability: Production lines can be scaled to meet growing demand without a proportional increase in labor or space.

- Minimized Material Waste: Precision cutting and forming reduce errors and off-cuts, leading to better material utilization.

- Improved Worker Safety: Automated systems reduce manual handling of sharp tools and heavy materials, creating a safer work environment.

Application Scenarios: Automated lines are ideal for:

- Large commercial beekeeping suppliers.

- Businesses exporting frames and hives internationally.

- Cooperatives looking to centralize and standardize production for their members.

- Manufacturers aiming to significantly increase market share through superior efficiency and quality.

The HonestBee Difference: Your Partner for Tailored Production Excellence

At HonestBee, we understand that "one size fits all" doesn't apply to modern apiary equipment manufacturing. That's why we specialize in comprehensive, customized production line solutions.

- Adaptability to All Standards: Whether you produce Langstroth, Dadant, British National hives and frames, or have unique regional or proprietary designs, we can engineer a bee frame machine and hive machine line tailored to your specific requirements.

- Modular Design: Our solutions can be configured to match your current needs and budget, with the flexibility to add more automation or capacity as your business grows.

- Consultative Approach: We work closely with you to understand your production goals, space constraints, and desired output, designing a line that is a perfect fit.

- Full-Spectrum Support: From initial design and manufacturing to installation, training, and after-sales service, HonestBee is your dedicated partner.

Why HonestBee's Machinery is a Strategic Advantage

Each HonestBee machine is designed for optimal performance, offering clear advantages over traditional or less specialized methods:

- Forming & Grooving Machines vs. Manual/Semi-Auto: Unmatched speed, precision in profiles and groove depth, and consistency. Eliminates human error and variability.

- Side Bar Slicers vs. Band Saws: Cleaner cuts, higher yield, enhanced safety, and greater accuracy for complex profiles.

- Automated Punching/Eyeletting vs. Manual: Drastically increased speed, perfect alignment, and consistent eyelet setting for improved frame longevity.

- Frame Assembly Machines vs. Manual Assembly: Ensures every frame is square and securely fastened, at a pace unachievable manually, reducing bottlenecks.

- Multi-End Saws vs. Single Saws: Exponentially faster processing of timber with superior accuracy, reducing handling and setup times.

- Specialized Tenoning Machines vs. Manual/Simpler Joinery: Creates vastly stronger, more durable, and weather-resistant joints, enhancing the lifespan and value of your hives.

- Handle & Frame Rest Cutters vs. Manual Routing: Guarantees uniform handles and perfect frame rests efficiently, improving usability and hive functionality.

Investing in an HonestBee production line is not just an equipment upgrade; it's a strategic move to:

- Dominate Your Market: Produce higher quality products more efficiently than competitors.

- Enhance Profitability: Reduce costs through automation and minimized waste.

- Build a Reputation for Excellence: Consistently deliver superior frames and hives.

Modernize Your Production, Future-Proof Your Business

The future of bee frame and hive manufacturing lies in intelligent automation and tailored solutions. HonestBee provides the expertise and the advanced bee frame machine and hive machine technology to transform your production facility into a model of efficiency and quality.

Don't let outdated processes hold you back. Embrace the power of customized automation.

Contact HonestBee today to discuss your specific production needs and discover how our tailored machinery solutions can revolutionize your frame and hive manufacturing, giving you a distinct competitive edge.

Visual Guide

Related Products

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- HONESTBEE Top Bar & Bottom Bar Forming Machine | Bee Frame Machine

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Engraved Round Hive Number Tags for Beekeeping

Related Articles

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Beyond the Scraper: Why Your Frame Cleaning Method Might Be Harming Your Apiary

- How Bee Box-Making Machines Transform Beekeeping Efficiency and Sustainability