Are you a commercial beekeeping equipment supplier, a large-scale apiarist, or a woodworking specialist tired of the bottlenecks in bee frame production? Do inconsistent quality, slow turnaround times, and high labor costs eat into your profits and hinder your growth? Imagine transforming a raw stack of timber into perfectly profiled side bar blanks, ready for slicing, with unparalleled speed and precision. That's not just a dream; it's the reality offered by our Bee Frame Side Bar Forming Machine.

This isn't just another piece of woodworking equipment; it's a strategic investment designed to propel your bee frame manufacturing into a new era of productivity.

From Bottleneck to Powerhouse: Witness the Transformation

Our bee frame machine is a masterclass in automated efficiency:

- Effortless Infeed: Simply stack your timber planks, and the machine's robust roller system takes over, feeding material smoothly and consistently.

- Precision Engineering in Motion: Multiple high-speed, industrial-grade motors drive specialized cutting heads. In a single pass, these heads meticulously mill all the essential top and bottom grooves and shape the end profiles.

- Perfect Length, Every Time: An integrated cutting unit then precisely trims the continuously formed timber into your exact specified side bar blank lengths.

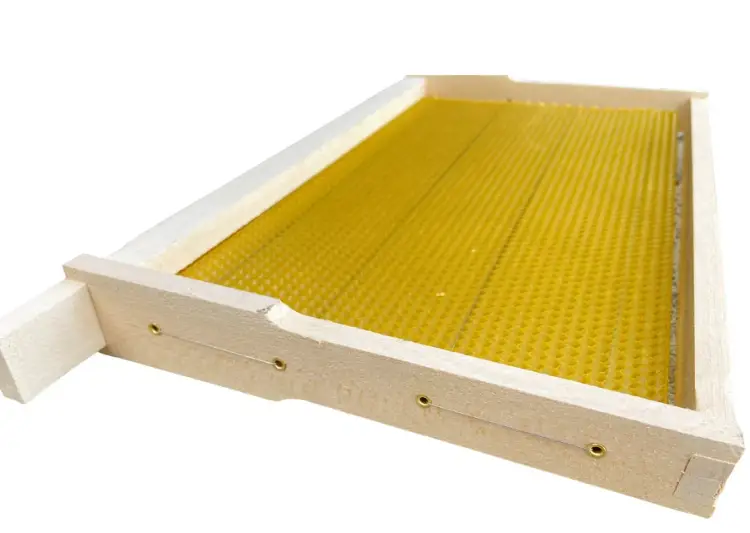

- Quality You Can Measure: The output is a perfectly formed, multi-bar blank.

Why This Bee Frame Machine is a Game-Changer for Your Business

Traditional methods, whether manual or using general-purpose tools, simply can't compete. They're often slow, demand intensive labor, lead to inconsistencies, and struggle to scale. Our specialized Bee Frame Side Bar Forming Machine addresses these pain points directly, offering a suite of benefits that translate into tangible business growth:

1. Skyrocket Your Production & Meet Demand Head-On

- The Advantage: Massively accelerates the initial forming stage of side bar production. What used to take hours can now be accomplished in a fraction of the time.

- Your Gain: Significantly increase your output capacity, allowing you to fulfill larger orders, reduce lead times, and capitalize on seasonal demand without the stress.

2. Slash Labor Costs & Boost Your Bottom Line

- The Advantage: Automation drastically reduces the manual labor required for shaping and grooving.

- Your Gain: Free up skilled workers for other valuable tasks, reduce your reliance on manual labor, and see a direct positive impact on your production costs and profit margins.

3. Guarantee Unwavering Quality & Consistency

- The Advantage: Every formed blank produced is a precise replica of the last. No more variations from piece to piece.

- Your Gain: Deliver a consistently superior product to your customers. Perfect-fitting frames mean happier bees and happier beekeepers, enhancing your brand reputation.

4. Embrace Ultimate Customization: Your Frames, Your Way

- The Advantage: This is where our bee frame machine truly shines. We understand that one size doesn't fit all in the beekeeping world.

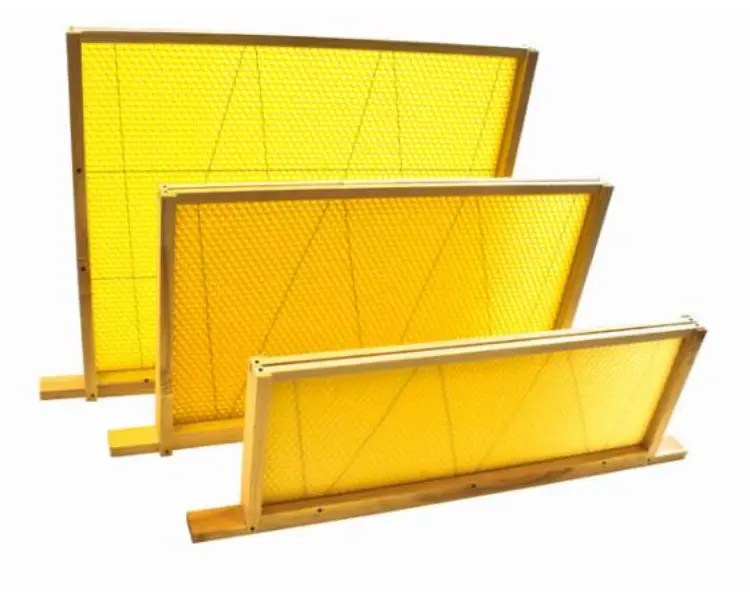

- Adaptable to ALL Major Frame Styles: Langstroth, Dadant, British Standard, National, Smith, Modified Commercial – you name it. We can configure the cutting heads and guides to produce the exact profiles for your chosen frame type.

- Your Specific Dimensions: Need a unique groove depth, a special end profile, or a non-standard length? We tailor the machine to your precise specifications.

- Global Voltage Compatibility: We'll build your machine to match your local power supply (three-phase 380V or 220V).

- Your Gain: Cater to diverse market needs, offer specialized products, and become the go-to supplier for even the most niche frame requirements. No more turning away customers because their needs are "too specific."

Operational Excellence & Safety: Designed with You in Mind

While delivering powerful performance, we haven't overlooked the practicalities:

- Intuitive Controls: The clearly labeled control panel (green for go, red for stop, emergency cut-offs) ensures ease of use and immediate response.

- Built to Last: Heavy-duty steel construction and quality components mean this machine is built for the rigors of industrial use, ensuring years of reliable service.

- Safety as a Priority: Equipped with necessary guards and clear operational guidelines. Always ensure operators use appropriate PPE (glasses, hearing protection, dust masks).

- Clean Operation: Designed with efficient dust extraction points to connect to your workshop's system, promoting a healthier and cleaner environment.

- Maintenance Made Manageable: Easy access for routine checks, blade sharpening/replacement, and lubrication.

The Journey to a Finished Side Bar

It's important to understand that this Bee Frame Side Bar Forming Machine is the first critical step in high-volume production. It creates the perfectly profiled blank. The next step involves using a Side Bar Slicer (which we can also discuss!) to efficiently cut this formed blank into multiple individual, ready-to-assemble side bars. This two-step specialized process is the key to achieving maximum throughput and quality.

Is This Machine Right for You?

If you answer "YES" to any of the following, then this bee frame machine is a strategic asset you need to consider:

- Are you struggling to keep up with demand for bee frames?

- Are labor costs a significant portion of your frame production expenses?

- Do you face challenges maintaining consistent quality across batches?

- Do you want the flexibility to produce various frame styles (Langstroth, Dadant, etc.) and custom orders?

- Are you looking to scale your beekeeping equipment business and improve profitability?

Take Control of Your Bee Frame Production Today!

Stop letting outdated methods dictate your output and profitability. It's time to invest in a solution that delivers speed, precision, quality, and the unparalleled flexibility to meet any customer demand. Our Bee Frame Side Bar Forming Machine is more than just machinery; it's your pathway to market leadership and enhanced operational efficiency.

Ready to discuss how this customizable powerhouse can transform your workshop and your bottom line?

Contact us today for a personalized consultation. Let's explore your specific needs – whether for Langstroth, Dadant, British Standard, or any custom frame design – and configure the perfect bee frame machine solution for your business.

Visual Guide

Related Products

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Mini Desktop Bee Hive Frame Forming Making Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

Related Articles

- How the Beehive Frame Machine Transforms Apiary Equipment Production

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- How Automated Frame-Making Revolutionizes Beehive Production Efficiency

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine