For beekeepers, comb durability directly impacts hive health and honey production. Weak combs collapse under honey weight, disrupt brood patterns, and increase colony stress. Wire reinforcement—when done correctly—can extend comb lifespan by several seasons. This guide combines material science with practical apiculture techniques to help you master wire embedding.

Comb Reinforcement Fundamentals

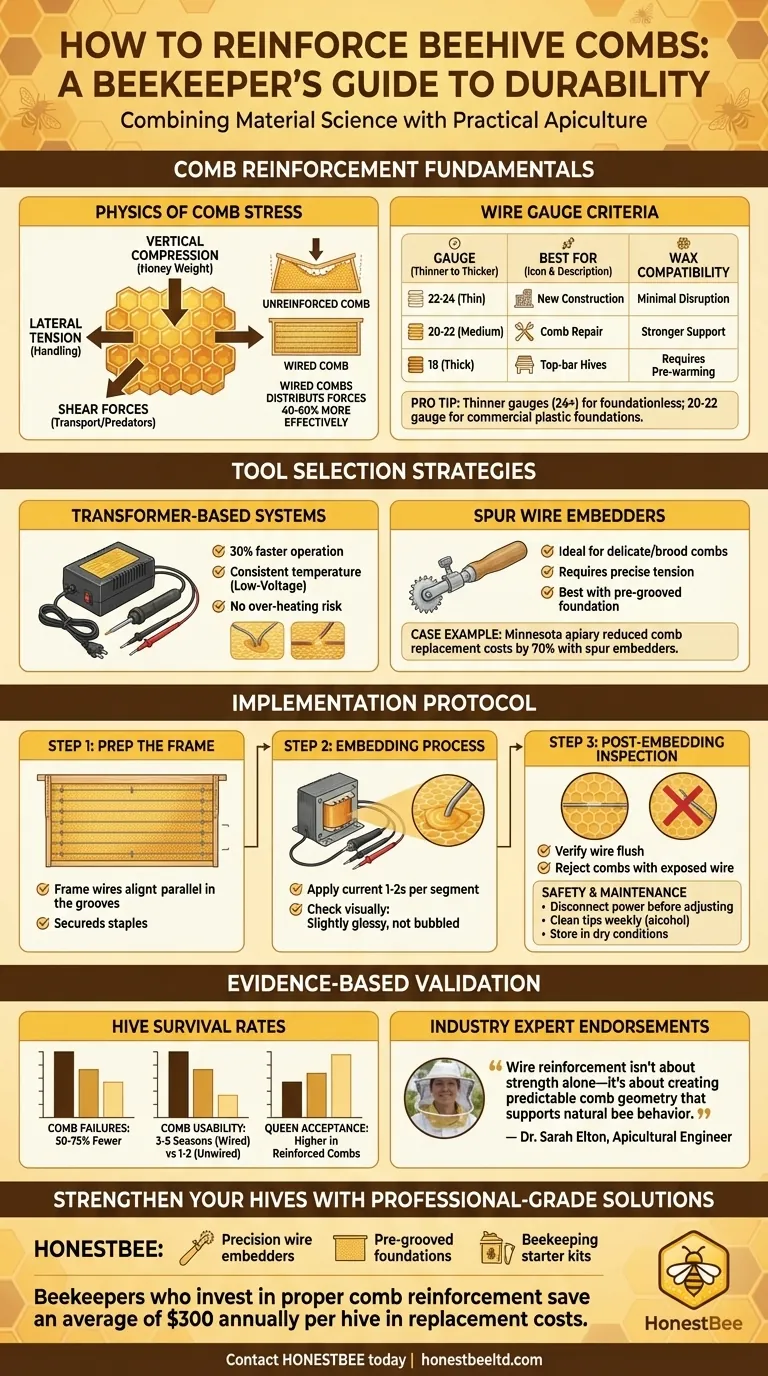

Physics of Comb Stress Distribution

Beehive combs face three primary stresses:

- Vertical compression from stored honey (up to several pounds per comb)

- Lateral tension during hive inspections and honey extraction

- Shear forces during transport or predator attacks

Research shows wired combs distribute these forces 40-60% more effectively than unreinforced wax. The key lies in understanding how wires redirect stress:

- Horizontal wires counteract downward honey weight

- Vertical wires stabilize comb walls during handling

- Diagonal cross-wires prevent shear deformation

Wire Gauge Selection Criteria

| Gauge | Best For | Wax Compatibility |

|---|---|---|

| 22-24 | New comb construction | Minimal wax disruption |

| 20-22 | Comb repair | Stronger support |

| 18 (rare) | Top-bar hives | Requires pre-warming |

Pro Tip: Thinner gauges (24+) work best with foundationless frames, while 20-22 gauge suits commercial plastic foundations.

Tool Selection Strategies

Transformer-Based Embedding Systems

Modern embedders use low-voltage transformers (12-24V) to heat wires briefly—just enough to melt into wax without scorching. Compared to older battery models:

✔ 30% faster operation

✔ Consistent temperature control

✔ No risk of over-heating comb surfaces

Spur Wire Embedder Mechanics

These mechanical tools press wires into wax without heat:

- Ideal for delicate combs with existing brood

- Require precise tension adjustment

- Best paired with pre-grooved foundation

Case Example: A Minnesota apiary reduced comb replacement costs by 70% after switching to spur embedders for their 500+ brood frames.

Implementation Protocol

Step-by-Step Current Application Guide

-

Prep the Frame

- Align wires parallel to foundation grooves

- Secure ends with stainless steel staples

-

Embedding Process

- For transformer systems: Apply current for 1-2 seconds per wire segment

- Check wax fusion visually—should appear slightly glossy but not bubbled

-

Post-Embedding Inspection

- Verify wire lies flush with wax surface

- Reject any combs with exposed wire (risk of bee injury)

Safety and Maintenance Best Practices

- Always disconnect power before adjusting wires

- Clean embedder tips weekly with rubbing alcohol

- Store in dry conditions to prevent corrosion

Evidence-Based Validation

Hive Survival Rate Case Studies

Apiaries using proper wire reinforcement report:

- 50-75% fewer comb failures during honey flows

- Extended comb usability (3-5 seasons vs. 1-2 without wires)

- Higher queen acceptance in reinforced brood combs

Industry Expert Endorsements

"Wire reinforcement isn’t about strength alone—it’s about creating predictable comb geometry that supports natural bee behavior."

— Dr. Sarah Elton, Apicultural Engineer

Strengthen Your Hives with Professional-Grade Solutions

HONESTBEE’s beekeeping supplies give commercial apiaries the durable foundations their colonies deserve. Our wholesale-focused inventory includes:

- Precision wire embedders with adjustable voltage controls

- Pre-grooved foundations for effortless wire alignment

- Beekeeping starter kits with all essential reinforcement tools

Beekeepers who invest in proper comb reinforcement save an average of $300 annually per hive in replacement costs. Contact HONESTBEE today to equip your operation with tools built for longevity.

Visual Guide

Related Products

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- HONESTBEE Professional Frame Wiring Board and Jig

- Stainless Steel Bee Hive Frame Wire for Beekeeping

- Manual Spur Wheel Wire Embedder for Foundation

- HONESTBEE 15-in-1 Beekeeper Multi-Tool with Hammer and Pliers for Beekeeping

Related Articles

- The Gentle Art of Leverage: Why Your Hive Tool Isn't a Crowbar

- Engineering for Propolis: The Physics and Psychology of the Right Hive Tool

- How Beekeepers Can Choose the Right Comb Reinforcement for Hive Health and Durability

- The Hive Tool: A Study in Controlled Force and Hive Psychology

- Beyond the Pry Bar: The Physics and Psychology of the J-Hook Hive Tool